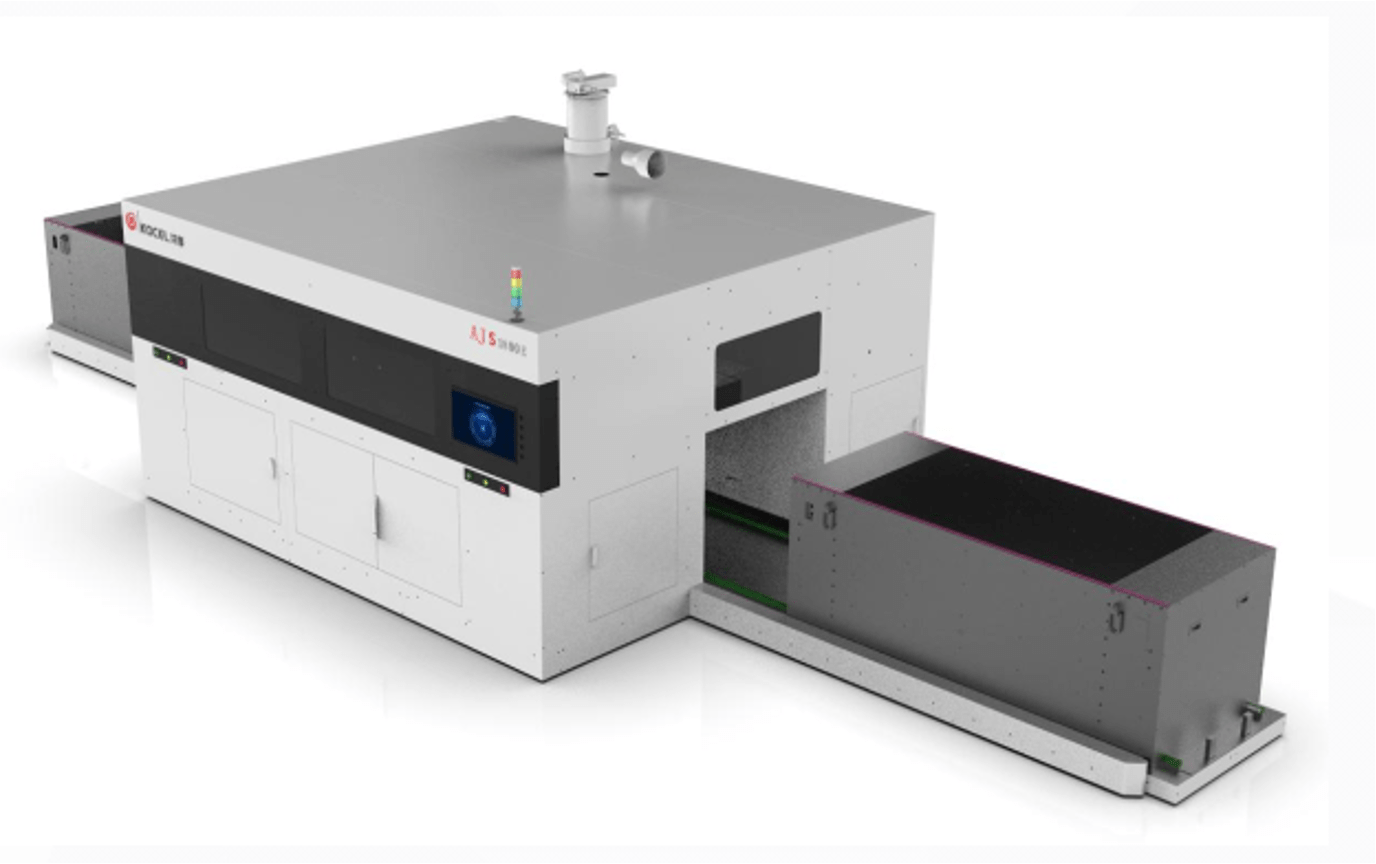

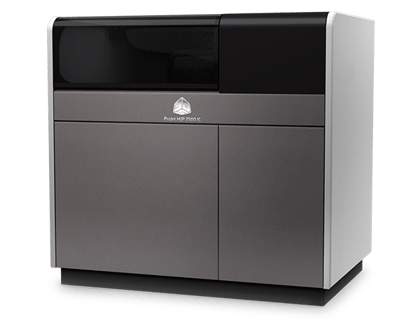

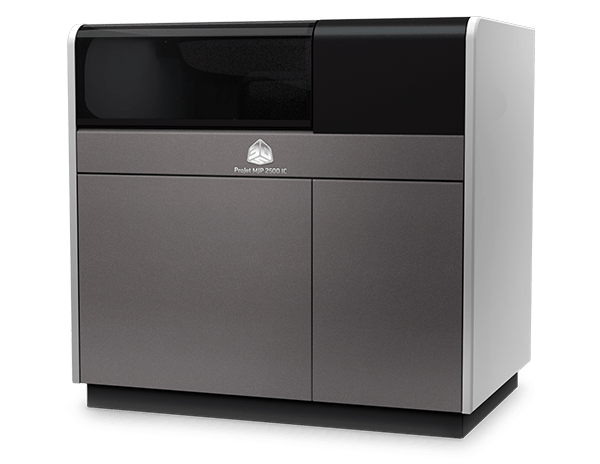

ProJet MJP 2500 IC

Specifications

Chế độ in:

MultiJet (MJP)

Khối lượng xây dựng: lên tới (W x D x H):

11,6 x 8,3 x 5,6 in (294 x 211 x 144 mm)

Tốc độ in

12,5 inch3 /giờ (205 cm3 /giờ)

