T-SCAN HAWK 2 3D SCANNER

Product Description

T-SCAN HAWK 2 – “ALL IN ONE” HANDHELD, MOVING 3D SCANNING SOLUTION

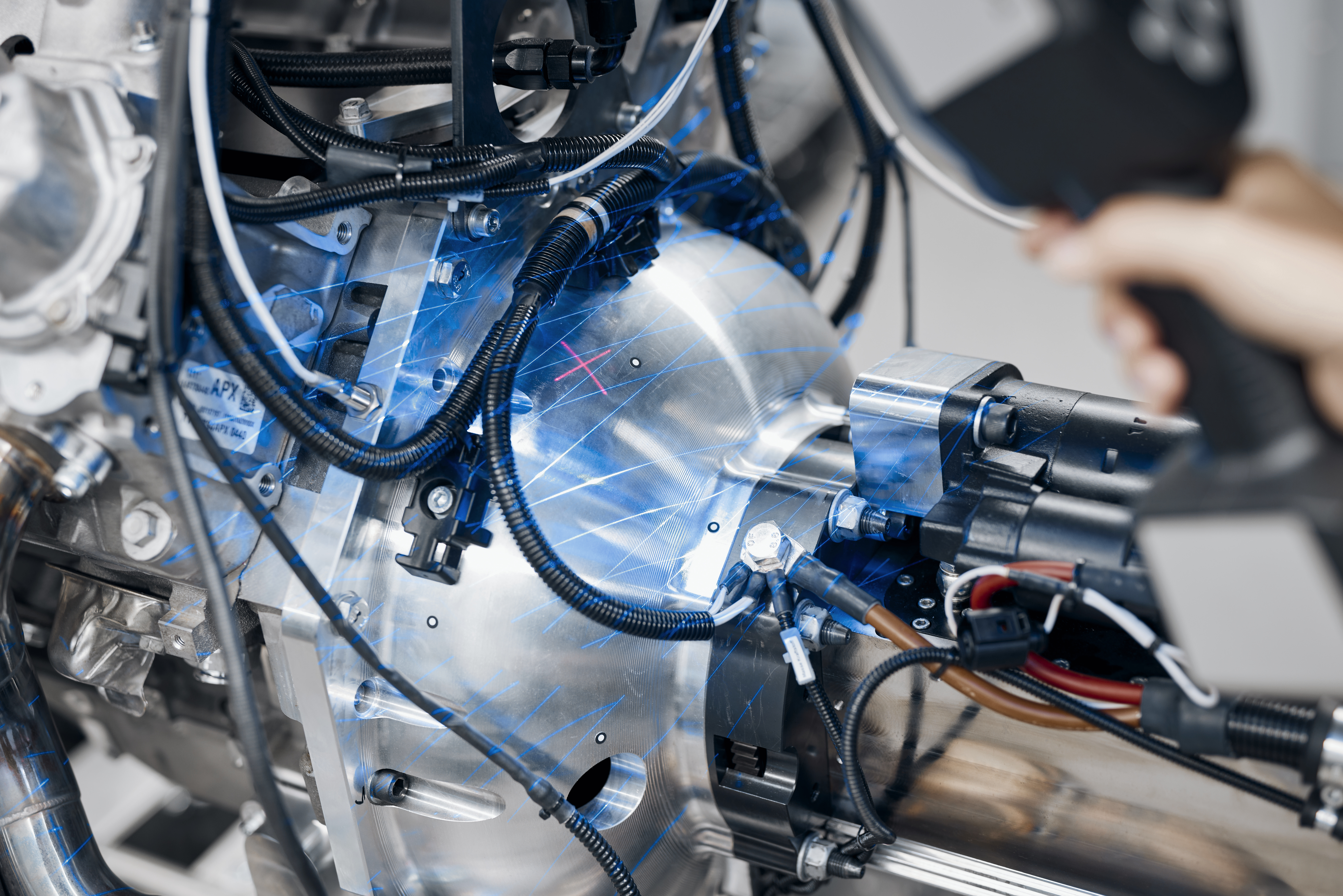

If in the past, with a limited investment budget, customers could only choose 1 of 2 separate specialized 3D Scanning devices: 1 to scan small sized products, 2 to measure large sized scans, now Carl Zeiss has brought a great alternative: the new T-SCAN HAWK 2: “ALL IN ONE”

| The new T-Scan Hawk 2 with “satellite” scanning mode meets all needs of 3D scanning with complex geometric profiles: From small details, deep grooves, bars to large and very large details without limits. size limit. From dark to shiny surfaces on all materials and in all environmental conditions and difficult terrain. | Outstanding compared to other mobile and semi-mobile handheld 3D scanners (robot arms) currently on the market, the new T-Scan Hawk 2 provides extremely high accuracy: up to 20 microns, Measure and scan at super fast speed, operate smoothly, quietly and stably. | The new T-Scan Hawk 2 is integrated with GOM software – software exclusively developed and optimized for every feature. | The new T-Scan Hawk 2 has been tested and certified for its optical measurement and calibration results by the international organizations ilac-MRA and DAkkS. |

LOW INITIAL COST – HIGH EFFICIENCY

A great invention with the new “satellite” scanning mode

The T-SCAN hawk 2 is the first handheld laser scanner with a “satellite” scanning mode that can scan very large volume objects without using integrated imaging with marked markers encode. No compromise on accuracy. Position the scanner easily with the new laser grid!

