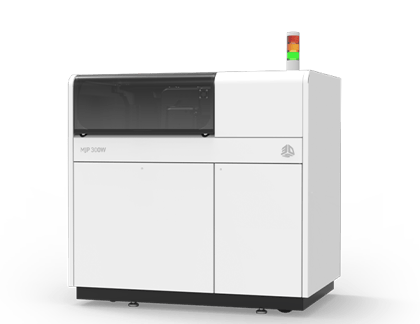

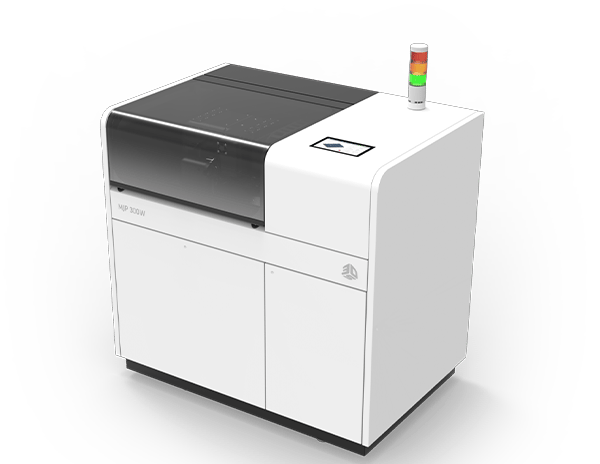

MJP 300W

Specifications

Print mode

MultiJet (MJP)

Construction volume: up to (W x D x H):

294 x 211 x 144 mm (11,6 x 8,3 x 5,6 in)

Software

3D Sprint

Material

100% wax metal casting template for use with standard processes

Product Description

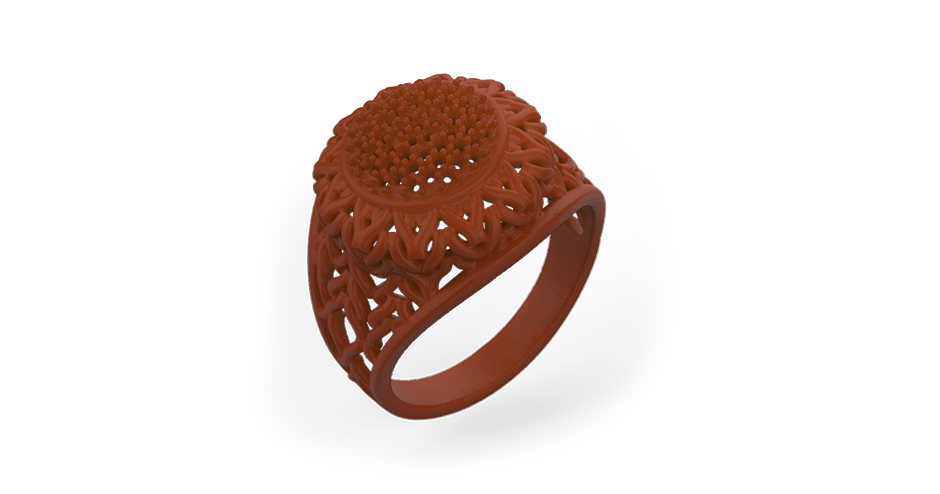

FLEXIBLE, FAST AND HIGH QUALITY 3D PRINTER OF JEWELRY WAX MODELS

Casting quality

MJP 300W uses 100% VisiJet ® wax material to create high-quality jewelry pieces that are flexible and durable. These materials are designed to ensure reliable performance and consistent results when used with existing lost wax casting processes and equipment.

VisiJet wax material melts like standard casting wax, creating defect-free castings with zero ash content. They are highly durable, making them ideal for processing and molding complex features. Additionally, high-contrast colors make it easy to visualize fine details.

The extensive print mode options on the MJP 300W 3D printer optimize quality for a variety of design styles and jewelry types, including improved surface quality.

Accurate and repeatable production of beautiful jewelry in virtually any metal without the need for a wax casting process.

High productivity

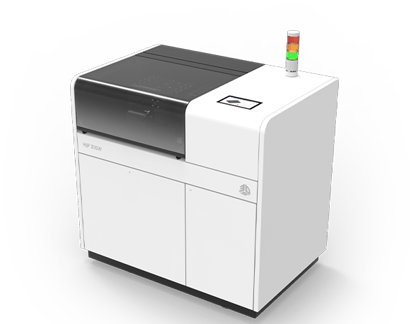

The MJP 300W 3D printer adapts your production process with greater flexibility, efficiency and quality in jewelry casting production. Choose from four print modes to match the level of speed, geometric complexity and surface quality your design requires. It enables high-volume production or rapid single-lane printing at fast print speeds, which improves foundry room efficiency. With large printing capacity and 24/7 operation, this next generation wax 3D printer ensures high productivity, resulting in fast depreciation and high return on investment.

Optimize your file-to-model workflow with the advanced capabilities of 3D Sprint® software. Benefit from the printer’s fast and flexible MJP print speeds, along with batch removal support, to create high-quality, prefabricated jewelry pieces.

Choose the ideal print mode to maximize productivity for a variety of jewelry styles and types.

Optimize speed, surface quality, precision and fine detail with four unique print modes.

High resolution sample

Create jewelry models with precise, razor-sharp edges and exceptionally sharp details that faithfully replicate original CAD designs. The MJP 300W’s superior resolution, along with its dissolvable and meltable mounts, ensures excellent surface quality, resulting in a reduced need for costly finishing labor, costly precious metal polishing and allows greater design freedom where geometry makes the surface inaccessible for polishing. These fine wax patterns are printed directly, eliminating the time, cost and geometry constraints associated with traditional tooling.

Maximum design freedom for bulk and mass production of custom jewelry.

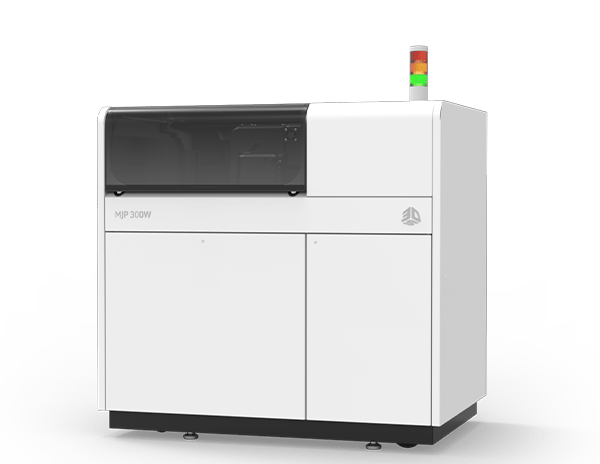

Produce highly productive pure wax jewelry models for lost wax casting

Get high-quality, precise jewelry casting models with the MJP 300W 3D printer. This 100% wax printer adapts to your workflow, delivering several short runs each day or larger prints the next day with fast print speeds and large print capacity. This printer is perfect for high-volume production of high-end jewelry castings with unique productivity, efficiency, quality and design freedom.

Applications

- Mass production of jewelry metal products

- Production of metal jewelry upon request

Benefits

- Extensive printing modes to optimize surface quality and productivity

- Get more samples faster to keep up with your metal casting process

- High-fidelity models you can rely on, including fine detail definition and sharp edges

- Greater geometric freedom with effective support removal

- High performance durable casting wax

- Low total cost of ownership (TCO).

RELATED PRODUCTS

CONTACT

- Login /

- Register