Figure 4 Modular

Specifications

Printable build volume (W x D x H): 124.8 x 70.2 x 346 mm (4.9 x 2.8 x 13.6 in)

124.8 x 70.2 x 346 mm (4.9 x 2.8 x 13.6 in)

Software

Industry-leading 3D Sprint software for file preparation and production

Connect

Cloud connectivity for predictive and prompt service with 3D Connect

Product Description

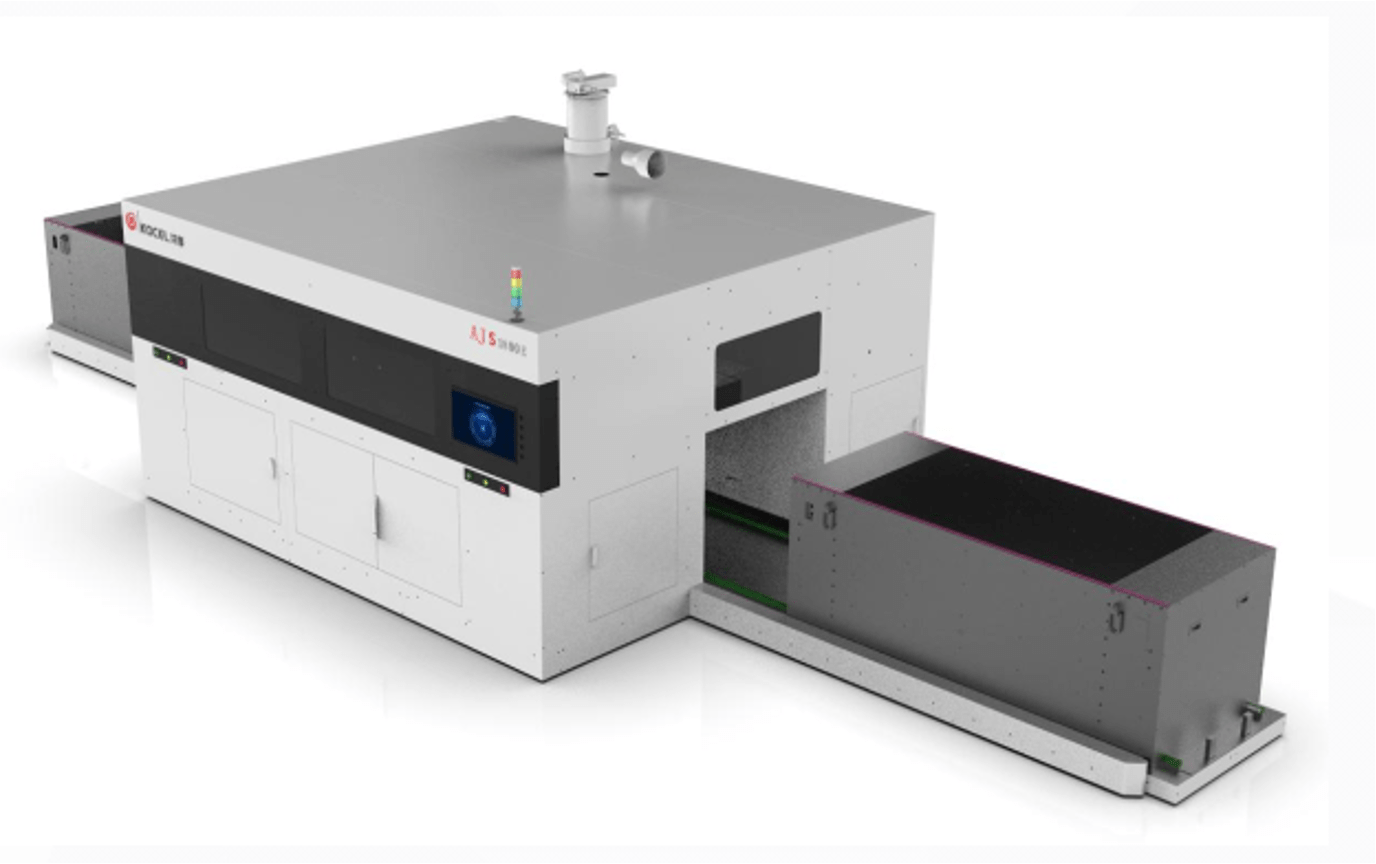

SPECIALIZED, SEMI-AUTOMATIC 3D PRODUCTION SOLUTION DESIGNED TO SCALE WITH GROWTH

Figure 4® Modular is a scalable, semi-automated 3D manufacturing solution that grows with your business, enabling capacity to meet your current and future needs, up to 10,000 parts per months, providing unprecedented production flexibility. With scalable capacity of up to 24 print engines, automated job and queuing management, automated material dispensing, and centralized post-processing, your end-to-end digital manufacturing workflow The Figure 4® Modular