COLOR 3D PRINTER – CJP(Printed exactly according to actual colors)

3D PRINTING SAMPLES

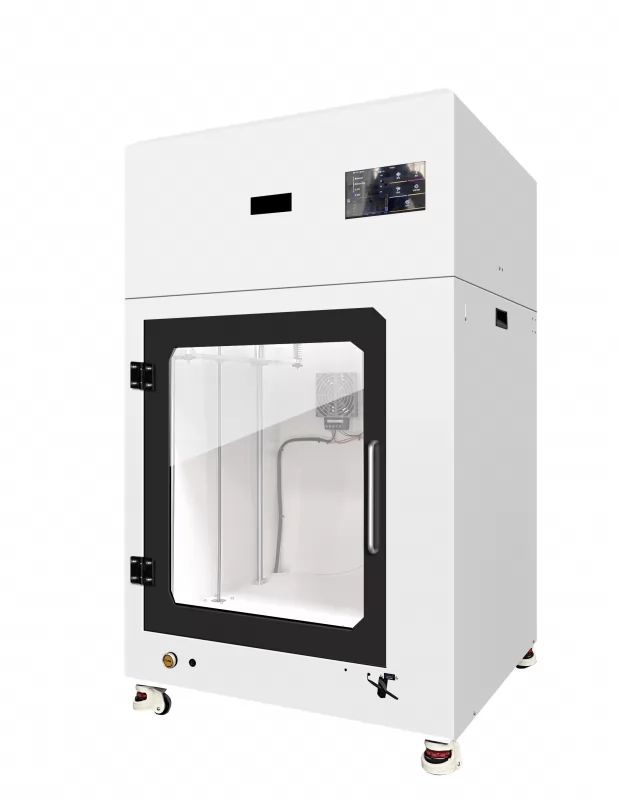

Product Description

OVERVIEW OF COLOR 3D PRINTING TECHNOLOGY: COLORJET PRINTING (CJP)