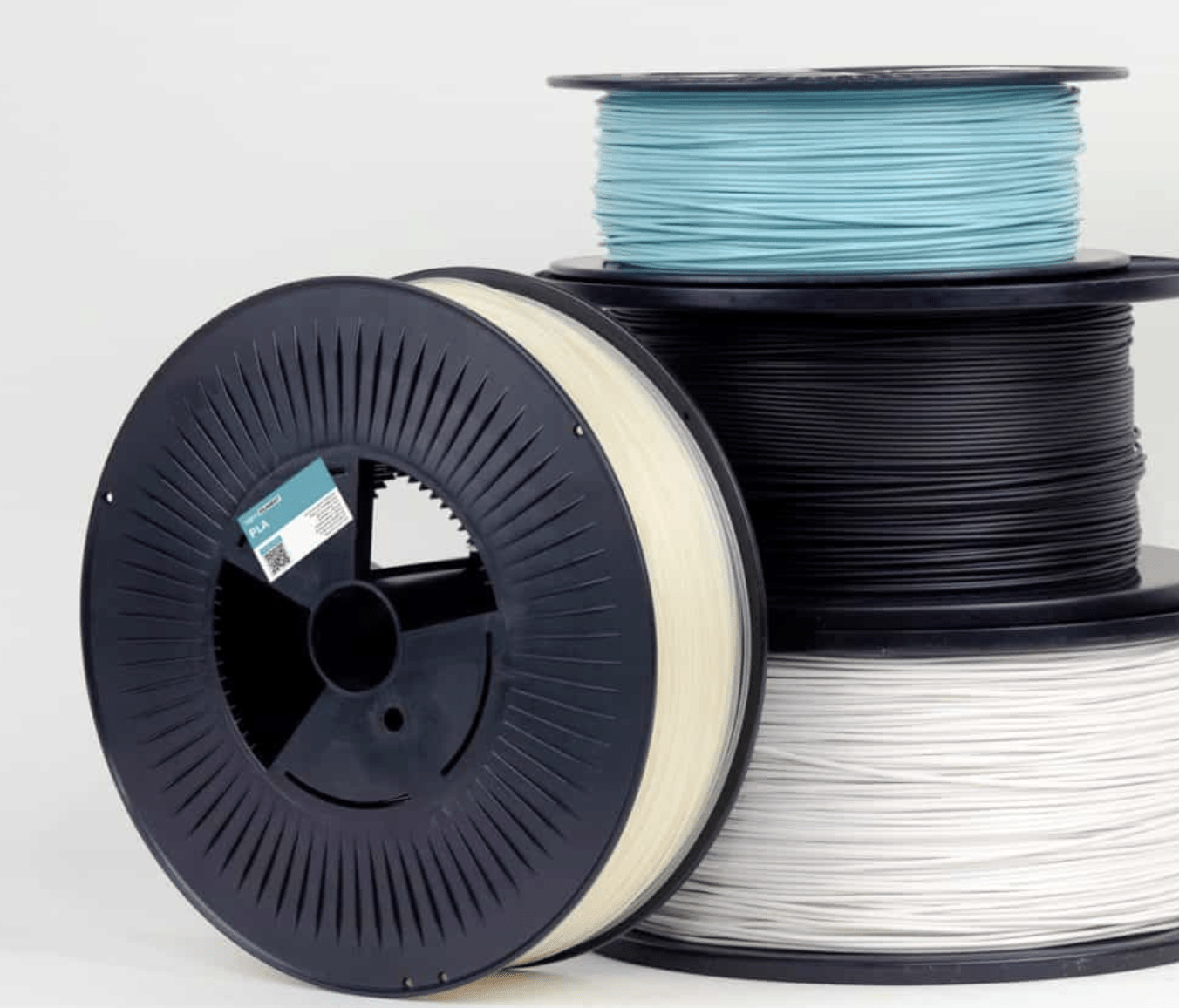

Nguyên liệu

Chất liệu sáp 100% VisiJet M2 Icast

Product Description

TOOL-FREE PRODUCTION WITH 100% WAX CAST MODELS

Unprecedented fast turnaround time

Save weeks on wax sample production with tool-free RealWax™ MultiJet Printing and accelerate time to market. The ProJet® MJP 2500 IC enables digital workflows with direct wax pattern printing, increasing productivity and enabling rapid product dispensing to provide superior customer service . With fast wax prototyping, short cycle times and 24/7 operation, you can count on the ProJet MJP 2500 IC output and improved foundry room efficiency.

