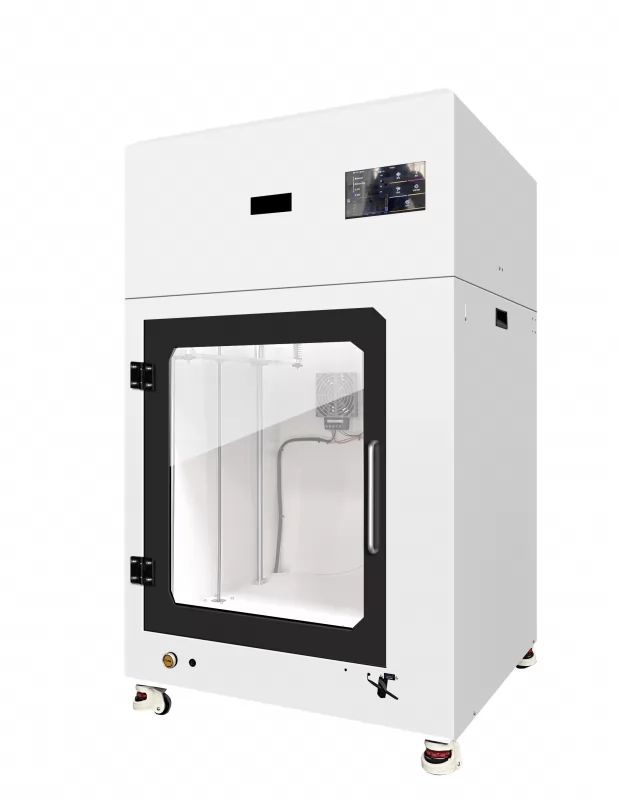

EXT 1070

Specifications

1070mm X x 1070mm Y x 1118mm Z (42”x42”x44”)

Cut

1041mm X x 990mm Y x 990mm Z (41" x 39" x 39")

Pellet nozzle diameter

0,6 mm - 9,0 mm

Pellet layer height

0,4 mm - 6,0 mm

Pellet extruder throughput

0,45kg - 13,6kg* (1lb - 30lbs*)/h

Speed

18.000 round/minute (1,5)

