INDUSTRIAL 3D PRINTER & 3D PRINTING FACTORY LINE

Product portfolio

5 "INCREDIBLE" EFFECTS FROM 7 3D PRINTING TECHNOLOGIES:

- Create perfectly functional 3D Printed models, meeting all the most stringent international standards on: Material mechanical properties, accuracy level, printed layer smoothness and durability. difficulty of printing model.

- Shorten Design time, speed up innovation and New Product Development.

- Completely eliminate all costs for traditional mold prototyping.

- Save time, labor costs, risk costs.

- Huge competitive opportunity for businesses to prove their production capacity, improve quality and reduce product costs ???.

As part of 3D Systems' fully integrated and scalable FIGURE 4® STANDALONE technology platform, FIGURE 4® STANDALONE is a flexible and affordable solution.

Figure 4® Modular is a scalable, semi-automated 3D manufacturing solution that grows with your business, enabling capacity to meet your current and future needs, up to 10,000 parts per months, providing unprecedented production flexibility.

Figure 4® Production is a custom, integrated digital manufacturing solution with a workflow powered by 3D system software. Figure 4® Production prints up to 15 times faster than other 3D printing technologies* to support automation for high-volume production.

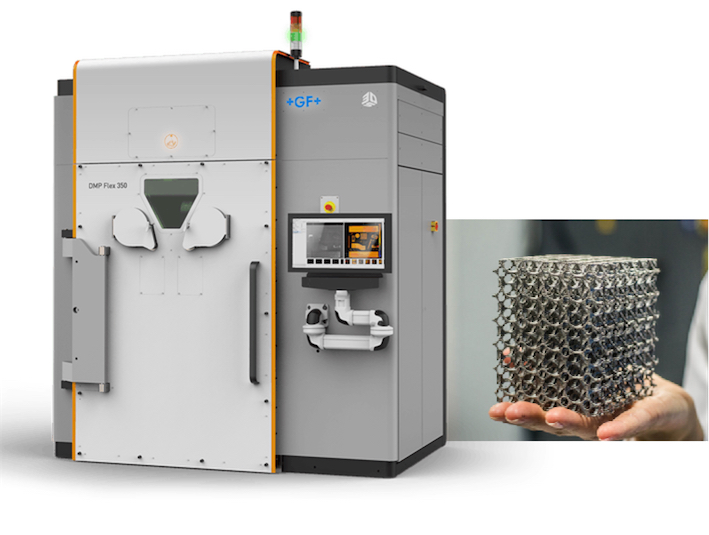

The DMP Flex 350 is designed for flexible application use for R&D projects, application development or mass production. However, it can be easily scaled up to produce parts in large quantities. Quick-swappable construction modules and fast powder recycling help speed up production.

The DMP Factory 500 includes modules with specific functions and is designed to maximize efficiency by optimizing usage. Each module in the factory solution is fully integrated with a Removable Print Module (RPM) that is vacuum-sealed for a controlled print environment and designed to be moved between modules. -boil the printer and powder to ensure a continuous production process.