LEARN ABOUT 7 3D PRINTING TECHNOLOGIES.

HOW TO CHOOSE THE RIGHT 3D PRINTING TECHNOLOGY FOR YOUR BUSINESS.

Product Description

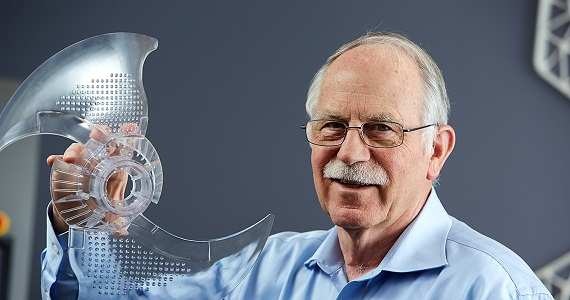

Chuck Hull – Father of the 3D printing industry Chuck Hull – Father of the 3D printing industry | 3D Systems was founded in Valencia, California (USA) by Chuck Hull – President – Founder – The person who laid the foundation for the world’s first SLA 3D printer production technology since the 80s of the century. ago. He is the holder of over 30 exclusive patents on 3D printing technology. He was nominated for the “European Inventor” award and is a pioneer in the field of 3D printing – one of the fields creating the 4th Industrial Revolution – the Digital World Revolution. |

3D Systems is still the leader in the world market for 3D printers, with about 1,000 workers and listed on the NASDAQ technology stock market. Hull’s idea of entering the third dimension with a printing press was imitated by many people. Today, in the 3D printing market, there are thousands of companies participating, offering nearly identical 3D printing equipment. Wohlers Associates estimates that the industry’s revenue in the world market in 2012 will be about 2 billion USD, will increase to 3 billion in 2016, and reach 10 billion in 2024. Of which 3D SYSTEMS accounts for 70% of the market share. and growing steadily every year from 40 to 50%, affirming the position of “Father” leading the 3D printing industry worldwide.

3D Systems was founded in Valencia, California (USA) and President Chuck Hull

7 3D PRINTING TECHNOLOGY OF 3D SYSTEMS

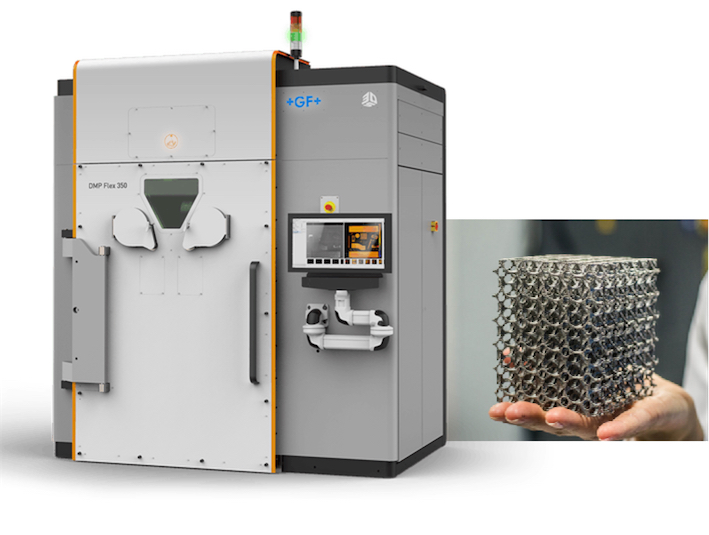

1. DMP – Direct Metal Printting

DMP technology uses high-intensity lasers to melt and bond each layer of metal powder. Then use UV light to harden. The 3D printer for metal materials with mechanical properties of the material 90-98% similar to the original material is a remarkable achievement of 3D Systems.

- Metal 3D printing with lower component costs

- Reduced weight of components/Light weight design

- Reduce the number of parts / Optimize and simplify assembly details

- Optimize topologies/ Mass customization

- Repeatable, uniform quality throughout the construction area

- High productivity

- Print large prototype parts, functional parts.

