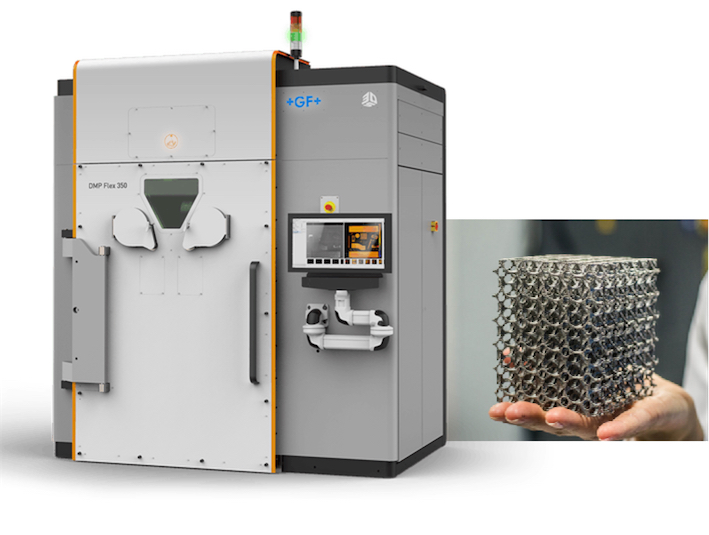

METAL 3D PRINTERDMP PLEX 350 – Powerful, flexible with 3 laser options

Specifications

Machine dimensions (W x D x H):

2370 x 2400 x 2869 mm

Weight

4200kg

Laser type

1 hoặc 2 hoặc 3 laser x 500 W / Laser sợi quang

Laser wave

1070nm

Print bed size

275 x 275 x 420 mm

Exact level

± 0,1-0,2% với tối thiểu ± 100 μm

Materials

LaserForm Ni718, LaserForm Ni615, LaserForm Ti Gr23, LaserForm Ti Gr5, LaserForm Ti Gr1, LaserForm AlSi10Mg, LaserForm AlSi7Mg0.6, LaserForm CoCrF75, LaserForm 316L, LaserForm 17-4PH, Thép LaserForm, AMPO M789, Vonfram, Nhôm A6061

Product Description

BENEFITS OF DMP 350 FLEX METAL PRINTER

- Metal 3D printing with lower component costs

- Reduced weight of components/Light weight design

- Reduce the number of parts / Optimize and simplify assembly details

- Optimize topologies/ Mass customization

- Repeatable, uniform quality throughout the construction area

- High productivity

- Print large seamless parts, functional parts, prototype parts.

- Proper cooling / Enhanced fluid flow

Flexible modularity for solutions to place the printer in the office or expand to a factory in the future.

|

FLEXIBLE: DETACHABLE PRINTING MODULE Improve machine flexibility and productivity with a Removable Print Module (RPM) and replacement with another (RPM). This positively impacts total investment costs as Customers can reduce downtime when changing media by having a dedicated RPM for each media. |

|

|

13 PRINTING MATERIALS AVAILABLE Ready-to-use metal alloy with thoroughly tested manufacturing parameters (Inconel, Titanium, Cobalt Chrome, Aluminum, Steel…). |

LARGE PRINT DESK SIZE Print large metal parts, reduce waste, higher production speed, short setup time |

|

O2 PURITY BELOW <25PPM DMP Flex 350’s unique vacuum chamber formulation significantly reduces argon gas consumption while exhibiting the best oxygen purity (<25 ppm). This results in exceptionally strong parts of high quality chemical purity. |

EXCLUSIVE SOFTWARE “ALL IN ONE” 3D XPRET® 3DXpert® is premium 3D Printing software exclusively for 3D Systems Customers. Each printed product is calculated, referenced, and built in an extremely intelligent and effective way. |

“The sealed vacuum chamber design not only maximizes powder reuse but also prevents argon gas bubbles from seeping into the part. When parts produced using this technology undergo hot pressing, the quality is comparable to that of forged parts. Such results are a must for aerospace components that frequently need to withstand high pressures.”

— Ronen Sharon, Sharon Tuvia-

EFFICIENCY DMP 350 FLEX BRINGS |

|

|

|

Increases stiffness to weight ratioTitanium brackets produced by DMP are 25% lighter than those produced by milling and have a better stiffness-to-weight ratio. |

|

|

|

|

|

Improved function optimization Combined with 3DXpert software, a multitude of scaffold structures are created, allowing for better osseointegration with orthopedic implants, for example. |

|

INCREASE CAPACITY 30% WITH DMP Flex 350 Dual & UP TO 50% DMP Flex 350 Triple

The DMP Flex 350 Triple is capable of printing seamless parts with maximum footprint and reducing build time by up to 30%. The DMP 350 Flex Triple maintains the high quality and repeatability of single and dual laser configurations while increasing productivity to reduce operating costs.

|

HOW HAVE THE DMP 350 SERIES BEEN DEVELOPED? More than 500,000 highly complex metal parts have been developed and continuously improved. With our advanced manufacturing centers, the DMP Flex 350 and DMP Flex 350 Dual have been developed and continuously improved through closed-loop feedback between the production team and the product development department. 3D System provides you with an integrated solution. Our DMP Flex 350 printer features patented technology, an extensively tested suite of advanced materials, 3DXpert metal additive manufacturing software and, last but not least, our expertise. our application engineers to realize time, cost and functionality benefits for customers. Our users rely on a reliable materials database for precise metal 3D printing without the challenging time and costly effort of developing process parameters themselves. Whether you choose a single laser or dual laser configuration, the high-performance metal additive manufacturing system is an efficient alternative to traditional metal manufacturing processes: With a build volume of 275 x 275 x 420 mm it offers reduced waste, higher production speeds, short setup times and very dense metal parts with excellent mechanical properties. |

RELATED PRODUCTS

CONTACT

- Login /

- Register