SLA 3D printing makes printing giant samples simpler

Each form of 3D printing has different advantages and disadvantages, however, SLA is a 3D printing method that has many outstanding optimizations when it can mass produce large-format printed models while still meeting the requirements. Smoothness of surface and perfect details. Our radar 3D printing model has received positive feedback from customers thanks to the thoughtful product package implementation process at a preferential price.

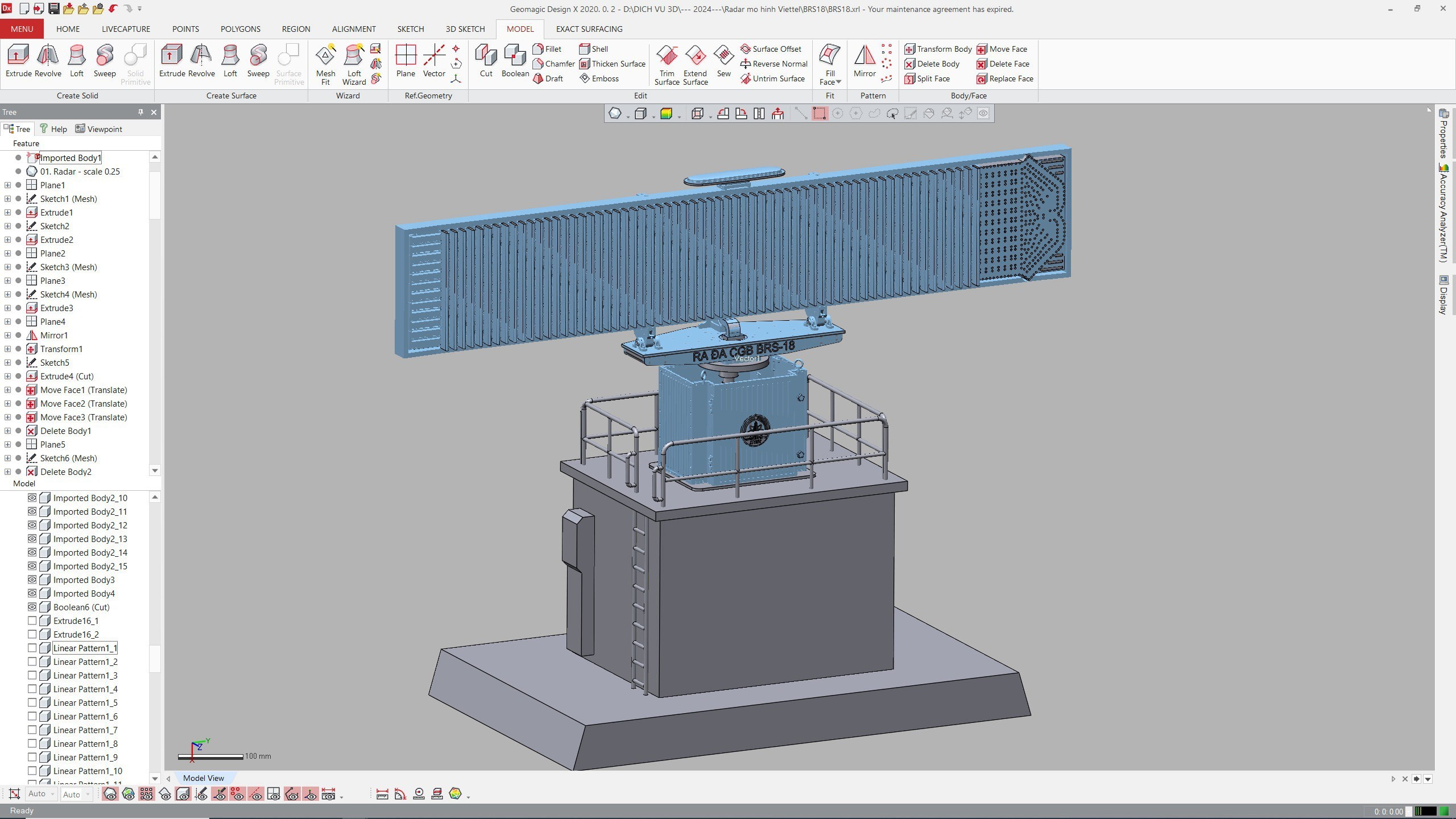

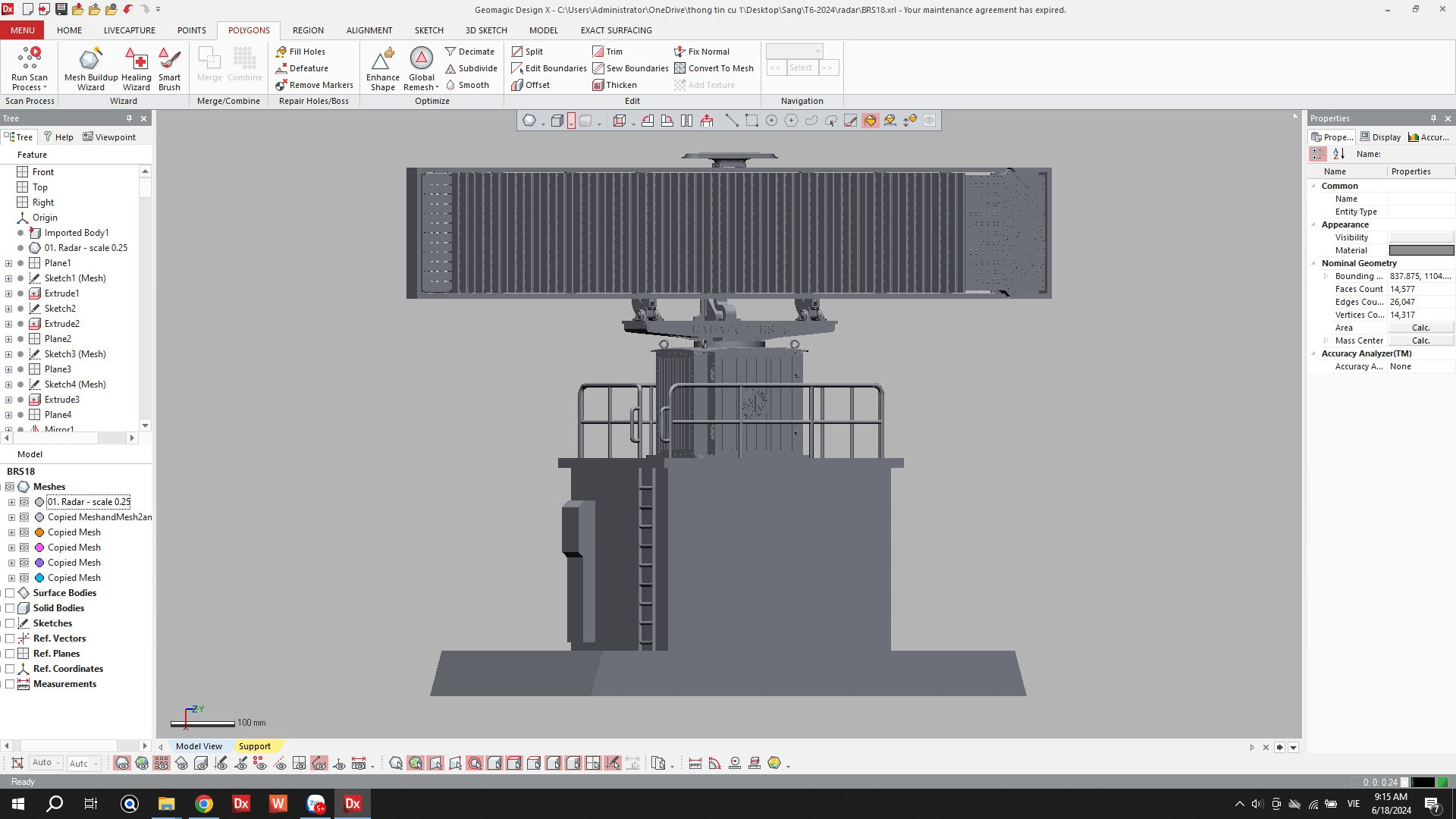

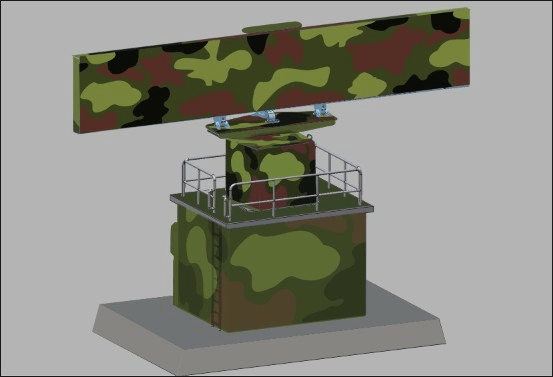

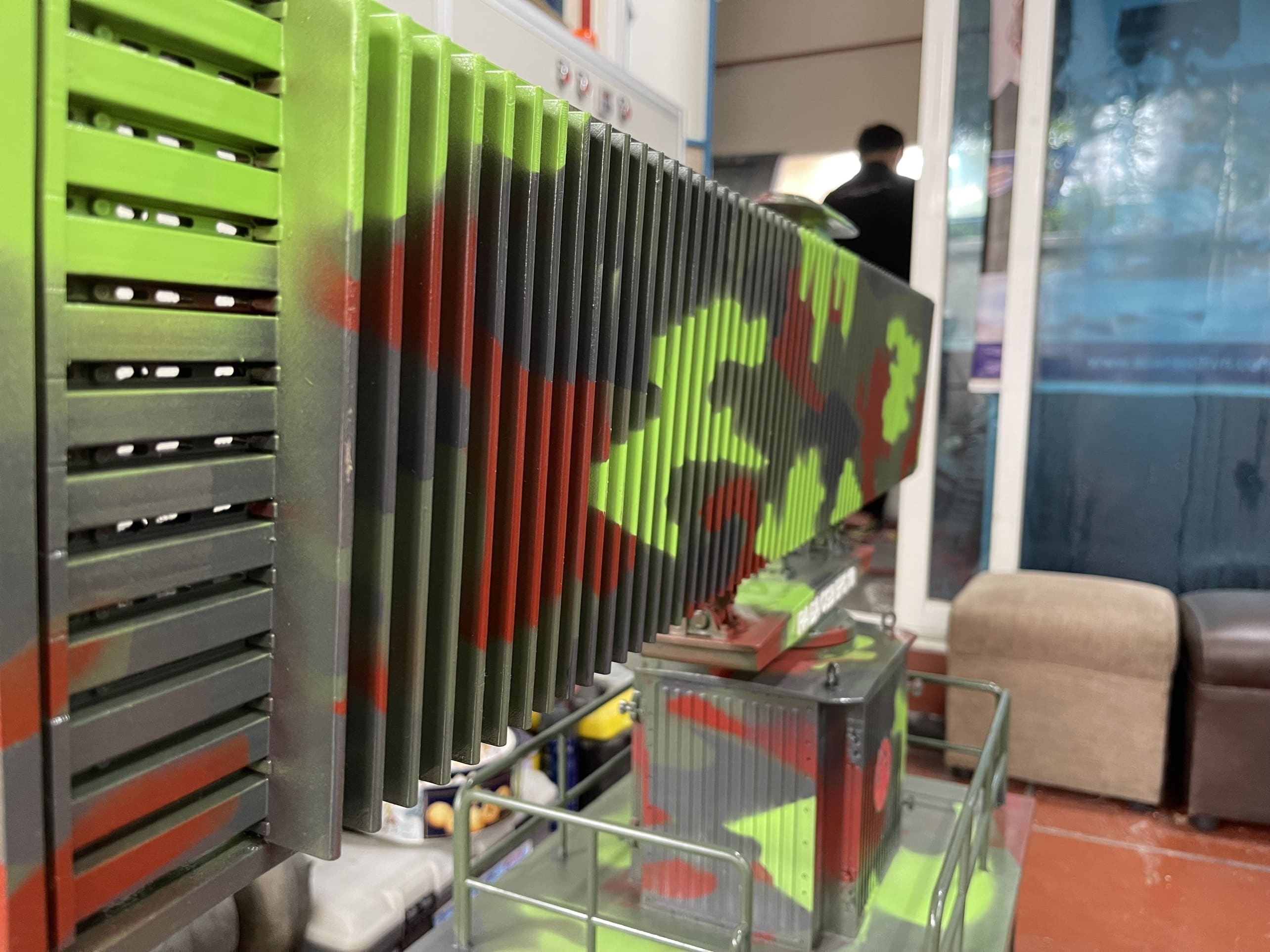

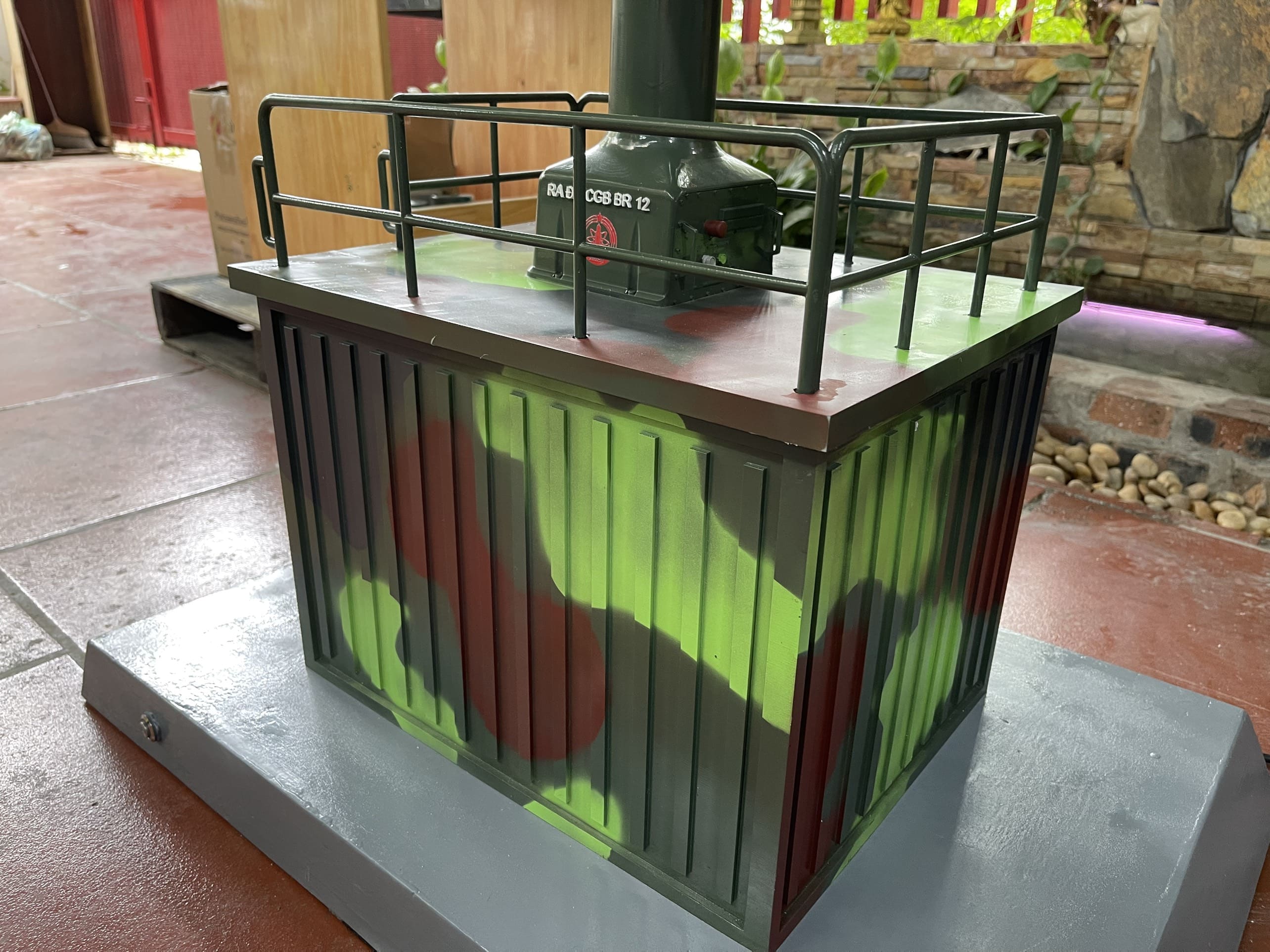

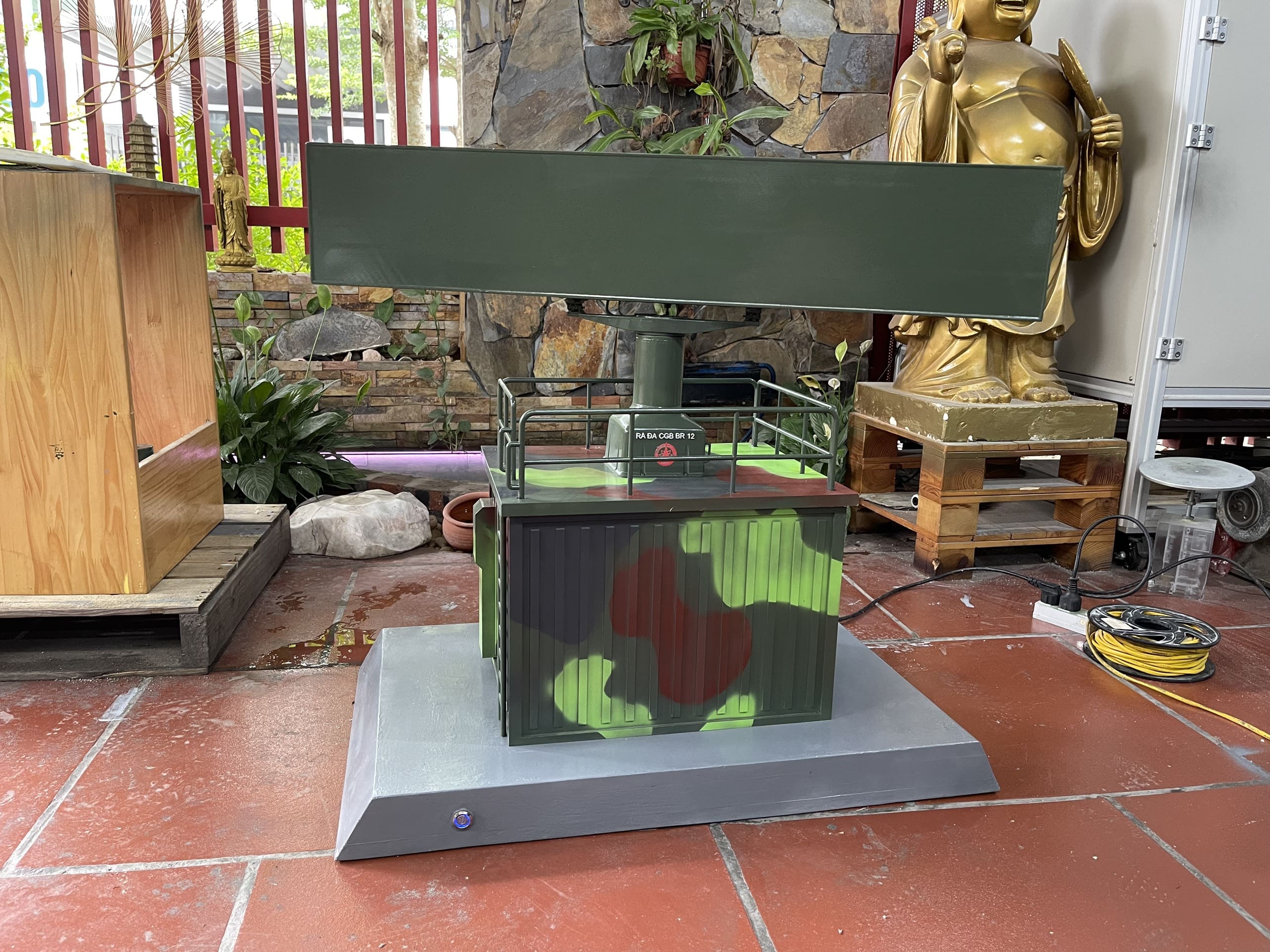

The requirements of the printed products of the Radar Model Project BRS 18 (camouflage paint) and BR12 (military color paint) this time are extremely complex and demanding.

Compared to previous products that Scantech has made, the Radar 3D printed model is somewhat more complicated due to the rotating shaft structure inside the core. This requires Scantech’s careful design and post-print assembly.

SPECIAL IMPORTANT TECHNIQUES – REQUIRING DETAIL IN EACH STAGE OF IMPLEMENTATION.

