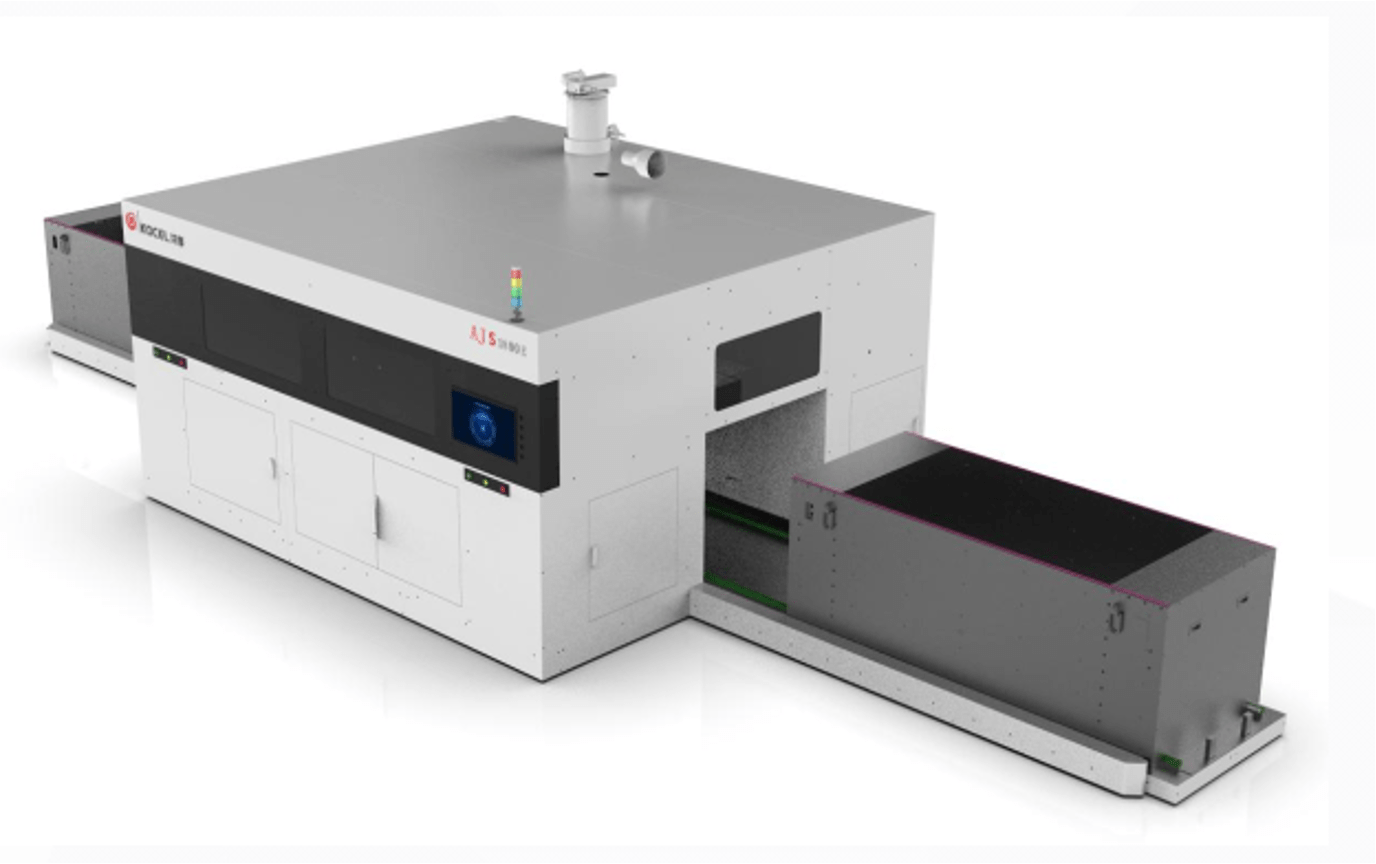

SLS 380

Specifications

Tech

SLS

Maximum build capacity (W x D x H)

15 x 13 x 18 in (381 x 330 x 460 mm)

Production speed

2,7 l/h

Ability

Streamlined production control, including 3D Sprint® integrated additive manufacturing software, fully automated powder handling, and optional 3D Connect capabilities