Product Description

LARGE FORMAT, HIGH SPEED INDUSTRIAL 3D PRINTER WITH CNC MILLING OPTION

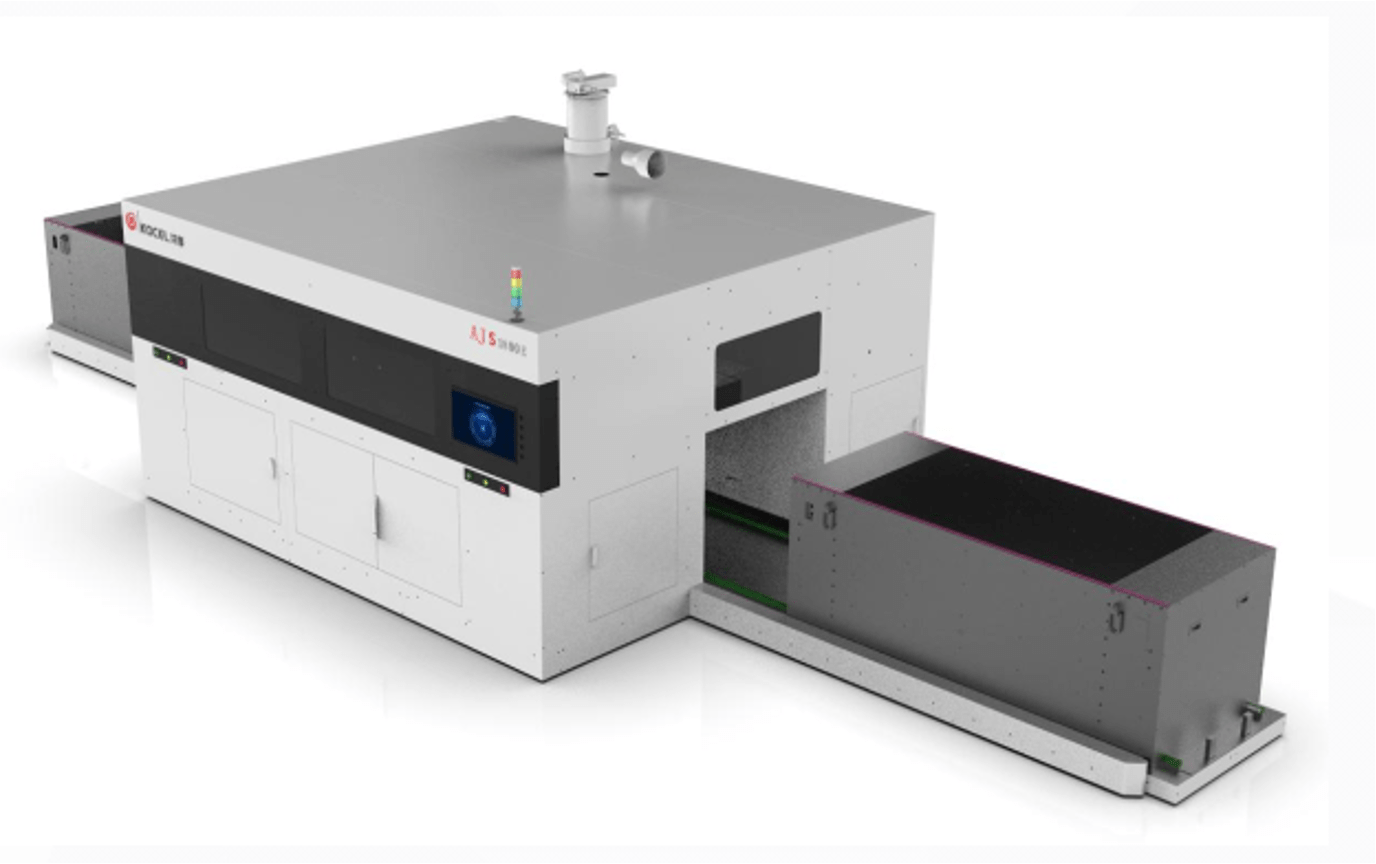

EXT 1070 Titan Pellet industrial 3D printer

High-speed, large-format industrial 3D printer with CNC milling option

The EXT 1070 Titan Pellet (formerly known as the Titan Atlas 2.5) is a high-speed, large-format industrial production 3D printing system that uses low-cost thermoplastic pellet materials.

Shorten waiting time

Print quickly with bead extrusion technology on the EXT 1070, up to 10 times faster than traditional filament extrusion 3D printing.

Reduce costs

Save costs with extrusion 3D printing using affordable thermoplastic resins, which cost up to 10 times less than traditional extrusion 3D printing materials.

3D print large sizes at the correct scale

The EXT 1070’s 3D printing space is up to 1070mm x 1070mm x 1118mm (42”x42”x44”) allowing the production of complete medium to large size parts without having to assemble pieces together.

The standard EXT 1070 3D printer is only supplied with one resin extruder, however it has the option to upgrade up to three different types of print heads, including a second bead extruder, a plastic filament and a 3-axis CNC spindle.

This makes the EXT 1070 versatile and suitable for the production of medium to large parts, with applications ranging from mold making, precision prototyping to the production of end-use parts. .

Specialized design, Ready for production

The EXT 1070 Titan Pellet is a proven production 3D printing system, dedicated to production applications such as: samples, molds, tooling, clamps, joints, end-use parts and prototypes full size. Industries that are taking advantage of Titan technology include: foundry, automotive, aerospace and defense, consumer goods, and more.

Built with a welded steel frame and industrial-grade heated housing, the EXT 1070 is ready to produce functional, high-performance parts right at the factory. The modular print head system allows customers to add a second bead extrusion head, filament printing capabilities and/or CNC milling functionality at the time of machine purchase or later.