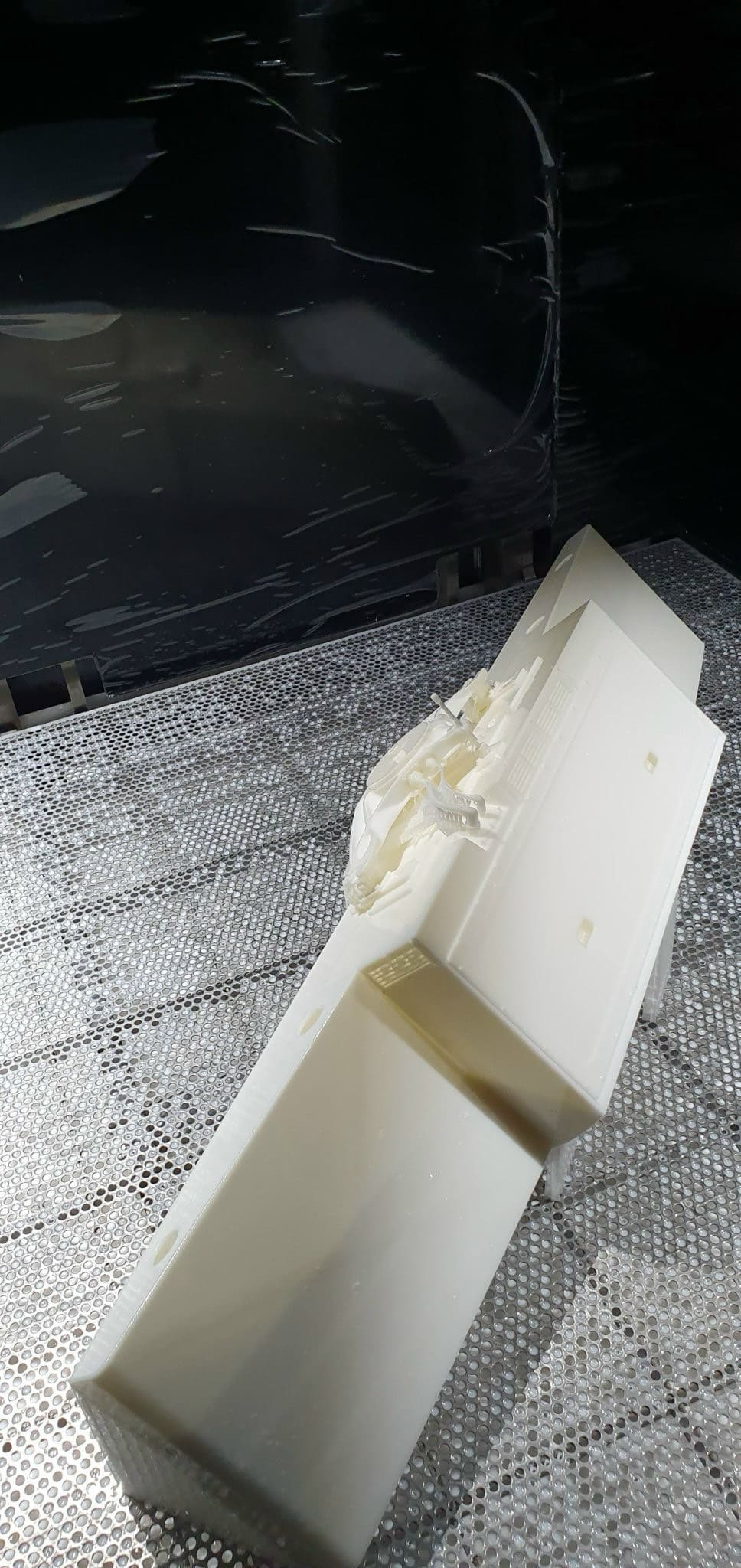

Separate the model for printing and reinforce it with a wooden frame inside.

Base: Made of wood, painted cement color.

Radar base: Hollow rectangular wooden box inside to install the rotating mechanism including motor and rotating shaft.

The outside is a 3D printed radar shell, fixed with glue to a wooden box.