- Enhance fluid flow

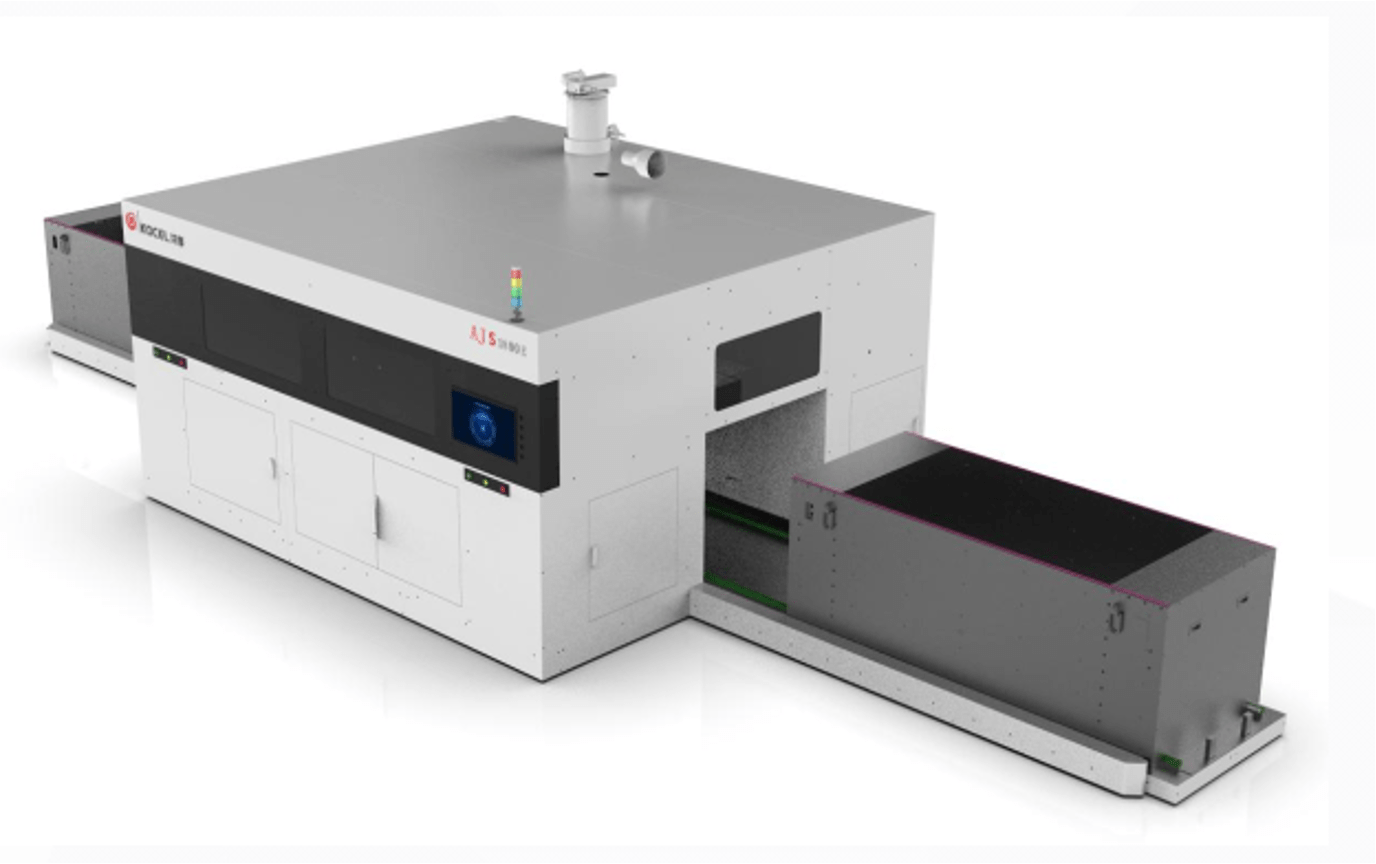

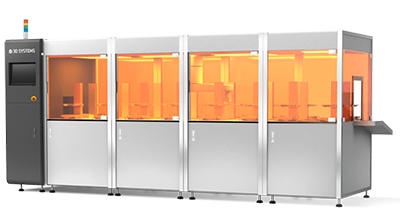

3D PRINTER LINE METAL MATERIALS

Powerful integrated material management to scale production

- High throughput, high repeatability. Quick and easy material changes

- Produce seamless large-size patterns. Stable environment, low O 2 concentration

