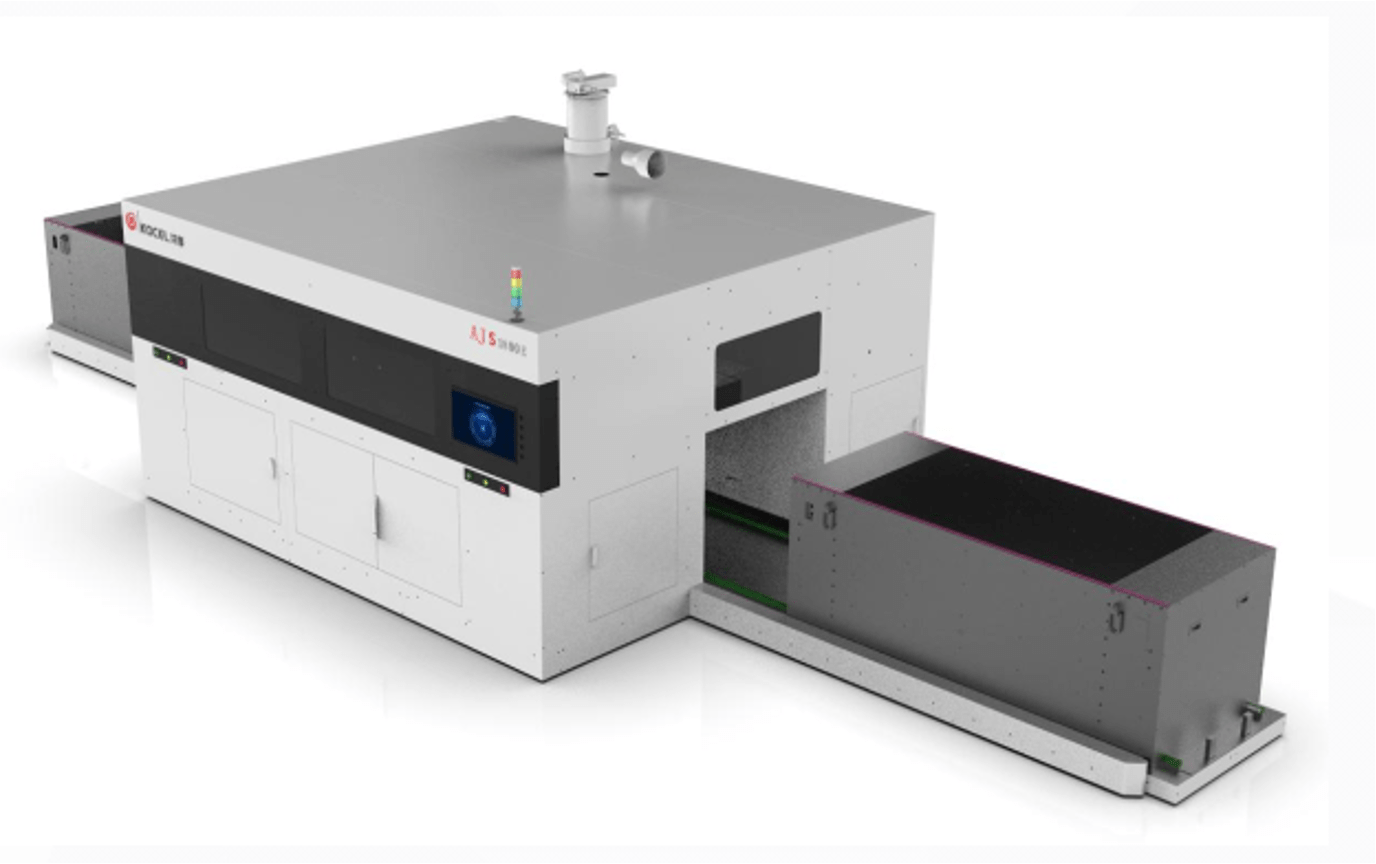

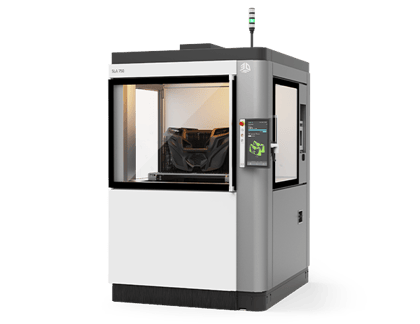

SLA 750

Specifications

Tech

SLA

Maximum build capacity (W x D x H)

