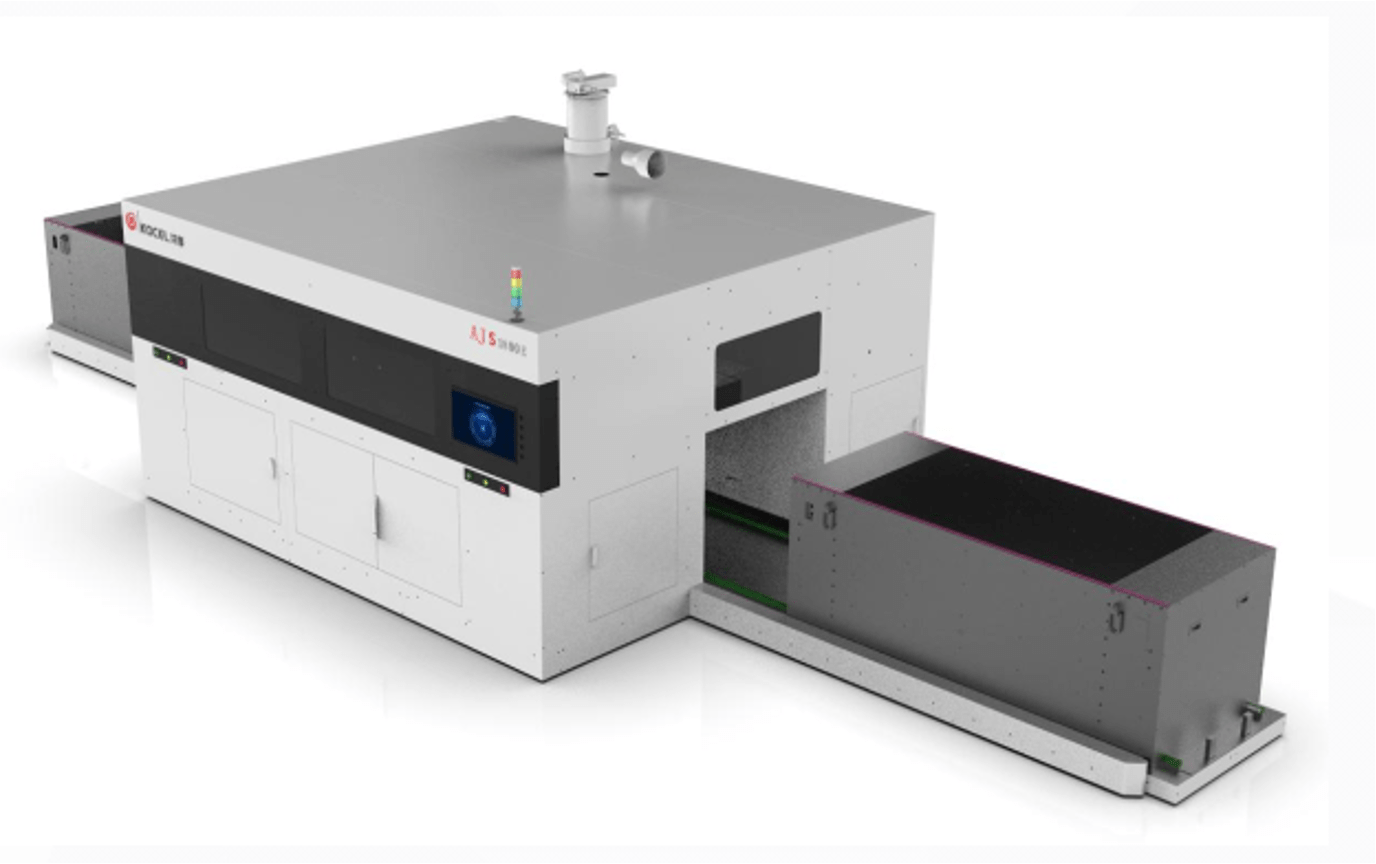

Figure 4 Production

Specifications

Max build envelope capacity ( X x Y x Z )

124.8 x 70.2 x 346 mm (4.9 x 2.8 x 13.6 in)

Software

Industry-leading 3D Sprint software for file preparation and production

Connect

Cloud connectivity for predictive and prompt service with 3D Connect

Product Description

INDUSTRY’S FIRST FULLY INTEGRATED, CUSTOMIZED FACTORY SOLUTION FOR LIVE DIGITAL PRODUCTION. IT’S Figure 4® Production.

