METAL 3D PRINTING FACTORY DMP Factory 350 & DMP Factory 350 Dual

Specifications

Tech

Using Direct Metal Printing (DMP) technology Automatic and self-contained powder management

Construction volume (W x D x H)

275 x 275 x 420 mm

Vacuum chamber is safe

O2 environment below 25ppm Fast two-dimensional powder deposition

Specialized materials

LaserForm Ni718, LaserForm Ni615, LaserForm Ti Gr23, LaserForm Ti Gr5, La serForm Ti Gr1, LaserForm AlSi10Mg, LaserForm AlSi7Mg0.6, LaserForm CoCrF75, LaserForm 316L, LaserForm 17-4PH, Thép LaserForm, AMPO M789, Vonfram, Nhôm A6061

Laser/ Resolution

1 or 2 or 3 x 500 W lasers/Fiber Lasers ± 0.1-0.2% with a minimum of ± 100 μm

Product Description

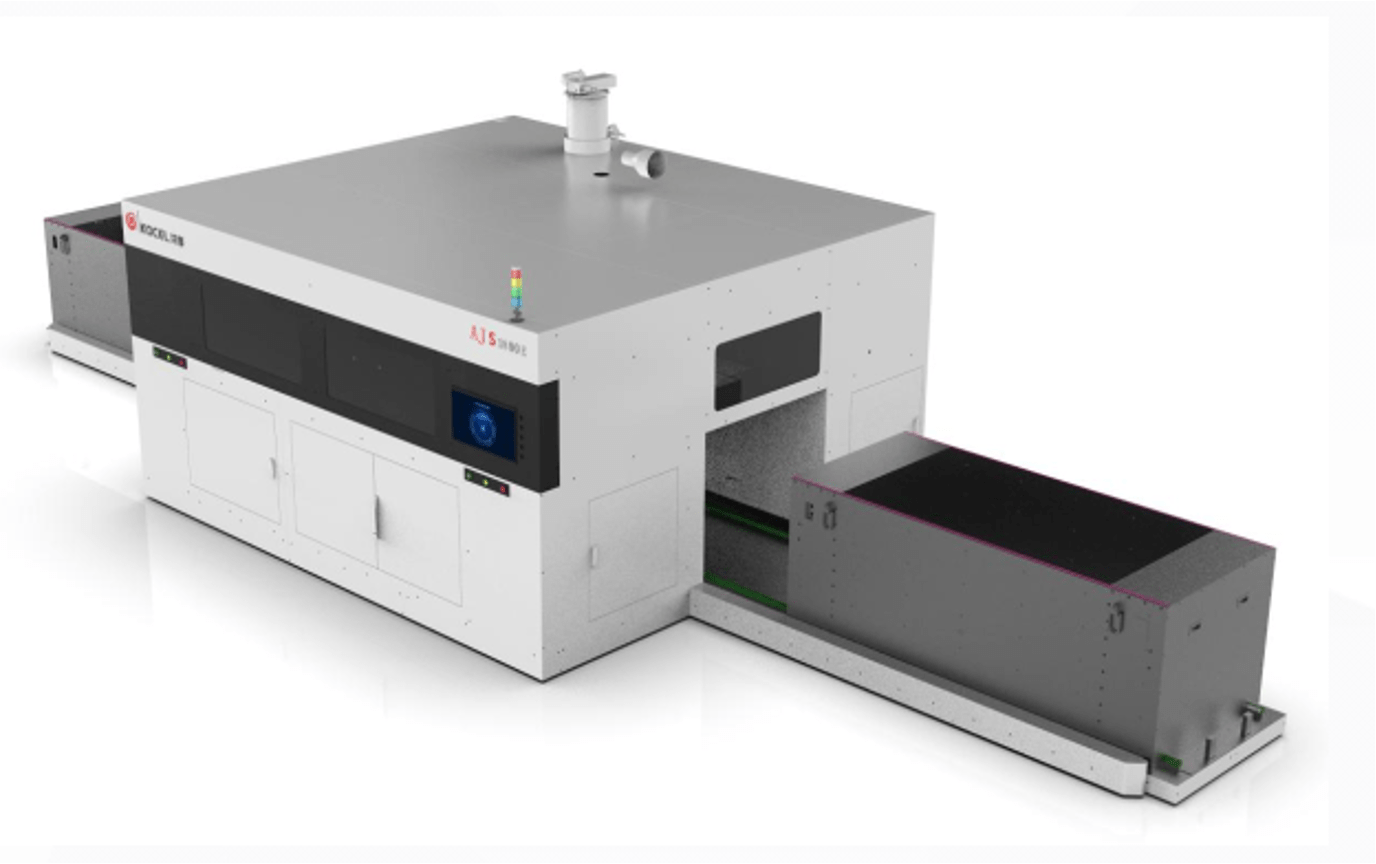

DMP Factory 350 & DMP Factory 350 Dual ARE DESIGNED TO BE SCALABLE TO A FACTORY SCALE with integrated powder management

HIGH QUALITY METAL POWDER MATERIAL MANAGEMENT PROCESS

- The DMP Factory 350 3D printer features an integrated powder material management system with a high-performance screening system. Thus significantly limiting customer contact with powdered materials.

- An O2 environment below 25ppm ensures superior print quality and optimal material usage. This results in exceptionally dense parts with excellent mechanical properties.

- Automated workflows help customers scale metal production in the most efficient way. The management system monitors the process in real time and adds intelligent traceability.