29.5 x 29.5 x 21.65 in (750 x 750 x 550mm)

Dynamic beam range

0,125 - 1 mm

Maximum resolution

2000 dpi

Advantage

High laser power (4 watts) Dynamic beam range with 2 beam sizes per layer Choose from single or dual laser scanning Field upgrade possible from single laser SLA 750 to dual laser SLA 750 All-metal frame design, improves ergonomics and cleanability. The build volume is 15% larger and the hardware footprint is smaller than previous models Dual-rail, self-calibrating recoater Best production grade plastic material All new UX and UI with full visibility and user-friendly experience Remote monitoring and control The barrel is removable and mixes ingredients automatically in the barrel Automation is ready for factory-level ecosystem integration

Product Description

HIGH-SPEED 3D Stereoscopic Printing SOLUTIONS FOR PRODUCT MANUFACTURING

Production-grade SLA workflow solution

The SLA 750 delivers breakthroughs in productivity, speed, reliability and automation from the leading innovator in stereolithography (SLA) 3D printing. A full solution includes the SLA 750 family of large-format 3D printing systems, advanced manufacturing-grade photopolymer materials, PostCure 1050 post-processing systems and the comprehensive, cloud-based manufacturing operations system Oqton.

Produce large parts at high speed

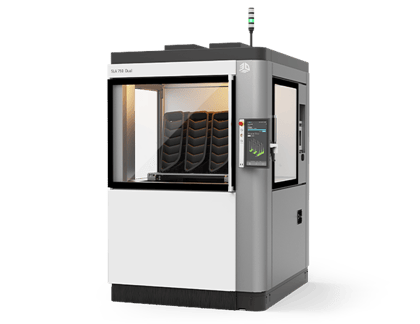

From the inventor of SLA and leader in innovation in production-grade photopolymer technology, 3D Systems introduces the fastest SLA 3D printers in the industry: the SLA 750 and SLA 750 Dual.

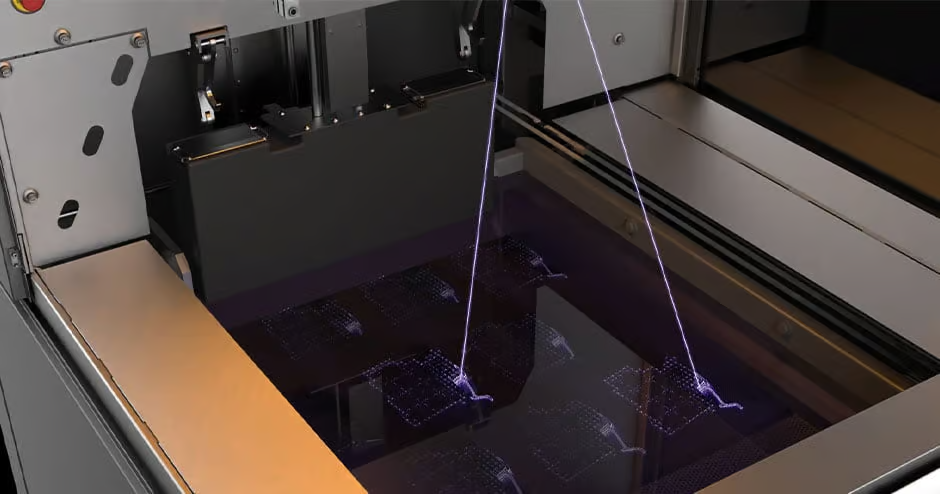

The SLA 750 Dual is the world’s first synchronous dual laser SLA printer that delivers double and triple the speed of current SLA printers, using a dual imaging system along with a proprietary scanning algorithm, vector technology Hyper-Scan™, specifically developed for efficient, high-quality production.