- Low TCO to expand production. Exclusive software: 3DXpert

|

|

DMP Flex 350, DMP Flex 350 Dual and DMP Flex 350 Triple

Dimension: 275 x 275 x 420 mm |

DMP Factory 350 and DMP Factory 350 Dual

Dimension: 275 x 275 x 420 mm |

|

DMP Flex 100 + 200 |

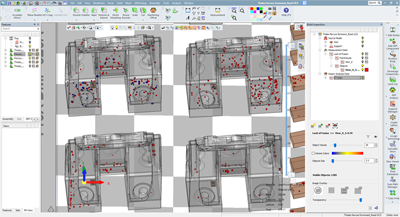

Software Automatically refines the batch printing process |

Software for monitoring batch printing processes |

|

DMP Flex 100 100 x 100 x 90 mm DMP Flex 200 140 x 140 x 115 mm The printer prints sharp details and can print thin-walled samples. Smooth surface. Competitive price |

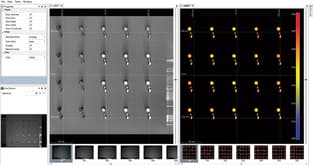

Minimize secondary inspection in the 3D printing process with validated automated analysis |

Real-time process monitoring to make informed decisions about product quality |

| FEATURE | MATERIALS | APPLICATIONS |

|---|---|---|

| – DMP technology used for direct metal printing. – High precision. DMP print layer resolution is adjustable to reach 5 μm – Intuitive, easy-to-use 3D printing software | – Use powdered metal materials: stainless steel, aluminum, titanium, cobalt, chrome… to make 3D printing materials. – Materials used for dentistry have been NiCor certified. Pure, dense ingredients without porosity – Mechanical properties of the material are 90-98% similar to the original (pure) material. | – Reduced weight/lightweight design. – Structure optimization – Direct printing of molds and replacement parts – Orthopedics and spinal cord transplantation – Dentistry |

2. SLA – Stereolithography

| This is the first 3D printing technology in the world, researched and developed by Chuck Hull in 1980. Up to now, this technology has developed to the pinnacle of solution printing with precision levels up to (+/ – 45 μm) affirms the power and importance of SLA technology in the field of 3D printing. |  Finger 4 solution (SLA) 3D printer |

.jpg) (SLA) Projet 6000 / 7000HD (SLA) Projet 6000 / 7000HD |  (SLA) ProX 800 / 950 (SLA) ProX 800 / 950 |  (SLA) PRJ 1200 (SLA) PRJ 1200 |

| PRINCIPLES OF OPERATION | FEATURES | MATERIALS | APPLICATIONS |

| – Liquid Resin material dipped into the solution tray. SLA uses a light source that passes through a mirror that cures each printed layer using UV light. SLA printing layer can reach from 0.06, 0.08, 0.1,… mm. – For 3D printing technologies using plastic materials, this is the technology that creates 3D printed products with the most beautiful surfaces, can be used immediately, and has high resolution. |

– Vertical (cylindrical) printing technology. Prints 4x faster than the competition (Same technology) – 2.5 times more resolution than competitors (Same technology) – Smooth surface, precision level (+/- 45 μm) |

– Plastic can withstand high temperatures – Plastic has ingredients for jewelry and jewellery. – Plastic for dentistry – Heat resistant plastic – White, black, gray ABS-like plastic instead of being processed on CNC machines. Flexible polyproplene plastic for molding (PP). – Transparent plastic |

– Molds for vacuum casting – Molded metal molded shell – Complex detailed clusters – Wind tunnel model – Production of drilling rigs for testing – Orthopedic dentistry – Assembly equipment |

3. MJP – Multijet Printing ( Polyjet)

- Unlike other 3D printers with the same technology on the market, MJP’s post-print support layer can self-melt in the thermal solution. This is especially important when you’re printing difficult parts: thin edges, parts with many interlocking or obscured slots.