Save weeks on wax sample production with the ProJet MJP 2500 IC

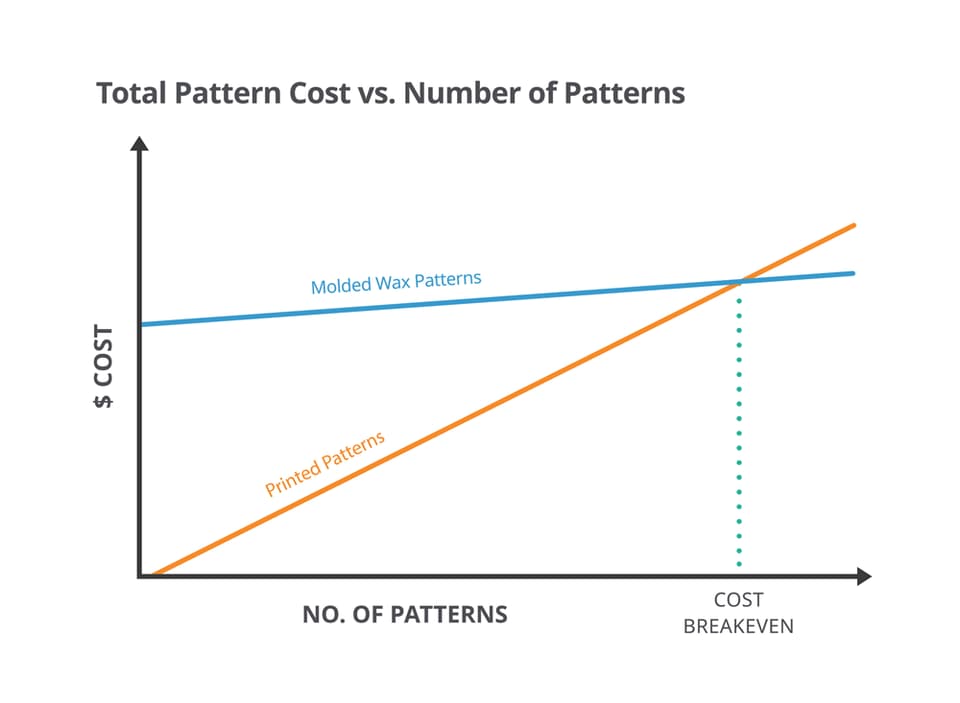

For a fraction of the tooling cost

Having hundreds of small to mid-sized samples on hand is faster and less expensive than the time and cost of building and running a traditional insertion tool. If design changes are needed, the benefits will multiply. The ProJet MJP 2500 IC takes advantage of existing flow casting processes and equipment. Expect fast depreciation and high return on investment with this unique industrial wax pattern 3D printing solution.