The single laser SLA 750 can be upgraded in the field to the dual laser SLA 750, allowing you to quickly scale productivity with increasing demand.

Mass production of car vents, each measuring 542 x 156 x 197 mm (21.3 x 6.1 x 7.8 in).

Laser scanning technology is optimized

Unlike conventional SLA 3D printers that use off-the-shelf scanning technology, the SLA 750 and SLA 750 Dual use a proprietary scanning algorithm developed for the unique needs of 3D printing. Hyper-Scan™ vector technology optimizes key factors in speed and productivity to meet the high demands of production applications and environments.

3D Systems’ SuperScan vector technology was developed specifically for the unique needs of additive manufacturing.

Ready to automate the fleet with 24/7 lights-out operation

The SLA 750 and SLA 750 Dual feature downstream automation readiness and robot compatibility for 24/7 lights-out operations, including fully automated printer turnover with offloading, washing and enter the print command. Both 3D printers have robot-accessible chamber handles, fixed START and STOP buttons, robot cycle start controller similar to existing CNC machines, connection port and automatic filling of bulk materials or bottles.

The SLA 750 enables 24/7 automated operation with full downstream automation readiness and robot compatibility.

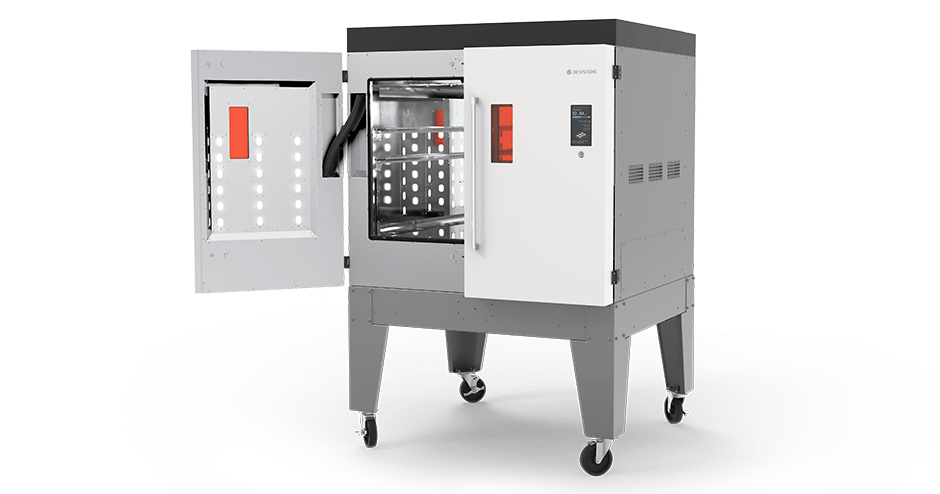

Industrial-scale post-processing with PostCure™ 1050

The PostCure 1050 is an industrial-scale post-processing system with 10 times the capacity of current systems, including high-speed, high-volume drying and curing for batch jobs and other applications. Large parts up to 1050 x 750 x 600mm. With optimized light wavelengths, individually configurable UV intensities and actively cooled LEDs with individually adjustable heating, the printed product is optimally processed, Does not warp due to heat.

PostCure 1050 delivers a 5x improvement in drying and curing speeds as well as 360˚ light uniformity for exceptional uniformity.