SCANTECH VIETNAM COMPANY

Address: BT6-30 Diplomatic Corps, Xuan Tao Ward, Bac Tu Liem District, Hanoi

Email: ktscantech@gmail.com

Hotline: 0862170366

Facebook: https://www.facebook.com/scantechvn

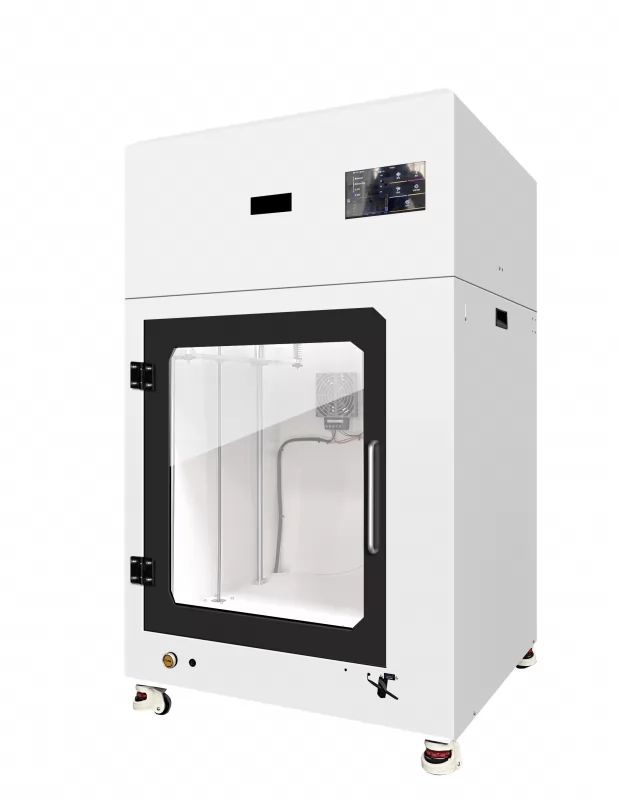

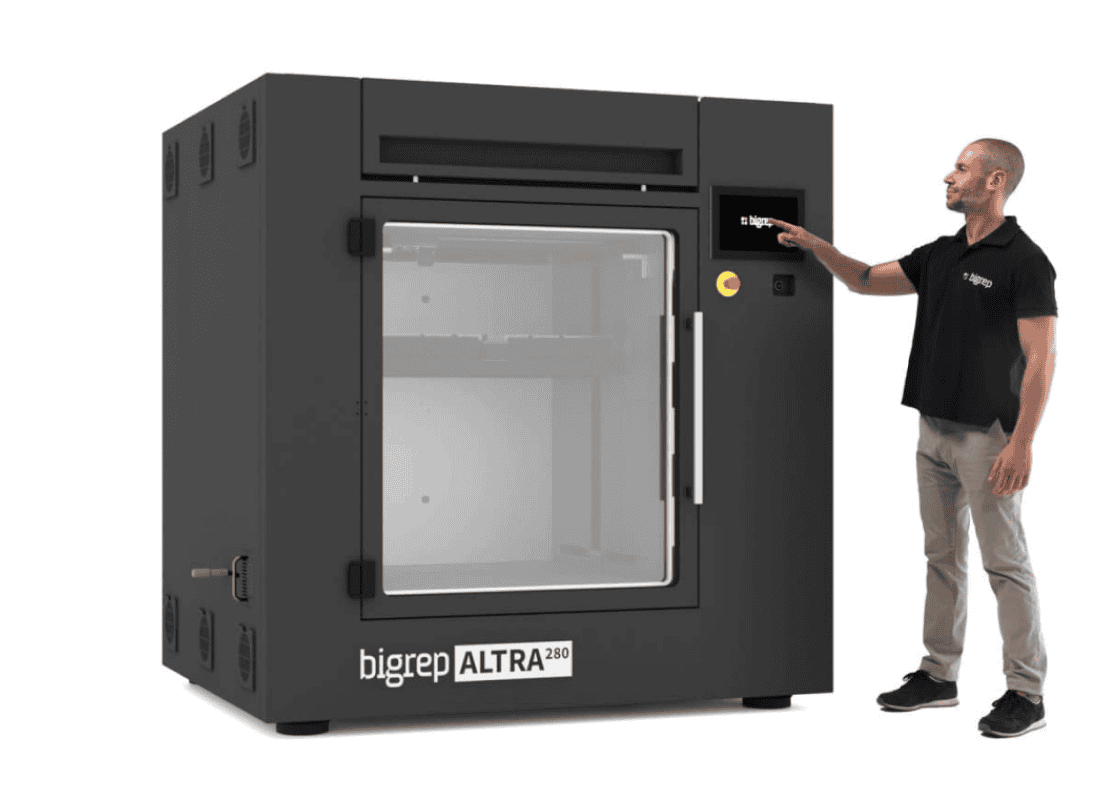

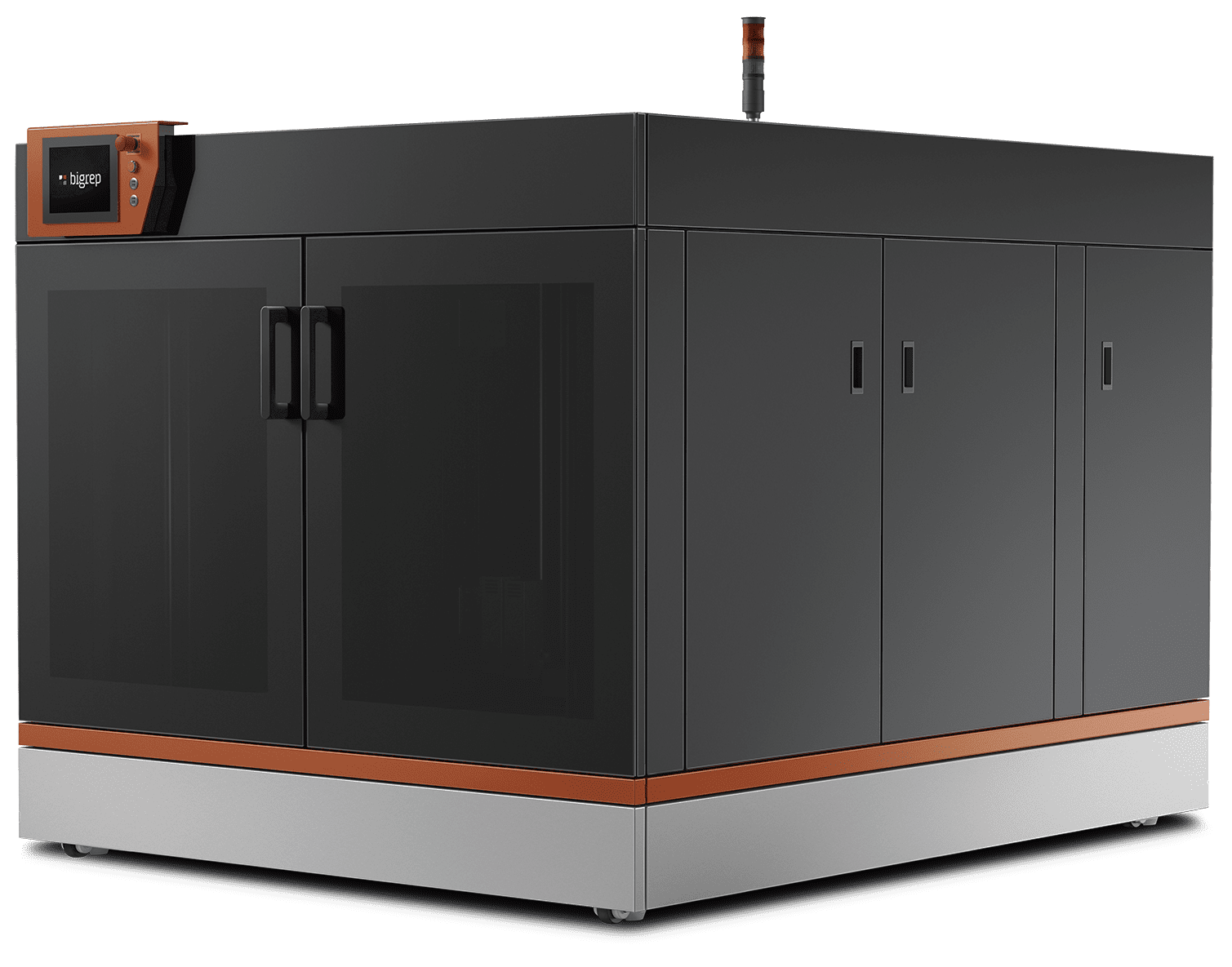

RELATED PRODUCTS

CONTACT

- Login /

- Register