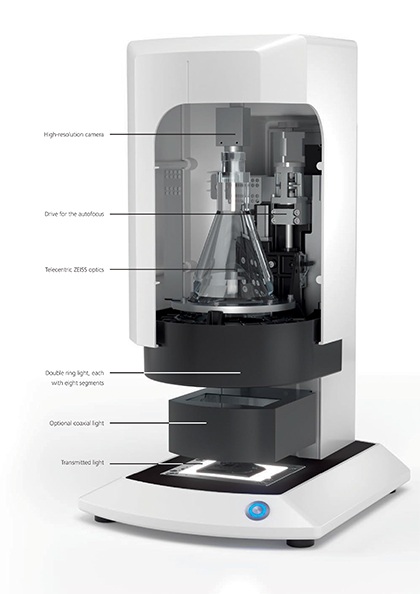

ZEISS O-SELECT

Specifications

Kích thước máy

402 mm x 510 mm x 727 mm (W x D x H)

Kích thước của trường đo

114 mm x 91.5 mm (không có bảng chuyển đổi),214 mm x 91.5 mm (có bảng chuyển đổi)

Thiết bị bao gồm

Máy chiếu đo lường kỹ thuật số, trạm làm việc, màn hình màn hình, phần mềm ZEISS NEO

Product Description

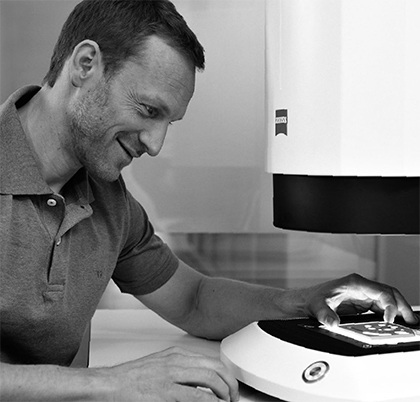

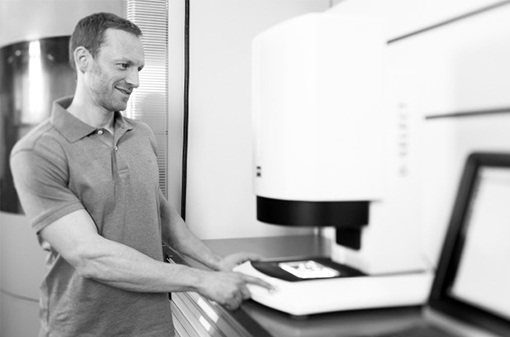

Accurate measurement at the touch of a button

| ZEISS O-SELECT Smart Digital Measurement Projector In production environments, coordinate measuring machines are increasingly replacing manual equipment. However, the operator’s impact with these manual tools should not be underestimated. With O-SELECT, ZEISS reduces this influence to a minimum. Thanks to the high level of automation and ease of use, complex measurements can be completed quickly, traceable and reproducible. https://www.youtube.com/embed/wiTTfwaPSS0 |

Accurate measurement at the touch of a button

By pressing a button.

The system locates and loads the appropriate program automatically.

Alignment, lighting and focus are automatic.

This not only reduces workload

of the operator, but also enables operator-independent and reproducible measurements.

Reliable results will be automatically exported or printed in a report.

| Fields of applicationWhether used in the automotive, electronics or plastics processing industries, ZEISS O-SELECT delivers exactly the results you need. The ZEISS O-SELECT digital measuring projector is particularly suitable for checking the dimensional accuracy of distances, radii or angles. Common experimental parts include punched and bent parts, or laser-cut and injection molded blanks. |

Auto focus

Inaccurate focusing can lead to measurement errors of several micrometers.

For devices on the market, this is not noticed by manufacturers.

To completely eliminate this source of error,

ZEISS O-SELECT automatically identifies the properties to be inspected and sets the focal plane in the most appropriate and precise way.

Automatically adjusts to the best light

Optical measurement can only be successful if the brightness of the light is correct.

To ensure that each feature is seen in the best possible light,

ZEISS O-SELECT offers a flexible lighting system.

Lighting is set automatically for each feature, eliminating any possibility of operating error

| .https://www.youtube.com/embed/RGEzkRMt7ME |

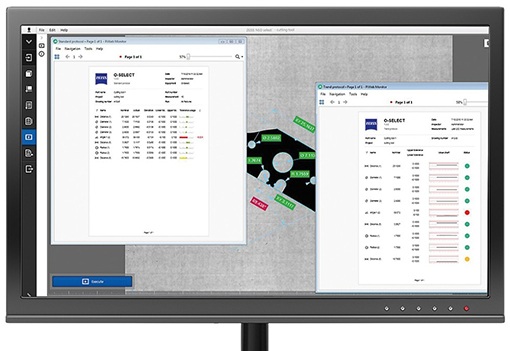

| Choose ZEISS NEO software ZEISS NEO software incorporates ZEISS measurement know-how designed to be simple, easy to understand, giving clear instructions – regardless of operator. This contributes to speeding up progress and reducing workload. |