Feature

Automatic nesting of 3D parts

Product Description

PROCESS CONTROLLED, INDUSTRIAL-SCALE ADDITIVE MANUFACTURING SOLUTION FOR SELECTIVE LASER Sintering

Production-grade SLS workflow solution

The SLS 380 is a high-throughput SLS additive manufacturing solution with unprecedented levels of power, consistency, performance and productivity. Optimized for those who want to take the next step in integrating additive manufacturing into their factory ecosystem, 3D Systems’ SLS 380 and complementary software, material handling solutions and post-processing meet the need for cost-effective mass-produced parts.

| Highly productive, repeatable parts | 100,000 thermal data samples per second | Automatic material handling | Provide materials and add flexibility | Industrial-scale post-processing with AMT PostPro |

| The SLS 380 features closed-loop process controls that enable high levels of repeatability across multiple parts, builds, machines and locations. In addition to the new water-cooled laser, the system also uses algorithms. Custom developed 3D system to manage, monitor and control thermal uniformity in the print chamber in real time. | The algorithm manages eight individually calibrated heaters, along with an integrated high-resolution infrared camera that records more than 100,000 samples of thermal data from inside the fabrication chamber every second. This data along with infrared sensors will maintain temperature stability for every layer of part construction throughout the build process. With more consistent thermal uniformity throughout the entire fabrication process, manufacturers can now deliver more dimensionally consistent parts with better mechanical performance, higher repeatability and higher productivity – all with less human intervention and lower overall operating costs. | A key part of the SLS solution’s capabilities is the materials quality center (or MQC) to control, blend and supply materials on demand to achieve the optimal ratio of fresh to recycled powders. . There are two MQC options for SLS printers: MQC Single and MQC Flex. The MQC Single is designed to connect to one SLS printer, while the MQC Flex is optimized to deliver material to up to four printers at once, minimizing waste and eliminating operator intervention . MQC Flex automatically mixes fresh and recycled powders according to your specified mix ratio, and includes a recycled powder container for convenient and immediate storage of unused powders after printing. Both versions of the MQC feature fully automated material loading and an integrated breakout station for post-processing. | Allows multiple materials to be used on one printer. Quick material changes with minimal labor to maximize the value and expand the applications of SLS printers. Can be used with or without MQC module. Compatible with SLS 380 and select older printers. | 3D Systems has partnered with AMT to provide a fully automated post-processing process, from powder to air honing to deliver end-use parts faster and without consumables or operating costs hidden from other technologies. Production-grade nylon materials, advanced software processes and new selective laser sintering technology combine to create a highly efficient solution for direct 3D manufacturing. The SLS 380 delivers best-in-class part quality, fast build times, automated manufacturing tools, and lower total operating costs than similar printers. |

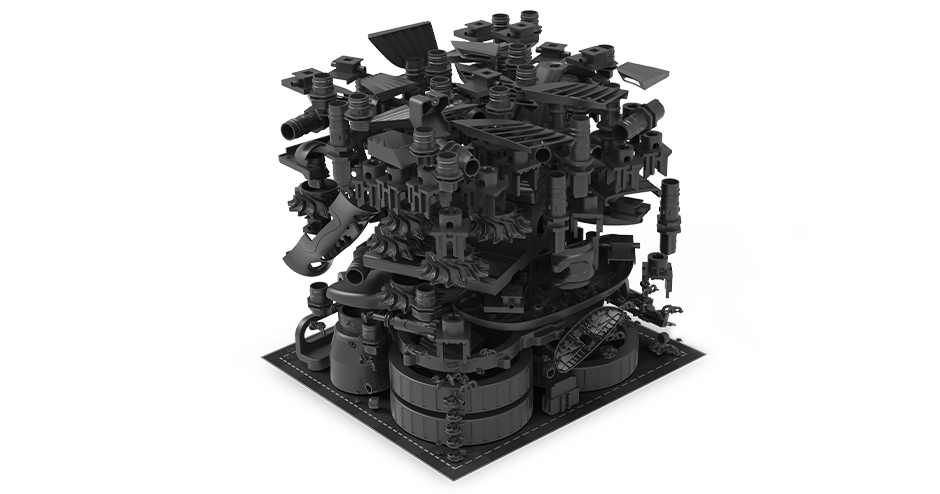

SLS material delivery module

RELATED PRODUCTS

CONTACT

- Login /

- Register