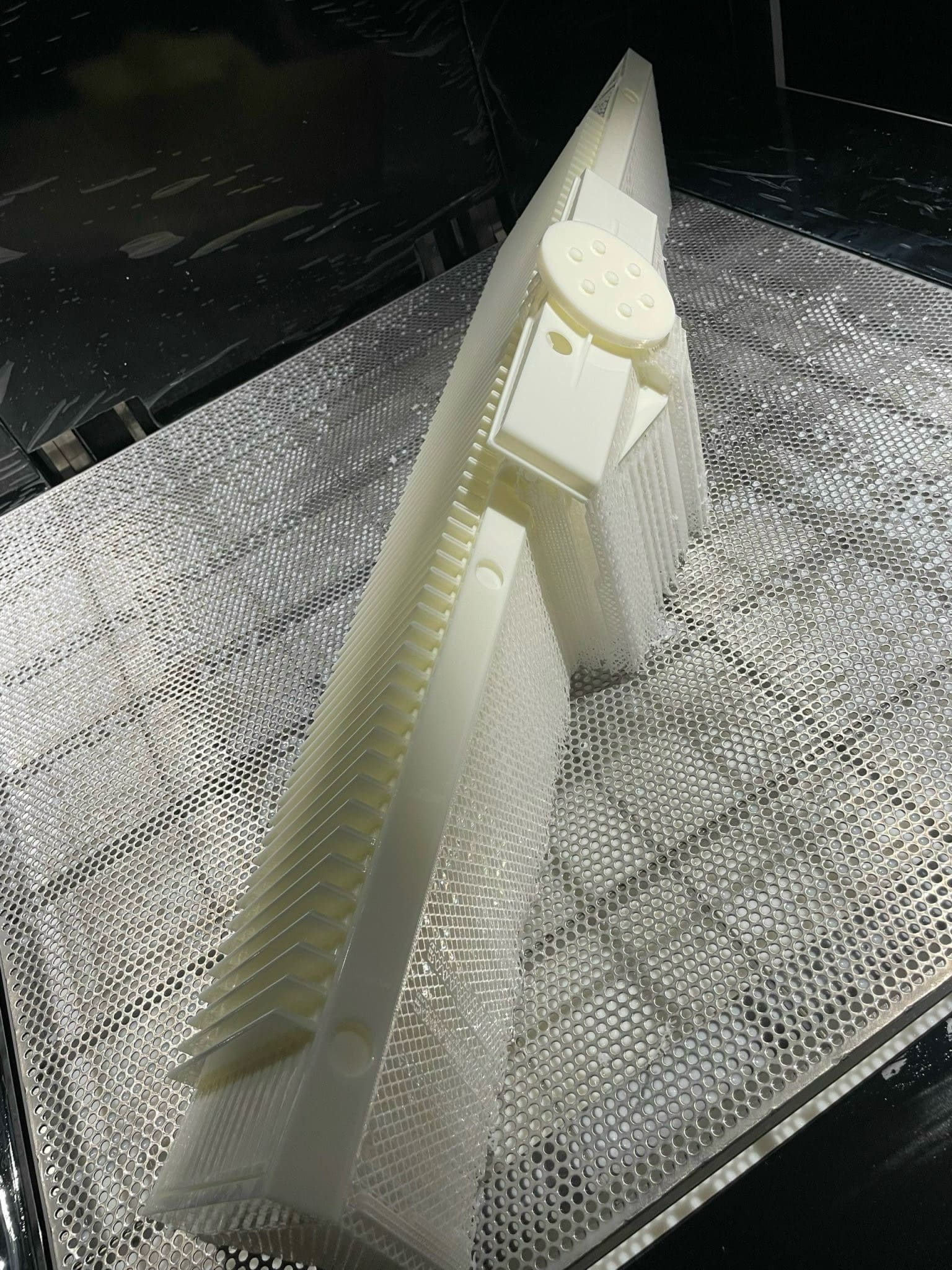

Radar support shaft: Mounted on the base and attached to the radar rotor. The plastic printed support shaft has a hole inside to attach the rotating shaft and fix the bearing system to fix the shaft.

Radar rotor: Mounted on the radar shaft, completely 3D printed with centering pin to attach to the support shaft.

Radar rotating shaft system: Made of steel designed to attach 2 bearings at the top and bottom ends.

One end is attached to the motor with a soft joint, the other end is attached to the radar rotor through a support base made of steel bolted to the shaft.

Motor: Gear reduction motor, speed 10 rpm, uses 220v voltage.

Switch: Blue LED Power Hold Push Button, 19mm diameter, 304 Stainless Steel material, 5-Pin 220V type.

Turn on the LED switch to light up the engine, press the LED off button to turn off the power.

Power cord: 220V molded wire 1.5m long.

Wood: Pine wood thickness 18mm.

Therefore, if even one small detail here is different, it will cause the product to fail.

- That requires our staff to coordinate well from designing 3D printing files to printing and assembling and painting.

- The paint color version is also pre-designed to discuss with customers about their level of satisfaction or desire for correction.

Large format radar 3D printing sample from customer

LARGE FORMAT RADAR 3D PRINTING PROCESS AT SCANTECH

STEP 1:

