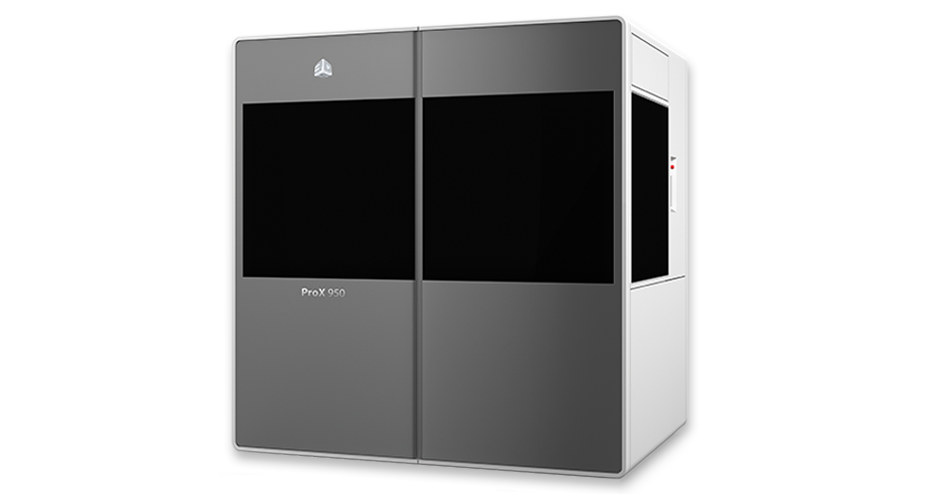

Metal Printing Machine – DMP 500 (Industrial scale production with large sizes)

Specifications

Tech

Direct Metal Printing (DMP)

Build volume (W x D x H):

500 x 500 x 500 mm(20.7 x 20.7 x 20.7 in) – height inclusive of build plate

Vacuum chamber

(O2< 25ppm)

Mô-đun

Quick-swap removable print modules

Two-dimensional dough

Fast two-dimensional powder deposition

Vật liệu thường dùng cho DMP 500 Factory

Product Description

Modularity for scalable factory solutions

The DMP Factory 500 includes modules with specific functions and is designed to maximize efficiency by optimizing usage. Each module in the factory solution is fully integrated with a Removable Print Module (RPM) that is vacuum-sealed for a controlled print environment and designed to be moved between modules. -boil the printer and powder to ensure a continuous production process.

Printer modules (PTMs) are designed to print parts continuously, 24/7. Powder Demolition Module (DPM) and Powder Recycling Module (PRM) are designed to efficiently depowder parts on build platforms and automatically recycle unused powder materials to prepare RPM for the next build. The DMP Build Switch Station (BCS) can be used to transfer print modules from one build to the next and can effectively serve two DMP Factory printers running different materials .

Configure your factory setup with the optimal number and type of modules you need to meet your production process needs.

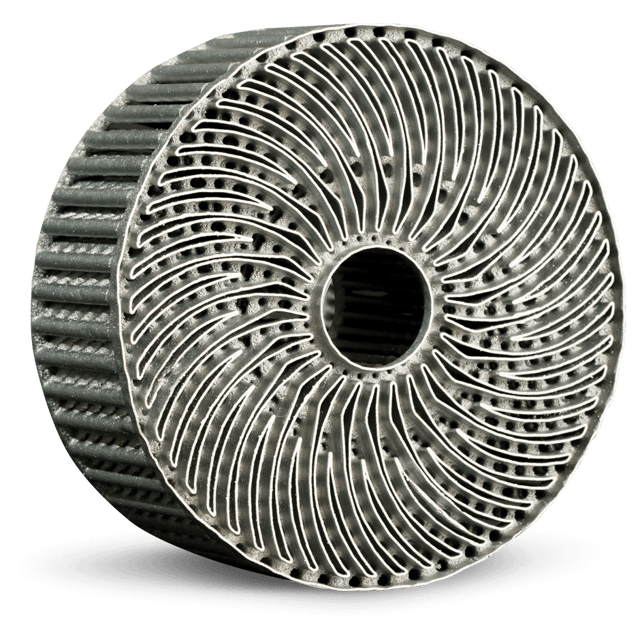

Large seamless parts

The DMP Factory 500’s intelligent laser configuration and 3DXpert software-driven scanning technology enable the seamless production of large parts up to the size of the entire build volume (500mm x 500mm x 500mm). This delivers the highest surface quality for metal 3D printed parts with superior material properties.