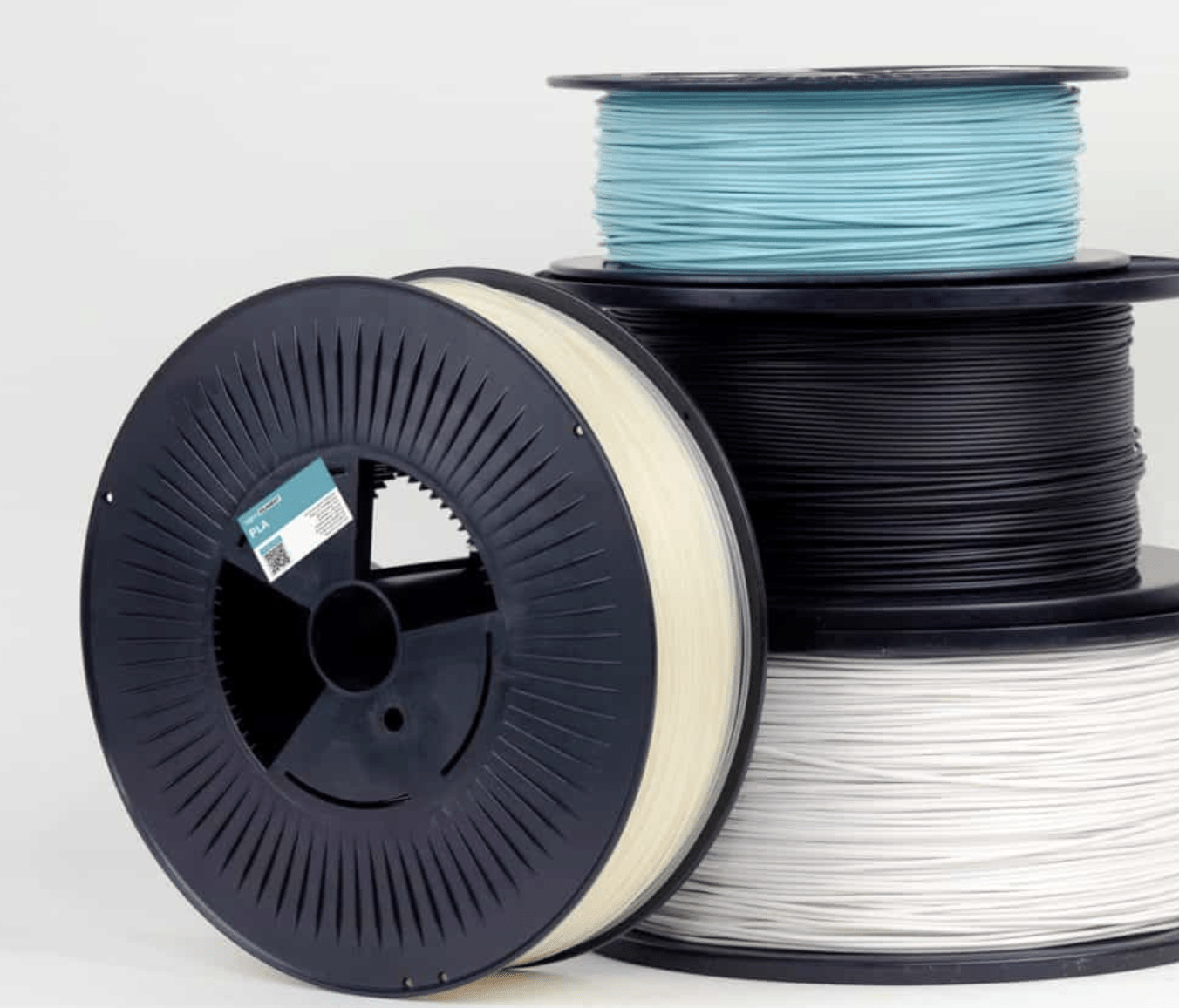

Extrusion of plastic pellets on EXT 1070

3D print with a variety of granular plastic materials, from affordable raw materials to high-temperature, high-performance materials including CF-PEI (heat-resistant plastic), GF-PEKK (excellent heat resistance) , chemical corrosion resistance, radiation resistance, electrical properties, fire resistance…) and GF-PC (glass fiber plastic).

Direct 3D printing from beads on the EXT 1070 also allows the use of highly elastic elastomers and materials containing high percentages of fiberglass and carbon.