is ideal for low to medium volume production and bridge production. Additionally, each printer can run different materials and different jobs as part of a single high-throughput line serving the multitude of parts produced.

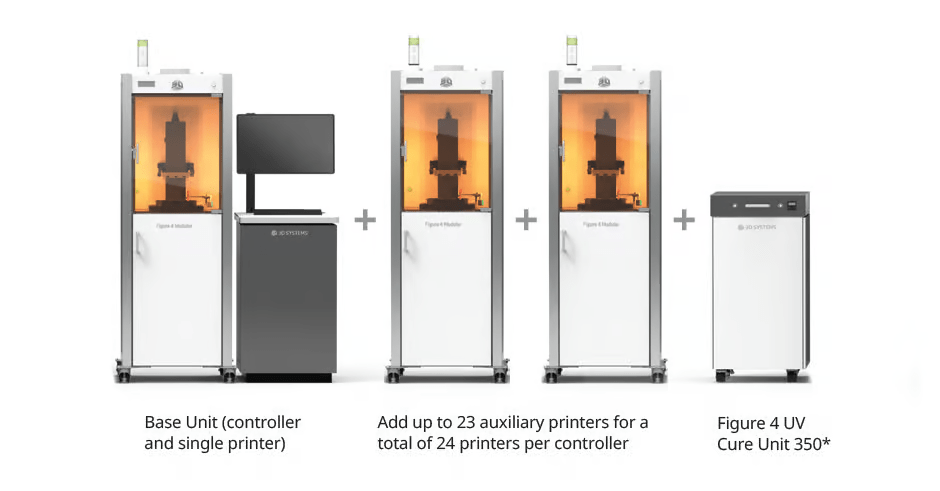

Modular extensibility

The basic configuration of the Figure 4® Modular includes a printer and central controller. This can be easily expanded to up to 24 printer modules on a single controller, with flexibility in layout configuration, allowing production to multiply rapidly without disrupting the production floor. .

Low total operating costs

Figure 4® Modular allows companies to move directly to manufacturing from digital CAD files, bypassing machining costs and delays to begin delivering final parts immediately. This semi-automated solution reduces labor through automated job and queuing management as well as an automated material feeding system.