- The printed material has mechanical properties 90%-98% similar to the original material, helping the product not deform or warp after use. MJP technology can now print the widest range of materials of any 3D printer.

- Printing speed is 2 times faster, – Post-print processing time is 4 times faster than similar technology 3D printers

Projet MJP 2500 Plus (Detal) / 2500 Series / 2500 W Projet MJP 2500 Plus (Detal) / 2500 Series / 2500 W |  MJP 3600Series / 3600W Series MJP 3600Series / 3600W Series |   MJP 5600 MJP 5600 |

Xem chi tiết các máy in 3d – Công nghệ in MJP tại: https://scantechvn.com/may-in-3d-da-vat-lieu-mjp

| PRINCIPLES OF OPERATION | FEATURES | MATERIALS | APPLICATIONS |

|---|---|---|---|

| MJP technology uses UV rays to sinter liquid material sprayed by more than 1000 fine micro nozzles. The wax support layer fills the gaps of the material to create a solid, solid block. DMP is divided into 2 lines: Direct Metal Printing (multi-material) and Direct Metal Printing Wax (for direct casting) | – MJP uses a waxy support layer. After printing, the wax layer will automatically melt in the solution without the need for pressure spraying or manual prying. So any thin edges or complex profiles can be printed perfectly. The printed material has mechanical properties 95 – 100% similar to the original material. No deformation or warping after long periods of use | Rubber, wax, transparent plastic, hard plastic, soft plastic, elastic plastic, heat-resistant plastic, load-bearing plastic, synthetic plastic… Some MJP 3d printer lines can mix different types of materials on the same product. | – Design and manufacture new products R&D Test samples Create 3D printed models from wax for direct metal mold casting: Jewelry, Dentistry, Maxillofacial Molds: Blow molds, casting molds, sand molds, plastic molds… |

4. SLS – Selective Laser Sintering

Pro 60 HD – HS Pro 60 HD – HS |  ProX SLS 500 ProX SLS 500 |

| PRINCIPLES OF OPERATION | FEATURES | MATERIALS | APPLICATIONS |

|---|---|---|---|

| – Each layer of powder is spread thinly with a roller and sintered under a CO2 laser. Unprocessed powder layers will be returned to the material container used for the next printing. | – This 3D printing method does not require a support layer, so printing time is 5-10 times faster, post-printing post-processing is 5 times less, helping to reduce costs 7 times compared to other technologies. | – SLA technology with reusable materials such as: Nylon plastic powder, heat-resistant plastic powder, glass plastic powder, like ABS, foam plastic powder, ceramic plastic powder… These are all types of materials The material has special mechanical properties and is called a durable material used for functional parts and replacement parts. Along with metal materials, this is the material with the most similar mechanical properties to the original material. Excess material is reused for the next printing. | – Print functional parts and replacement parts for immediate use. Check the design and material in advance |

5. CJP – Printing Technology

Projet CJP 860 Pro Projet CJP 860 Pro |  Projet CJP 660 Pro Projet CJP 660 Pro |  Projet CJP 460 Plus / 360 / 260 Plus Projet CJP 460 Plus / 360 / 260 Plus |

Xem chi tiết các máy in 3d – Công nghệ in CJP tại: https://scantechvn.com/may-in-mau-3d-cjp

| PRINCIPLES OF OPERATION | FEATURES | MATERIALS | APPLICATIONS |

|---|---|---|---|

| – Use adhesive to bond each thin layer of dough together. The color layer will be sprayed on the outside like a coat. Can print any color, texture, or pattern. | Similar to SLS technology. – CJP technology does not need to print a support layer, so printing time is 5-10 times faster, post-printing post-processing is 5 times less, helping to reduce costs 7 times compared to other technologies. | – CJP uses hard mechanical powder materials combined with CMY or CMYK color cartridges and corresponding hardening solution sets. Excess material is reused for the next printing. | – Model designs: Marketing, sales, art display models. Printing models of shoes, buildings, architecture, miniature statues Simulation: Practice surgery, FEA analysis, testing, teaching. Print color and texture samples. |