Consistent, repeatable quality

When it comes to manufacturing, repeatable part quality is essential. With a vacuum chamber to ensure the lowest O2 content, the DMP Factory 500 printer module delivers high-quality 3D printed metal parts. Powder degradation is eliminated by always keeping powder in an inert condition, whether you are printing, depowdering, recycling, or transporting between modules.

High productivity

With high print volumes (500 x 500 x 500 mm) and high throughput supported by multiple lasers, the DMP Factory 500 delivers high productivity in metal additive manufacturing. Combined with the modular design, scaling up production is simple through the installation of additional metal printers and powder modules.

Metal 3D printing with lower component costs

The modular design of the DMP Factory 500 enables the functionality of all metal 3D printing and continuous powder management modules to maximize uptime, throughput and operational value.

The ability to combine the number and type of modules needed for your production process helps optimize your investment while minimizing manual processes, further reducing ownership and operating costs .

Proven Metal AM technology

High-throughput, highly repeatable metal AM systems produce precision-quality parts from a variety of alloys with high-quality material management for maximum powder utilization. For companies scaling up metal AM production and requiring operators to limit powder exposure.

Optimize your workflow

Workflow optimization solution for massive scalability, repeatable high-quality parts, high throughput.

Flexible and cost-effective construction solutions

The DMP Build Switch Station is a self-contained module in which the DMP Factory 500 detachable print module with a completed build can be changed to a new build-ready state. The DMP Build conversion station allows users to discharge the powder for the finished build, remove the base plate with the printed part, add new powder, install the new base plate, and prepare the removable print module for ready-to-build. do the next job. Material changes on the DMP Build Change Station are performed in just a few minutes. As a result, it can serve multiple printers running different materials in parallel. The DMP Build Switch Station is ideally suited to launch production on our DMP Factory 500 solution, which can eventually be upgraded to our premium range of peripherals with modular Dedicated reduction and screening to meet increasing throughput demands.

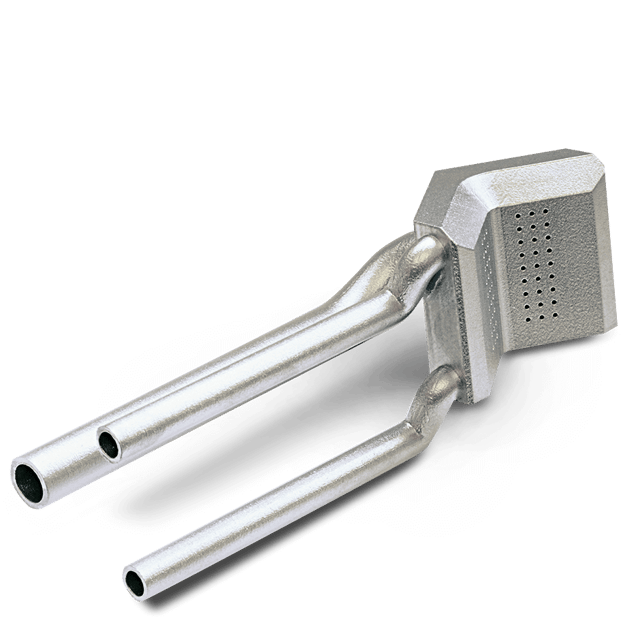

Reduced weight/lightweight design

Simplified assembly

Reduce the number of parts

suitable cooling

Enhance fluid flow

The right network

Optimize topology

Mass customization

RELATED PRODUCTS

CONTACT

- Login /

- Register