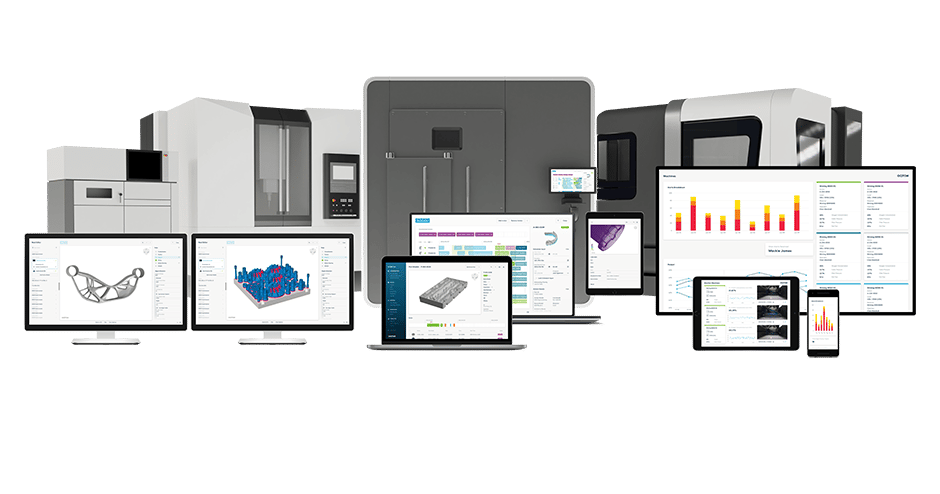

Integrate, manage and control the factory floor

The SLA 750 uses Oqton’s best-in-class cloud-based, AI-powered Manufacturing Operating System that unifies engineering and manufacturing through IoT and machine learning to solve manufacturing challenges in branch. Oqton’s Manufacturing Operating System seamlessly integrates additive manufacturing with your factory floor equipment and allows you to schedule production and post-production processes for efficient machine utilization, as well as Connect machines to enable full traceability and valuable data insights.

Connect all devices into a single ecosystem with Oqton cloud software.

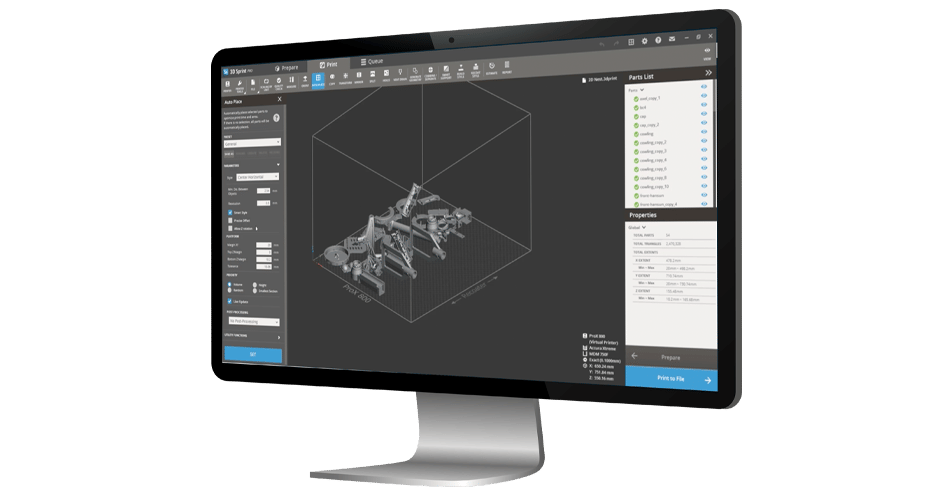

Terminal file to Printing Software

The SLA 750 uses 3D Sprint, an advanced single interface software for preparing, editing, printing and managing files. Go from design to high-quality, true-to-CAD parts quickly and efficiently without the need for additional third-party software. 3D Sprint is optimized for production environments saving time, UI and UX to maximize printer throughput and build volume utilization for batch jobs.

3D Sprint provides all the tools needed to go from design to high-quality, CAD-like parts without the need for third-party software.

New standards for SLA throughput, quality and production capacity

SLA 750 delivers outstanding surface quality and accuracy at every point on large builds, with outstanding detail resolution, wall smoothness and gradation fidelity.

Production-grade photopolymer materials, advanced software workflows combined with optimized laser scanning technology, deliver a high-throughput, automation-capable solution for production SLAs.

RELATED PRODUCTS

CONTACT

- Login /

- Register