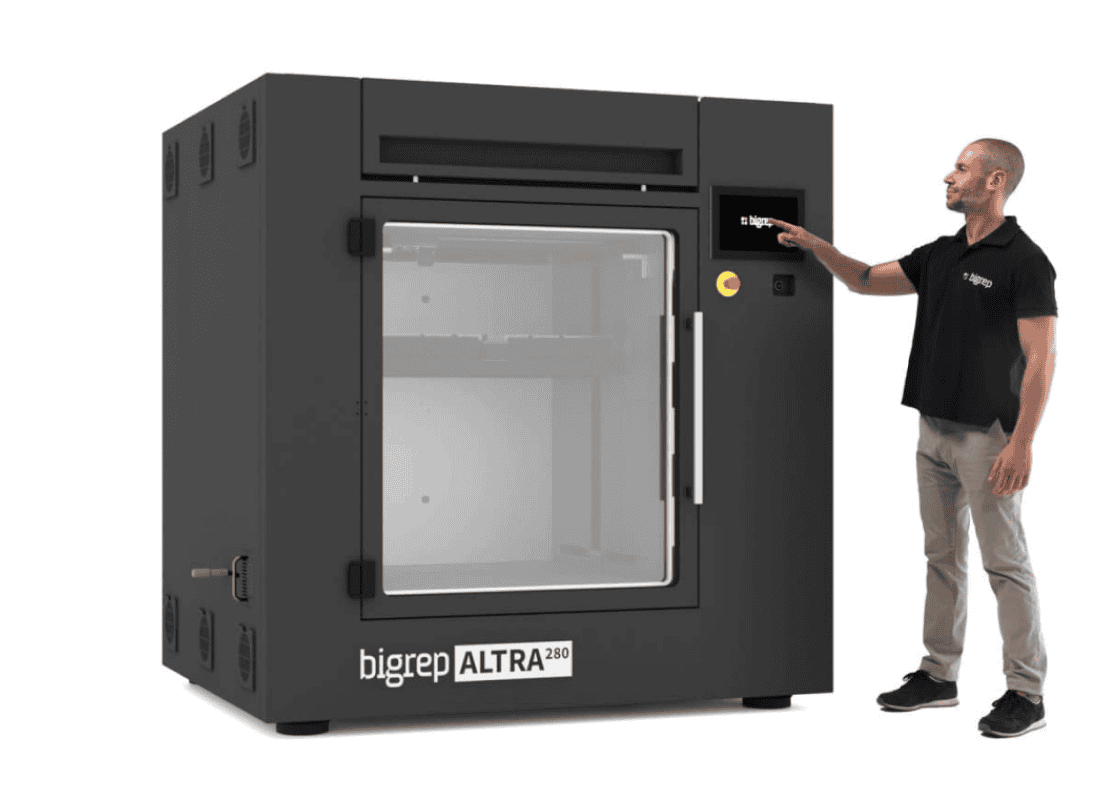

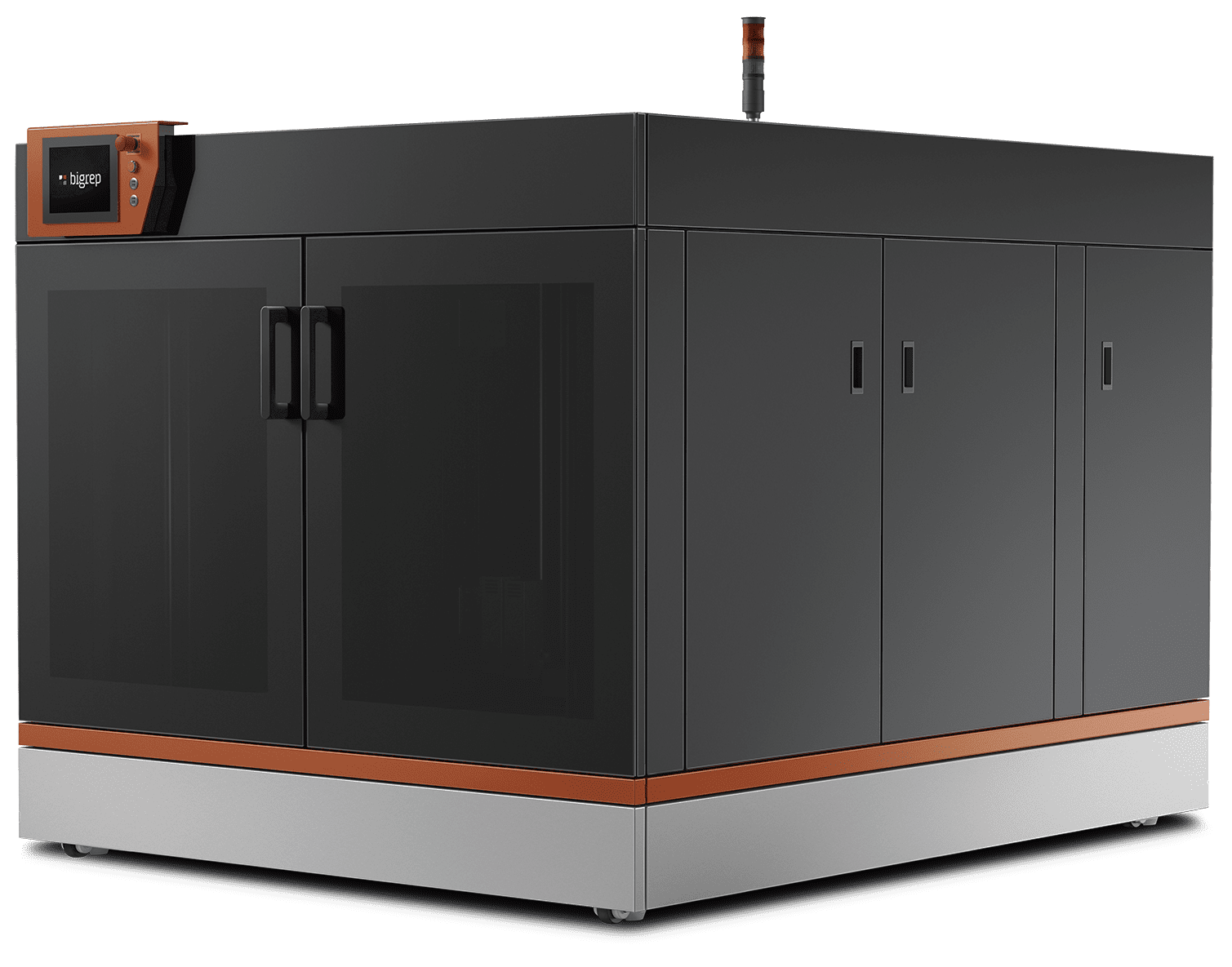

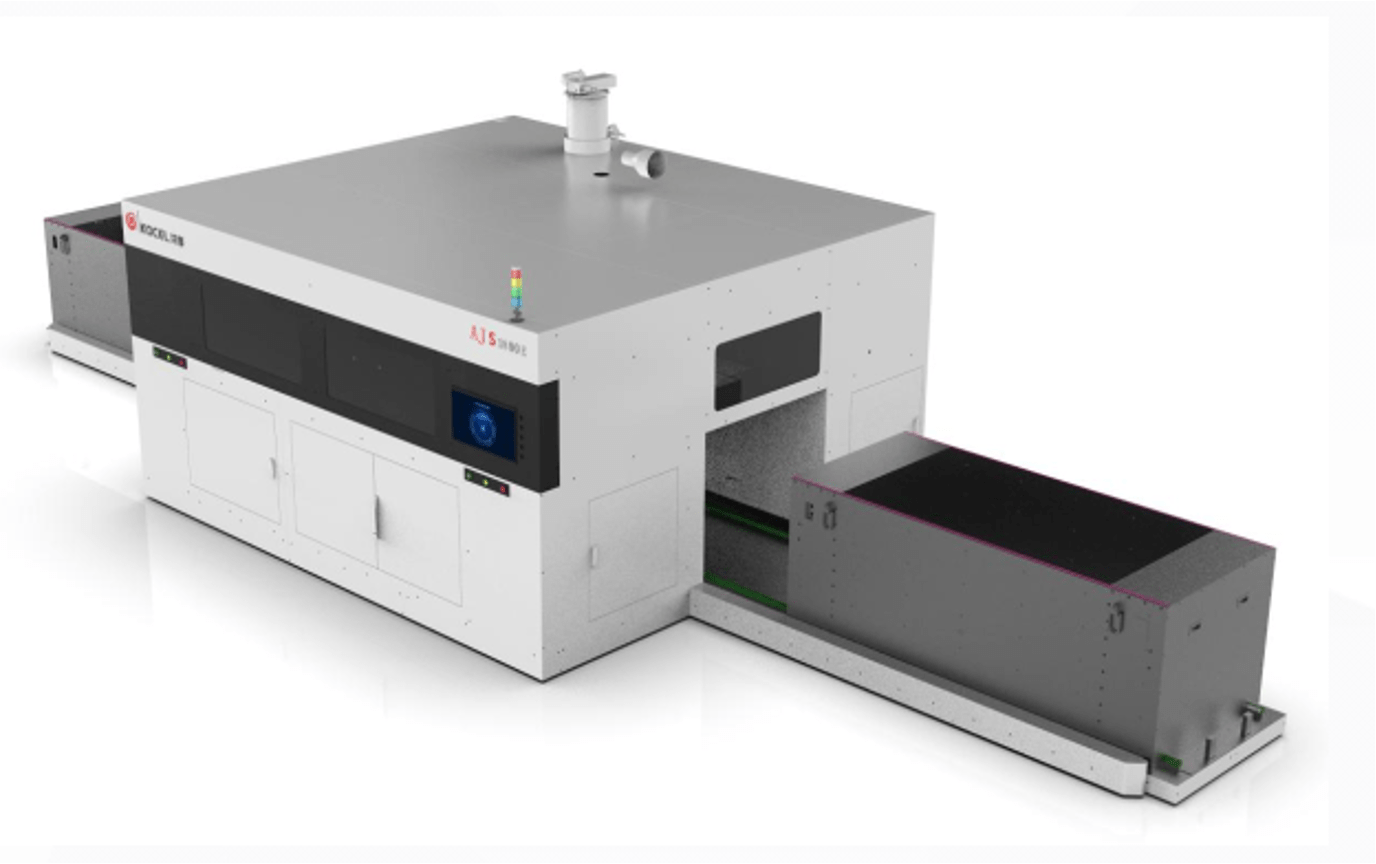

CJP technology allows the creation of millions of different colors based on the CMYK basic color system. Large print size – fast printing ability. True-to-life colors, sharp prints, flexible and easy-to-use software. Ideal for architects, consumer product design and development, education, medical models, industrial models, fine art production and more. Color 3d printers are designed for maximum performance and can be easily placed in factories or offices.