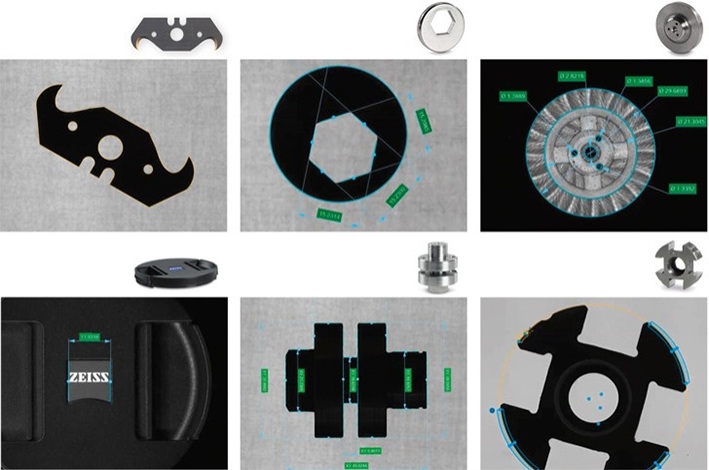

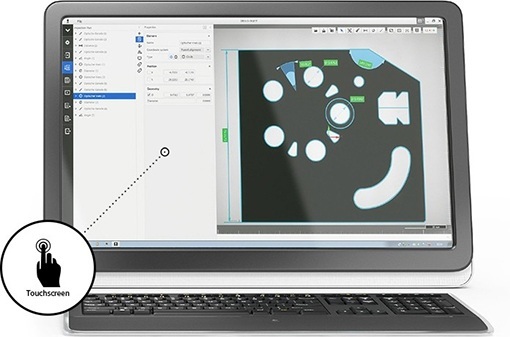

Measure directly from photo

With one mouse click – only what you asked for will be displayed.

For most measurements, you’ll never have to leave the main window.

Instead of navigating through sub-menus, you’ll measure directly in the image.

The software’s logical structure and clear graphics enhance the simplicity of measurements.

| Single measurements with Click & Pick Even for unknown parts that you do not plan to measure, you can easily measure quickly with the ZEISS O-SELECT using a high-contrast imager and autofocus, ZEISS NEO software will identify possible features such as circles and lines. When you move over one of these features with the mouse, you will get properties such as radius, distance and angle. With the first Click you define an initial feature, and with the second click you select one of the proposed experimental features. |

| Measure multiple details at the same time Take quick measurements of multiple parts simultaneously with ZEISS NEO software. Measure identical parts at the same time with just one button. Parts are automatically assigned numbers. After measuring, all saved “SnapViews” are available for selection, allowing you to see at a glance if properties are within tolerance. |

ZEISS O-SELECT can record and evaluate measurements using

ZEISS PiWeb reporting tool, integrated in the measurement software.

To enable effective information exchange, different report templates are available – from simple graphical reports to detailed reports.

This makes it possible for ZEISS O-SELECT to generate practical reports without requiring the user to have extensive knowledge.

Option

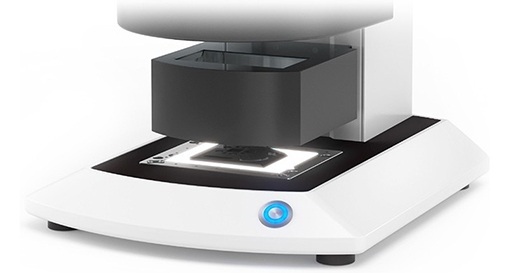

Easily expand the measuring range

The conversion table can be moved automatically and allows larger components to be measured.

Optional measuring field expansion allows reliable and fast measurements across the entire extended measuring field at the push of a button.

According to ISO 10360 standard.

Coaxial lamp

Coaxial lighting for optics is also available.

This is recommended for measuring deep structures that would otherwise be hidden by darkness.

| Size | 402 mm x 510 mm x 727 mm (W x D x H) |

| Size of the measurement field | 114 mm x 91.5 mm (without conversion board),214 mm x 91.5 mm (with conversion board) |

| Equipment included | Digital measurement projector, workstation, monitor screen, ZEISS NEO software |

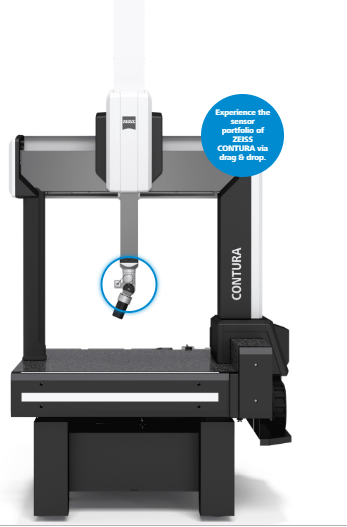

RELATED PRODUCTS

CONTACT

- Login /

- Register