- The DMP Factory 350 has a two-laser configuration, which reduces construction time by up to 50%. The DMP Factory 350 Dual maintains the high quality and repeatability of single laser configurations while increasing productivity to reduce operating costs.

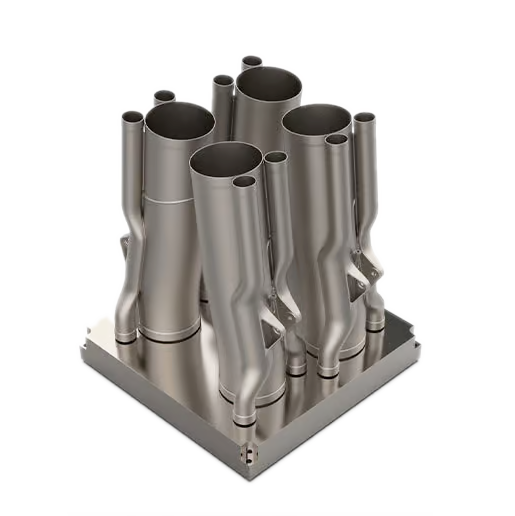

| Integrated material management High-throughput, highly repeatable metal AM systems produce precision-quality parts from a variety of alloys with high-quality material management for maximum powder utilization. For companies scaling up metal production and requiring operators to limit exposure to powders. | Bracket for mounting the geographic communication antenna reflector. Structurally optimized struts allow for weight reduction and cost savings. |

|  |

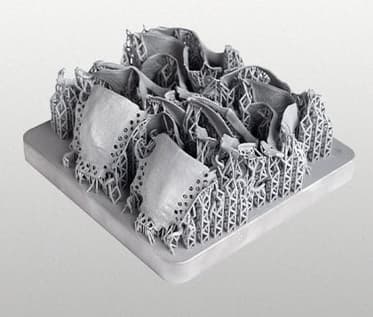

| The construction of the DMP 350 series delivers optimal printed pattern quality even for complex mesh designs and challenging alloy materials | |

| EFFICIENCY DMP 350 FLEX BRINGS | |

|

|

|

Increases stiffness to weight ratio Titanium brackets produced by DMP are 25% lighter than those produced by milling and have a better stiffness-to-weight ratio. |

Reduce implementation time Avoid long and complicated manufacturing processes by reducing assembly steps. |

|

|

|

Improved function optimization Combined with 3DXpert software, a multitude of scaffold structures are created, allowing for better osseointegration with orthopedic implants, for example. |