The ProJet CJP color 3d printer line is researched and developed by 3D Systems (USA).

Officially imported and distributed in the Vietnamese market by Scantech Vietnam Joint Stock Company since 2008. Up to now, color 3D printing technology has made great progress and is widely applied in all devices. Next, color simulation is needed.

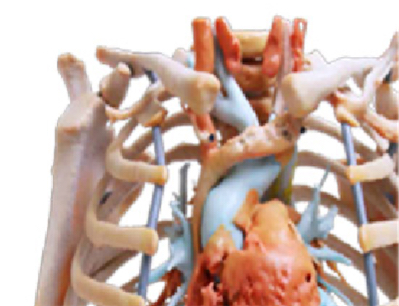

LEADING COLOR 3D PRINTING TECHNOLOGY WITH THE MOST REALISTIC FULL COLORS

Colorjet Printing is the only color 3D printing technology with no limits on color mixing ranges that creates 100% realistic products to better evaluate design ideas with accurate and consistent color specification, including Includes gradient and spectral color resolution. Products with realistically printed colors with high resolution will help customers easily see and feel their designs accurately without the need for coating. With CJP color 3d printing technology will help customers The company has the advantage to win over competitors when realizing designs in a speedy way. Quickly define, adjust and change designs in just a few hours.

LARGE PRINTING TABLE – HIGH RESOLUTION – FAST PRINTING SPEED

Designs are printed using CJP color 3D printing technology with printing speed 5-10 times faster. Printing costs are 7 times lower than all other technologies. Print multiple products in the same print run thanks to the ability to stack along the axis. Enables draft printing in monochrome printing mode for 35% faster printing. High capacity for continuous performance and long life. There are no limitations on the geometric size or profile of the object. Post-printed details result in sharp edges and realistic colors.

LARGE PRINTING TABLE – HIGH RESOLUTION – FAST PRINTING SPEED

Printing speed is 5-10 times faster. Printing costs are 7 times lower than all other technologies. Print multiple products in the same print run thanks to the ability to stack along the axis. Enables draft printing in monochrome printing mode for 35% faster printing. High capacity for continuous performance and long life. There are no limitations on the geometric size or profile of the object. Post-printed details result in sharp edges and realistic colors.

LOW OPERATING COSTS – REUSED MATERIALS

CJP uses a special powder material (with rock-like mechanical properties) monochrome white for the core structure. The mixed color layer is sprayed on the outside. Excess material after printing is sucked back up and reused for subsequent printings. No need to print a support layer. Using this efficient material will eliminate waste and reduce finishing time as support layer support is not required. Depending on the customer’s intended use, the printed product will be combined with a number of solutions such as Colorbord, StrengthMax, Slat Water, Wax to increase adhesion, hardness, and make colors brighter.

General information

| From training to commerce. 3D Systems’ color 3d printers are always the optimal choice for concepts, designs and prototyping |

| PRINCIPLES OF OPERATION: | CJP is a CJP technology that uses main materials as powder, 3 or 4 color cartridges and adhesives. The dough will be rolled into thin layers bonded together by a binder sprayed from the nozzles. All powder materials that do not participate in the shaping process will act as support layers to help connect the gaps and shape the product. You can choose to print monochrome on the ProJet CJP 360 line or both on the remaining lines. |

| FEATURE | The only technology that can print every color spectrum. Large print bed size, high resolution. Low operating costs. Fast printing – No need to print support layers, reducing total printing time by 30%. No post-processing time after printing. The printed material has mechanical properties similar to stone powder. No deformation, no warping, no discoloration after long-term use. |

| MATERIALS | Synthetic powder has hard mechanical properties similar to stone powder. Color cartridge and adhesive. |

| APPLICATION | Concept modeling: Marketing, sales and marketing models Iterate design quickly Display/art model Simulation model Practice surgery FEA analysis Multiple choice Confirm color and texture |

RELATED PRODUCTS

CONTACT

- Login /

- Register