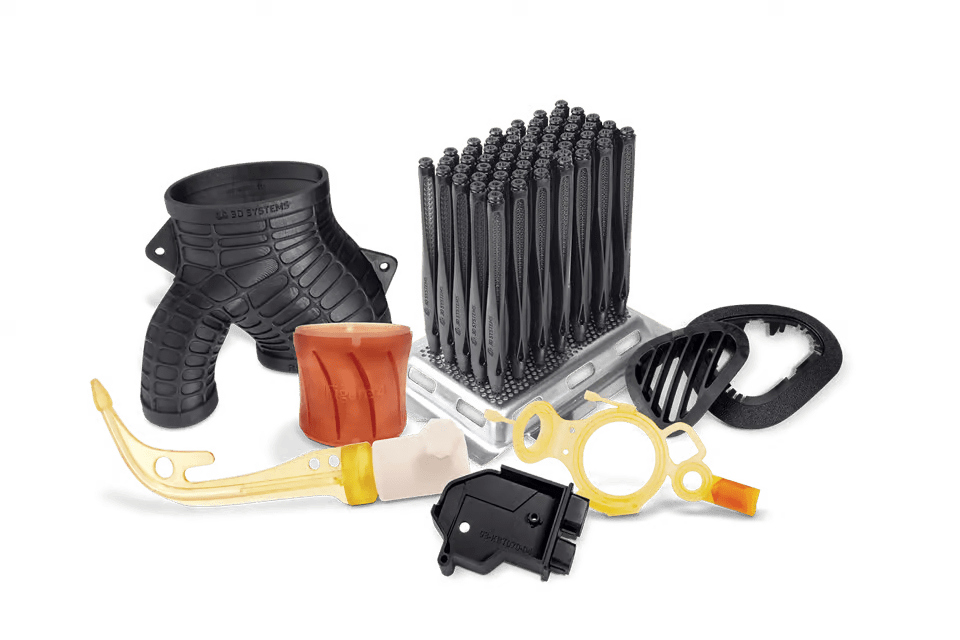

Unparalleled versatility

The Figure 4® Modular’s individual printers enable the simultaneous production of a variety of part sizes and shapes, in a variety of materials, for a variety of part types for production and prototyping.

Productivity from start to finish

Quick and easy print job preparation, ultra-fast print speeds, processing in minutes instead of hours, and production management ensure high part productivity with high accuracy and repeatability.

Many types of materials

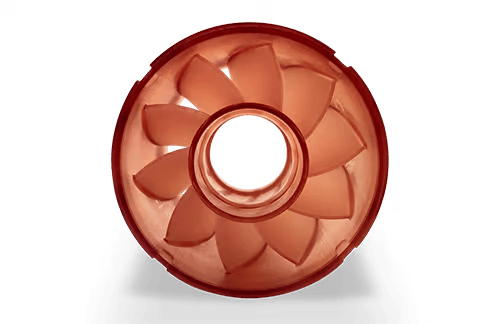

3D Systems’ Materials Design Center has more than 30 years of R&D experience and proven process development expertise. The wide and ever-expanding material range available for Figure 4 Modules meets a wide variety of application needs, for functional prototyping, direct production of end-use parts, molding and casting, and composed of thermoplastic, rubber-like thermoplastic, hard and durable. The material is resistant and biocompatible.

*Note: Not all materials are available in all countries – please consult your local sales representative for availability.

Revolutionize production

Scalable, semi-automated 3D manufacturing solution designed to grow with your prototyping and production needs. Enables companies to go directly to manufacturing from digital CAD files to immediate delivery of final parts.

Speed and flexibility

Same-day prototyping and live 3D manufacturing of up to 10,000 parts per month. Additionally, each printer can run different materials and different jobs as part of a single high-throughput line serving the multitude of parts produced.

Replaces traditional urethane molding and molding processes

Create rapid functional prototypes and rapid conceptual models

Durable end-use plastic parts

Low volume bridge production

Short-term production of plastic products

Quick tooling – molds and master samples

Consumer high temperature application with transparency

Elastomeric parts – prototypes of washers, washers, hoses, waterproof panels, tubes, gaskets, gaskets and other vibration damping parts

THANK YOU TO OUR CUSTOMERS AND PARTNERS FOR ALWAYS TRUSTING AND ACCOMPANYING US.

Địa chỉ: BT6-30 Ngoại giao đoàn, phường Xuân Tảo, quận Bắc Từ Liêm, Hà Nội

Hot.line: 0862170366

Email: contact@scantechvn.com / kdscantech@gmail.com

Web: scantechvn.com

Facebook: https://www.facebook.com/scantechvn

RELATED PRODUCTS

CONTACT

- Login /

- Register