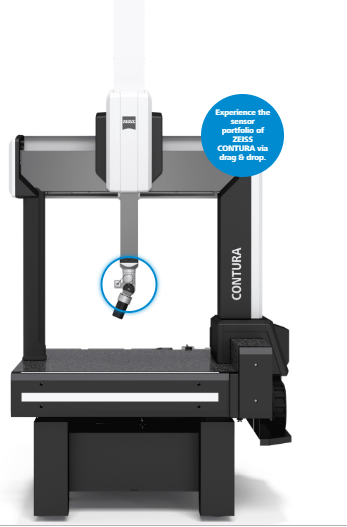

ZEISS CONTURA

Specifications

Phạm vi đo X x Y x Z [mm]

Sai số độ dài đo theo đo theo μm

900 x 1.200 - 1.600 x 800

1,2 + L / 350

1.200 x 1.800 - 4.200 x 1.000

1,9 + L / 300

600 x 2.400 - 4.200 x 1.000

2,9 + L / 300

1.600 x 2.400 - 4.200 x 1.500

3,5 + L / 300

2.000 x 2.400 - 4.200 x 1.000

3,3 + L / 300

2.000 x 2.400 - 4.200 x 1.500

3,9 + L / 30

Product Description

CONTURA – ZEISS guarantees absolute quality, reliability and flexibility. Latest generation of unprecedented precision, photosensitive accessories generation of large measurements. With superior scanning technology, complete conversion software makes ZEISS CONTURA a machine that affirms its leading position in the segment.

Measure E0 length error from 1.5 + L / 350 mm

Measuring range

| X | Y | Z | |

| 7/7/6 | 700 | 700 | 600 |

| 7/10/6 | 700 | 1,000 | 600 |

| 10/12/6 | 1,000 | 1,200 | 600 |

| 10/16/6 | 1,000 | 1,600 | 600 |

| 9/12/8 | 900 | 1,200 | 800 |

| 9/16/8 | 900 | 1,600 | 800 |

| 12/18/10 | 1,200 | 1,800 | 1,000 |

| 12/24/10 | 1,200 | 2,400 | 1,000 |

Diverse sensors

ZEISS CONTURA has a fixed sensor, a flexible RDS holder in the form of articulating probes , or scanning probes. Any sensor can scan. Standard pilot technology – for smooth operation without stopping.

Powerful and Precise

Depending on the setup, ceramic or CARAT guides are used for ZEISS CONTURA for high stability, low heat generation and minimal shifting weight. Lightweight ball bearings on all 3 axles ensure constant stability even during acceleration and acceleration. Calibration with crystal ceramic is gentle and does not require any temperature sensors or other detailed measurements. The device fits perfectly into the floor and is resistant to all impacts and other contamination.

CAA – Computer-like accuracy

The spherical shape is aimed at large impacts making it absolutely precise, especially during scanning. ZEISS CONTURA calculates every internal impact in detail. It ensures absolute accuracy even when scanning at high speeds

Convenient controls

The system is controlled via a user-friendly control panel and does not require another computer. Active manipulation ensures ease and precision in all directions of movements on the axes. Speed is set in CNC format

Condition

HTG (high temperature bias) gives a large temperature range (18-26 degrees) with constant parameters. Temperature sensors for parts and machines at x = 700/1,000 mm

Advanced sensor for maximum re-operation without the need for recalibration

The sensor is easy to change with active detection

The ZEISS air saving system allows saving up to 60% of compressed air flow

Sensor variations /SENSOR PARAMETERS

Direkt

The Direkt sensor model is ideal for measuring small devices, with right angles, without tilt angles. Equipped with the ZEISS VAST XXT sensor, ZEISS CONTURA direkt provides a specialized tool unique to the scanning world from ZEISS to produce, measure parts at a granular level, and segment work independently. The XDT single-point sensor by ZEISS can be additionally installed on the VAST XXT if required. Direkt ZEISS CONTURA is available in sizes 10/16/6

RDS

Combined with ZEISS’s VAST XXT, the flexible, articulating RDS allows measurements from all angles. With a total of 20,736 positions in 2.5 degree steps, RDS can scan to any angle. That is an absolute advantage for complex parts, for parts with complex profiles, or need to create complex profiles. Alignment time is minimized thanks to the optical alignment sequential mode. RDS is also capable of using other sensors from ZEISS on the ZEISS CONTURA.

AKTIV

ZEISS CONTURA aktiv follows standard scanning detection technology for fast scanning with a single movement. It can work with ZEISS’s VAST XTR yellow or VAST Both sensors share the same jack. Measurement program can be converted. A quick changeover QuickChange changeover system can also be fitted if required.

RELATED PRODUCTS

CONTACT

- Login /

- Register