Hundreds of models are available at a fraction of the tooling cost

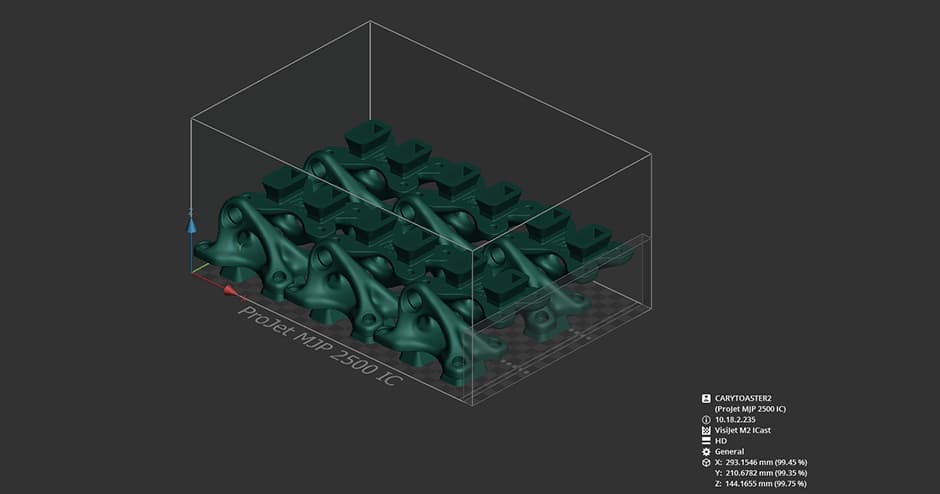

Ultimate design freedom

With digital design, you can create wax patterns for parts that take advantage of topology optimization, lightening, and part consolidation. The ProJet MJP 2500 IC allows you to create multiple parts with complex shapes or design variations simultaneously, while delivering better performing, more cost-effective components over time. compared to traditional alternatives.

Deliver better performing, more cost-effective components with topology optimization and part consolidation.

Best casting reliability

VisiJet® M2 Icast 100% Wax Material simulates the melt and burn characteristics of standard wax casting. This RealWax 3D printing material is seamlessly applied to existing wax casting processes. MultiJet Print patterns have tight tolerances, making them ideal for manufacturing complex precision metal components with reduced or no finishing work.

- High fidelity and repeatability

- Smooth surface

- Sharp edges

- Extremely delicate details

VisiJet M2 Icast RealWax material is applied seamlessly into existing wax casting processes

Resources are optimized

Streamline your file-to-model workflow with 3D Sprint® software that enhances the ability to prepare and manage additive manufacturing, unattended high-speed printing, and post-processing methods identified and controlled. MultiJet Printing’s reliable and easy-to-use process ensures performance, productivity and reliable results.

Comprehensive software solution for the MultiJet printing process

Agile manufacturing

MultiJet Printing offers greater versatility and flexibility to grow your business with an efficient solution for wax pattern production. Create, iterate, produce and refine on demand with just-in-time prototyping.

Digital foundry with Invest Cast and IC ProJet MJP 2500

Industrial casting

Cut weeks of production on your investment castings with tool-free 3D printed castings

Wax casting model measured in hours

Ideal for custom metal components, bridge manufacturing, and low-volume production, the ProJet MJP 2500 IC produces hundreds of 100% wax casting patterns at a fraction of the cost and time. compared to traditional wax pattern production. Offering design freedom, quality and repeatability, RealWax patterns are seamlessly introduced into existing investment casting processes.

RELATED PRODUCTS

CONTACT

- Login /

- Register