Granular 3D printing reduces material costs by up to 10 times and material extrusion speeds are up to 10 times higher than filament 3D printing.

Integrated machining on EXT 1070

The EXT 1070 Titan Pellet can be equipped with additional print heads or other machining on the same moving gantry. Adding a second filament or particle extruder enables high-speed multi-material printing. The CNC spindle integrated head allows for production and machining of 3D printed parts both during and after the printing process. Taking 3D printing production to the next level, the EXT 1070 shortens cycle times and produces smooth, precise end-use 3D printed parts.

Industrial 3D printing production with EXT 1070

Reliable 3D printing production system:

The EXT 1070 Titan Pellet’s industrial motion control system increases uptime and reliability with CNC controls, a closed-loop system with servos on all axes, and remote monitoring capabilities.

Designed for factory:

With its precision machined welded steel frame, the EXT 1070 is a proven 3D printing production system. The machine’s enclosure is actively heated and insulated with a secure latch door, ready to operate in any production environment.

Open structure for more options:

Manufacturers can choose the right material for their application, with hundreds of granular materials available on the market for use on the EXT 1070. Printing and machining parameters can be adjusted tuned to optimize mass production applications.

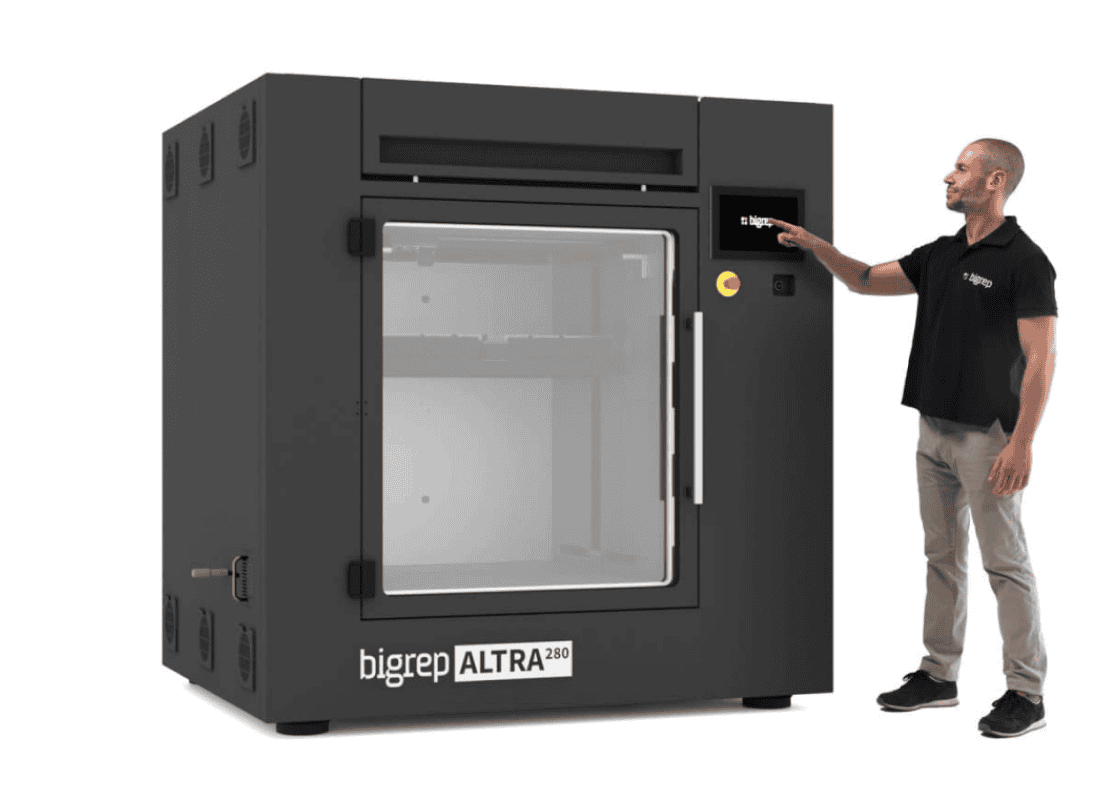

RELATED PRODUCTS

CONTACT

- Login /

- Register