Titan EXT 1270

Specifications

Viên Titan EXT 1070

1270mm X x 1270mm Y x 1829mm Z (50”x50”x72”)

Đường kính vòi phun viên

0,6 mm - 9,0 mm

Chiều cao lớp viên

0,4 mm - 6,0 mm

Thông lượng máy đùn viên

0,45kg - 13,6kg* (1lb - 30lbs*) mỗi giờ

Tốc độ

18.000 vòng/phút (1,5 mã lực)

Product Description

LARGE FORMAT, HIGH SPEED INDUSTRIAL 3D PRINTER WITH CNC MILLING OPTION

The EXT 1270 Titan Pellet (formerly Titan Atlas 3.6), 3D Systems’ largest printer, is a flexible and reliable industrial additive manufacturing system designed to utilize thermoplastic pellet raw materials low cost.

Print Faster: The EXT 1270’s pellet extrusion technology prints up to 10 times faster than traditional filament extrusion 3D printing with deposition rates as high as 30lbs (13.6kg) per hour.

Reduce your costs: The use of pelletized feedstock means EXT 1270 can reduce feedstock costs by up to 10 times. Production requires no lighting and on-site milling options help cut labor costs.

Reliable production: With dimensions of 1270 mm x 1270 mm x 1829 mm (50″ x 50″ x 72″), the EXT 1270 can print most large parts in one piece without the need for gluing.

This large format 3D printer features a single pellet extruder as standard but can be customized with up to three tool heads, including a second pellet extruder, filament extruder and 3-axis milling spindle. The EXT 1270 is the ideal solution for large-scale parts production, from tooling and samples to end-use products.

Built for production

The EXT 1270 Titan Pellet is purpose-built for additive manufacturing, capable of producing high-performance, functional parts in industries such as foundries, automotive, aerospace and defense as well as consumer products.

With a welded steel frame and industrial actively heated housing, the EXT 1270 is production ready and can be upgraded with a second pellet extruder, filament printing capability and/or CNC milling functionality at the time of purchase or after that.

Whether you need samples, molds, tooling, jigs, fixtures, end-use parts or full-scale prototypes, the EXT 1270 is a proven manufacturing solution.

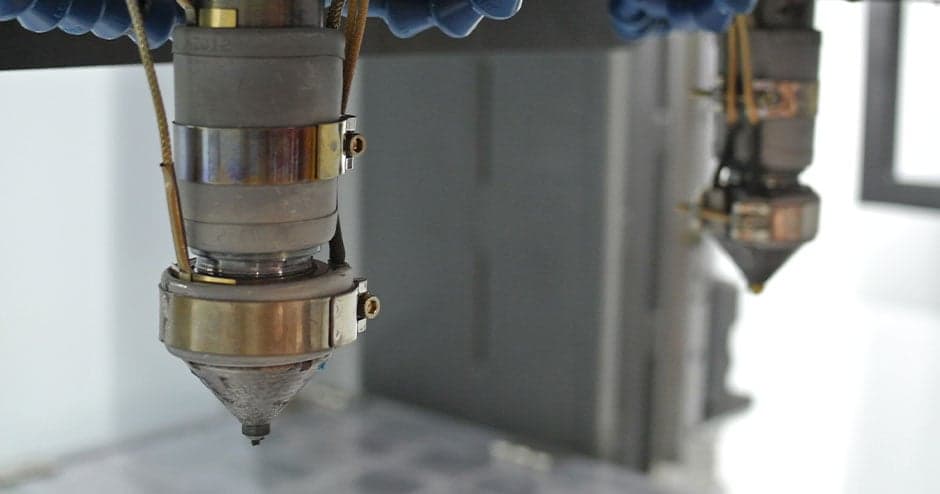

Pelletizing on EXT 1270

EXT 1270 is proven with a variety of pellet materials, from conventional raw materials to high-performance, high-temperature materials such as CF-PEI, GF-PEKK, Nylons and Polycarbonate. Pellet extrusion also allows the use of highly flexible elastomers and high-percentage carbon and glass-filled materials that are difficult or impossible to print from filament while reducing material costs. up to 10 times and delivers 10 times higher deposition rate.

Combined production on EXT 1270

The EXT 1270 Titan Pellet features our proven pellet extrusion system and can be equipped with additional tool heads on the same gantry, such as a filament extruder or a second pellet extruder, allowing for printing Multi-material, high speed. With an optional CNC spindle tool head, the EXT 1270 enables true hybrid manufacturing, allowing machining of 3D printed parts both during and after the printing process. Experience additive manufacturing at the next level with the EXT 1270, which shortens cycle times and produces smooth, precise end-use 3D printed parts.

Production Manufactured with EXT 1270

- Increased production reliability: The EXT 1270 Titan Pellet features an industrial motion control system, including a CNC controller, a closed-loop system with servo motors on all axes and remote monitoring capabilities, all Both help increase uptime and reliability.

- Built for production: Designed for the factory floor, the EXT 1270 is a production-proven additive manufacturing system with a precision machined welded steel frame. The industrial enclosure is actively heated and insulated, complete with interlocking door locks, making it ready for any production environment.

- Configurable to your needs: With an open architecture design, manufacturers can choose from hundreds of pellet materials on the open market for their application on the EXT 1270. Print parameters and grind can be dialed in to optimize serial production applications, giving you more control over the process. Choose the EXT 1270 for reliable, production-ready large-format 3D printing.

RELATED PRODUCTS

CONTACT

- Login /

- Register