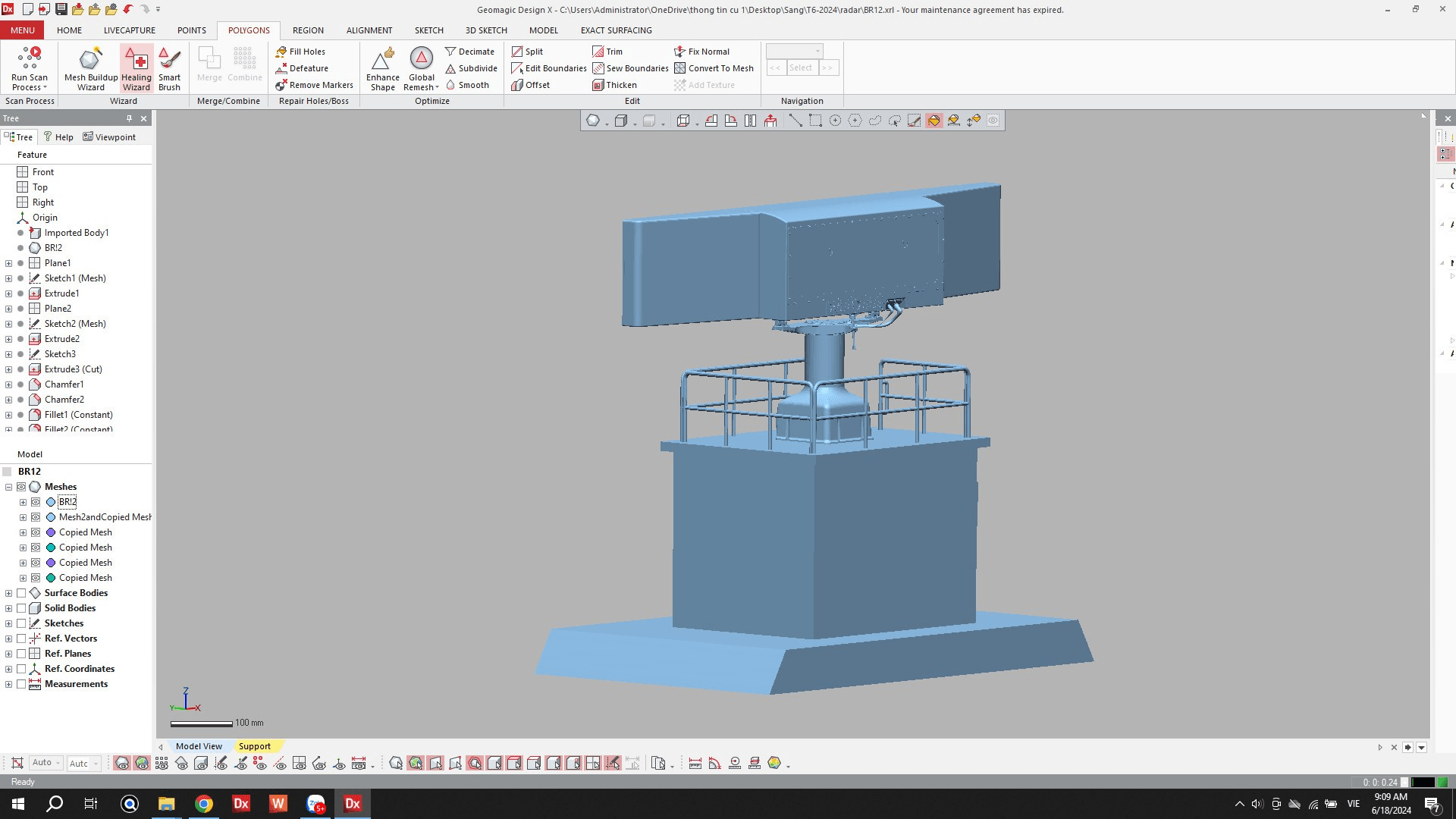

Receive the customer’s file, scale the model file to ¼ of the actual size of the model

STEP 2:

After scaling to ¼ scale, check the printed file on the software to see if the file is thick enough to print

STEP 3

Calculate and redesign both files to fit the rotating mechanisms inside

STEP 4:

Fix the file, redesign, complete the file according to customer requirements and have enough thickness for printing

STEP 5: Cut the file into parts then export and print

STEP 6: After printing, support processing and painting

STEP 7: Install the rotating mechanism and put the parts together and complete the product

Some views of the RADAR 3D printed model

FINISHED PRODUCT

VIDEO SHOWING OUR GIANT RADAR 3D PRINTED MODELS

WHY SHOULD YOU CHOOSE US FOR THE PRODUCTION OF LARGE FORMAT 3D PRINTED MODELS?

With many years of experience in the field of 3D digitization, along with being a pioneer in the field in Vietnam, Scantech is confident that it can provide the best 3D printing quality today. With a large number of domestic and foreign partners, we have established loyal customers with the quality of our products.

- Experts have more than ten years of experience directly consulting customers.

- Technician with at least 7 years of experience directly designing 3D files.

- Quickly handle problems during and after 3D printing – ensuring customers are always satisfied when entrusted.

“We build trust with customers from practical experience and product quality.”

Please refer to:

- https://scantechvn.com/du-an-so-hoa-3d-tuong-dai-to-quoc-ghi-cong-tai-bac-ninh/

- https://scantechvn.com/du-an-so-hoa-3d-dai-tuong-phat-a-di-da-tren-dinh-fansipan-sapa-lao-cai/

Large 3D printing workshop promises to meet both quantity and quality.

3D scanning is no longer a distant expectation in Vietnam.

OTHER NEWS