Increase performance and mold life Thanks to design freedom, mold performance is improved thanks to better thermal optimization during plastic injection or molding. |

Printing 500,000 challenging parts every year

The DMP Factory 350 and DMP Factory 350 Dual have been developed through a continuous feedback loop between the manufacturing teams at our advanced manufacturing and product development centers. With this technology, 3D Systems offers you an integrated solution for metal additive manufacturing. They with unique features, an extensively tested LaserForm material suite, 3DXpert metal additive manufacturing software and, ultimately, the expertise of our applications engineers helps our customers realize time, cost and functionality benefits efficiently and reliably.

THANK YOU OUR CUSTOMERS AND PARTNERS FOR ALWAYS TRUSTING AND ACCOMPANYING US

Địa chỉ: BT6-30 Ngoại giao đoàn, phường Xuân Tảo, quận Bắc Từ Liêm, Hà Nội

Hot.line: 0862170366

Email: contact@scantechvn.com / kdscantech@gmail.com

Web: scantechvn.com

Facebook: https://www.facebook.com/scantechvn

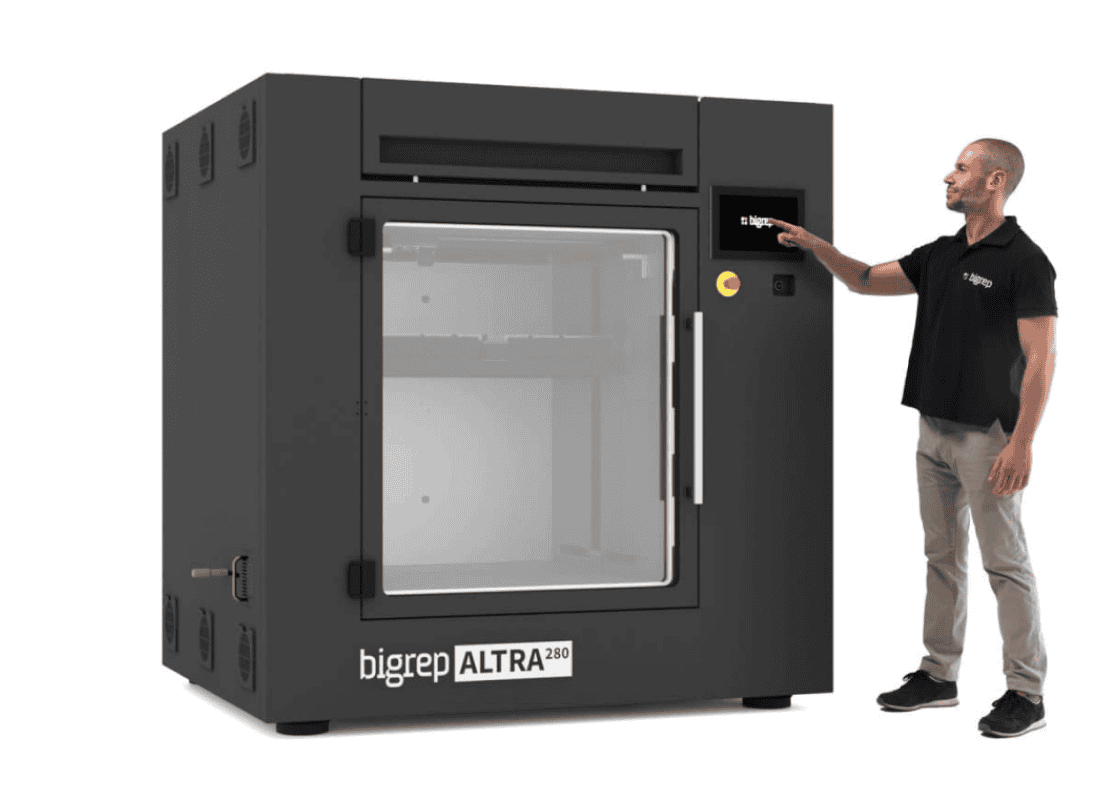

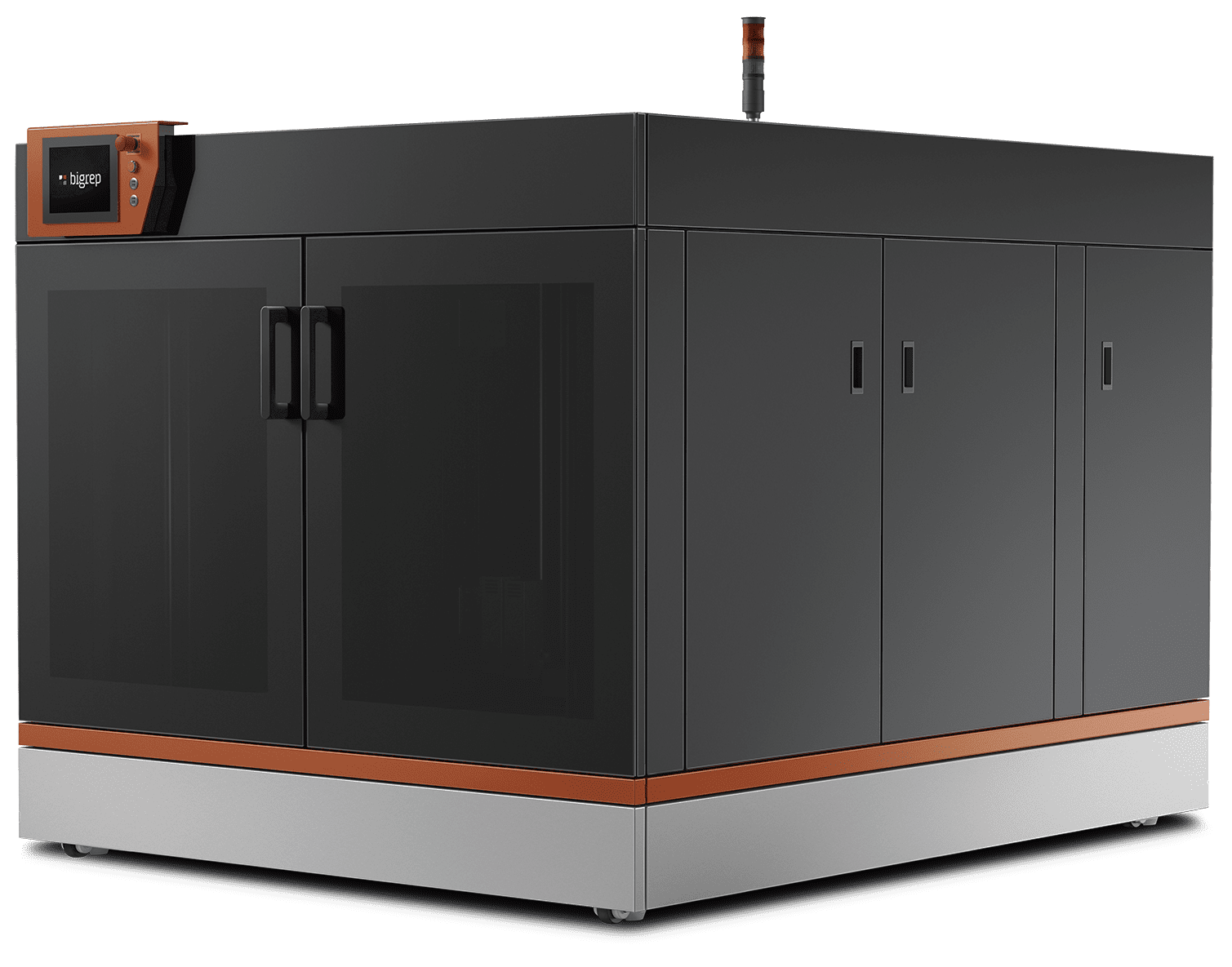

RELATED PRODUCTS

CONTACT

- Login /

- Register