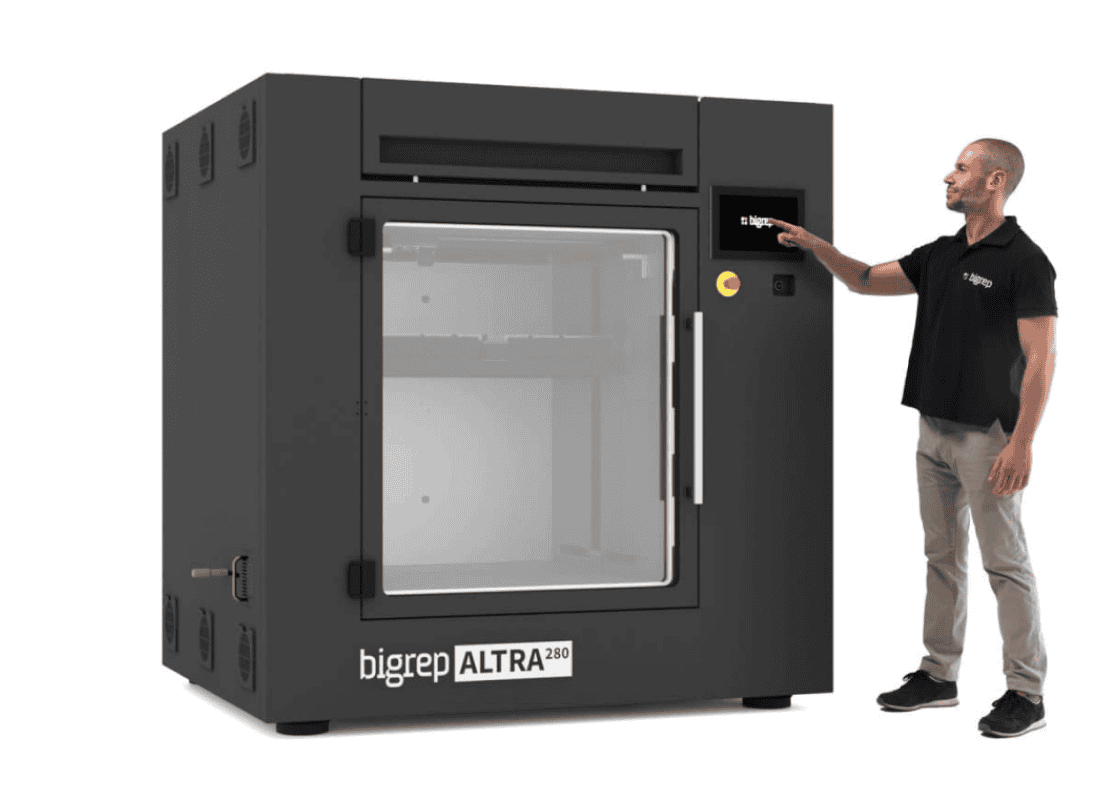

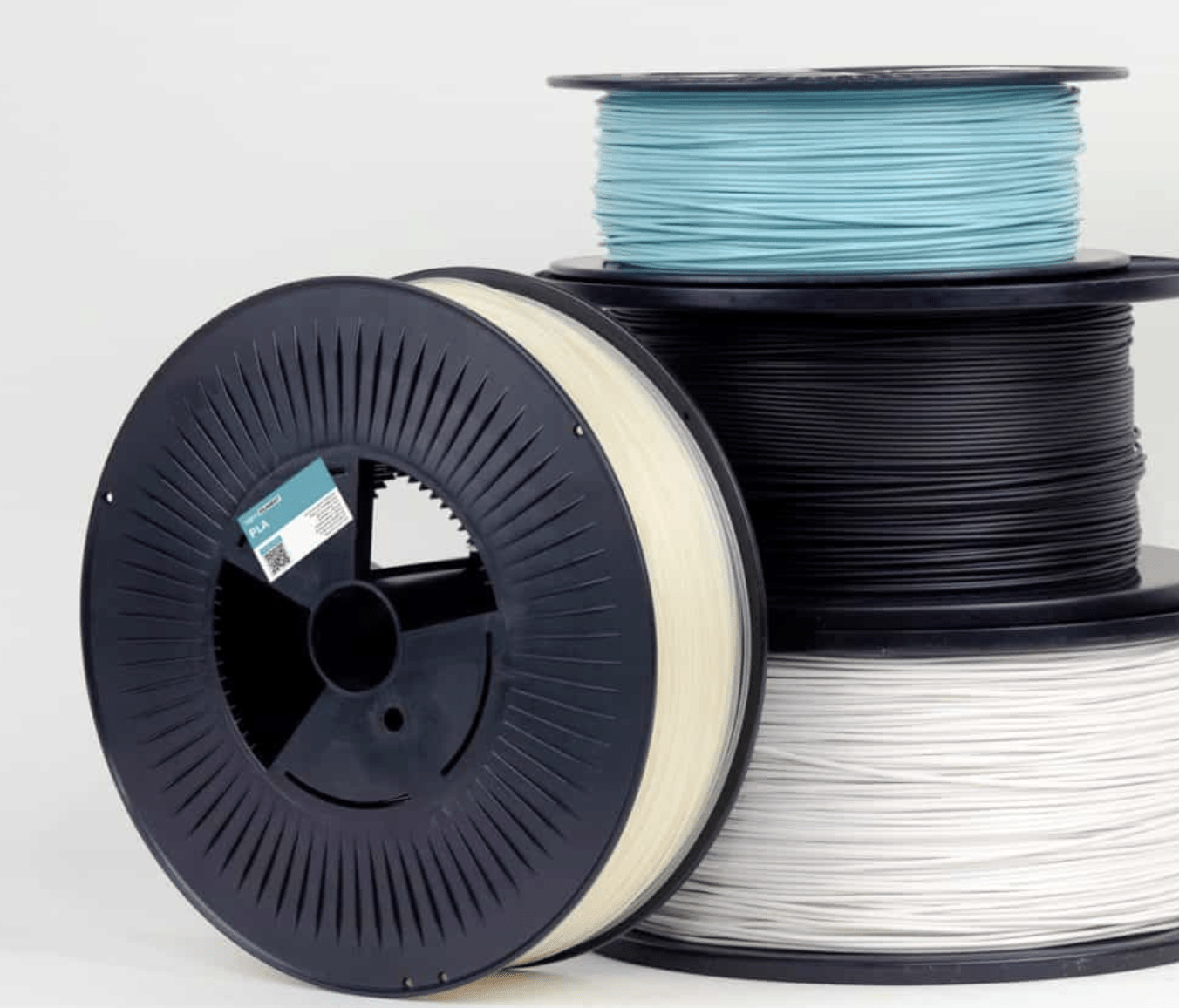

6. FDM ( FFF)

| PRINCIPLES OF OPERATION | FEATURES | MATERIALS | APPLICATIONS |

|---|---|---|---|

| – It is the most popular and cost-effective technology compared to all other 3d printing technologies. FDM uses heat to melt fibrous plastic materials and stack them layer by layer. Monochrome colors can be mixed. | – Simple, easy to use, low cost. Only print simple products to check shape and design without high precision or smooth surface. | ABS, PLA (all colors), Nylon, PC plastic rolls with mechanical properties of hardness, toughness, flexibility, and clarity. | – Printing models of architecture, art, fine arts, education Printing jigs, zigzags, simple molds |

RELATED PRODUCTS

CONTACT

- Login /

- Register

FDM Cube Pro

FDM Cube Pro