Automation

Figure 4® Production is a custom, integrated digital manufacturing solution with a workflow powered by 3D system software. Figure 4® Production prints up to 15 times faster than other 3D printing technologies* to support automation for high-volume production.

Leading throughput

The combination of speed and precision is complemented by a light-based UV curing process, which takes minutes compared to hours with heat curing, delivering increased productivity and production times fastest additive in the world. Recent Data Highlights Figure 4® Production Production part print speeds up to 65 mm/hr and prototyping speeds up to 100 mm/hr, part accuracy and Six Sigma repeatability (Cpk > 2) on all materials.

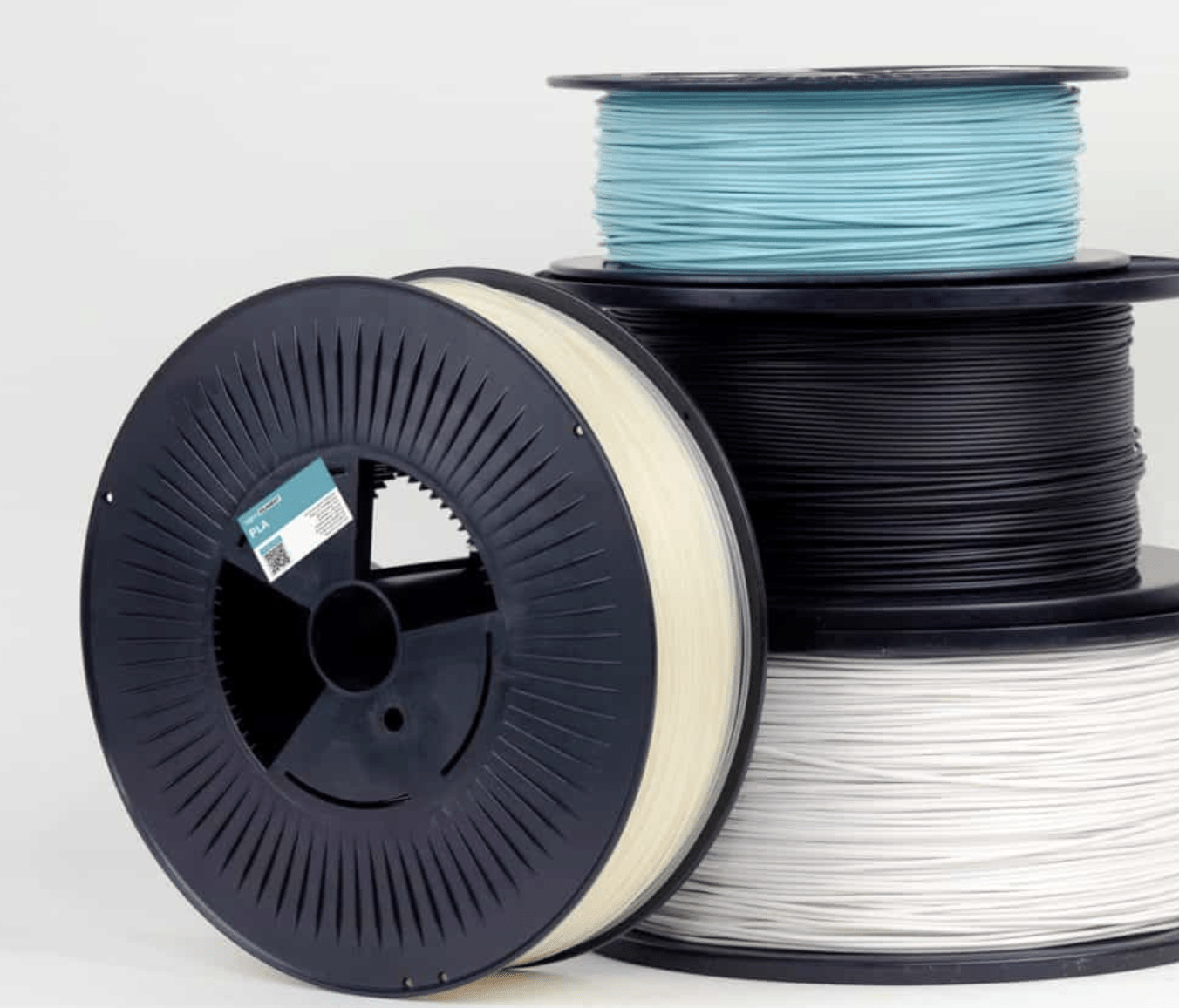

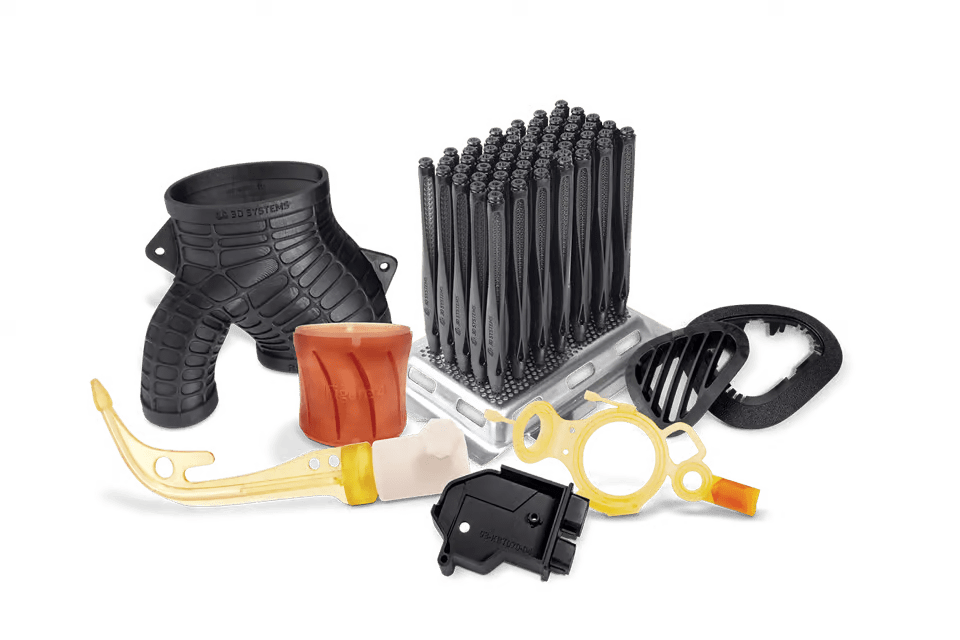

Many types of materials

The broad and ever-expanding range of Figure 4® Production materials meets a wide variety of application needs, for functional prototyping, direct production of end-use parts, molding and casting. Figure 4® Production Customers also have the option to collaborate with 3D Systems engineers to create unique materials designed specifically for their application.

Production at scale

Manufactures more than 1 million parts per year in a variety of industrial, dental and custom materials.

Flexible to fit your needs

Combines the design flexibility of additive manufacturing in configurable, inline manufacturing cells to deliver automated and customizable direct 3D manufacturing solutions.

About this printer

Direct digital production

High quality parts with good construction

Replaces traditional urethane molding and molding processes

Mass customization production

Production of dental applications

Eggshell casting application

THANK YOU TO OUR CUSTOMERS AND PARTNERS FOR ALWAYS TRUSTING AND ACCOMPANYING US.

Địa chỉ: BT6-30 Ngoại giao đoàn, phường Xuân Tảo, quận Bắc Từ Liêm, Hà Nội

Hot.line: 0862170366

Email: contact@scantechvn.com / kdscantech@gmail.com

Web: scantechvn.com

Facebook: https://www.facebook.com/scantechvn

RELATED PRODUCTS

CONTACT

- Login /

- Register