INDUSTRIAL 3D PRINTER & 3D PRINTING FACTORY LINE

Product portfolio

5 "INCREDIBLE" EFFECTS FROM 7 3D PRINTING TECHNOLOGIES:

- Create perfectly functional 3D Printed models, meeting all the most stringent international standards on: Material mechanical properties, accuracy level, printed layer smoothness and durability. difficulty of printing model.

- Shorten Design time, speed up innovation and New Product Development.

- Completely eliminate all costs for traditional mold prototyping.

- Save time, labor costs, risk costs.

- Huge competitive opportunity for businesses to prove their production capacity, improve quality and reduce product costs.

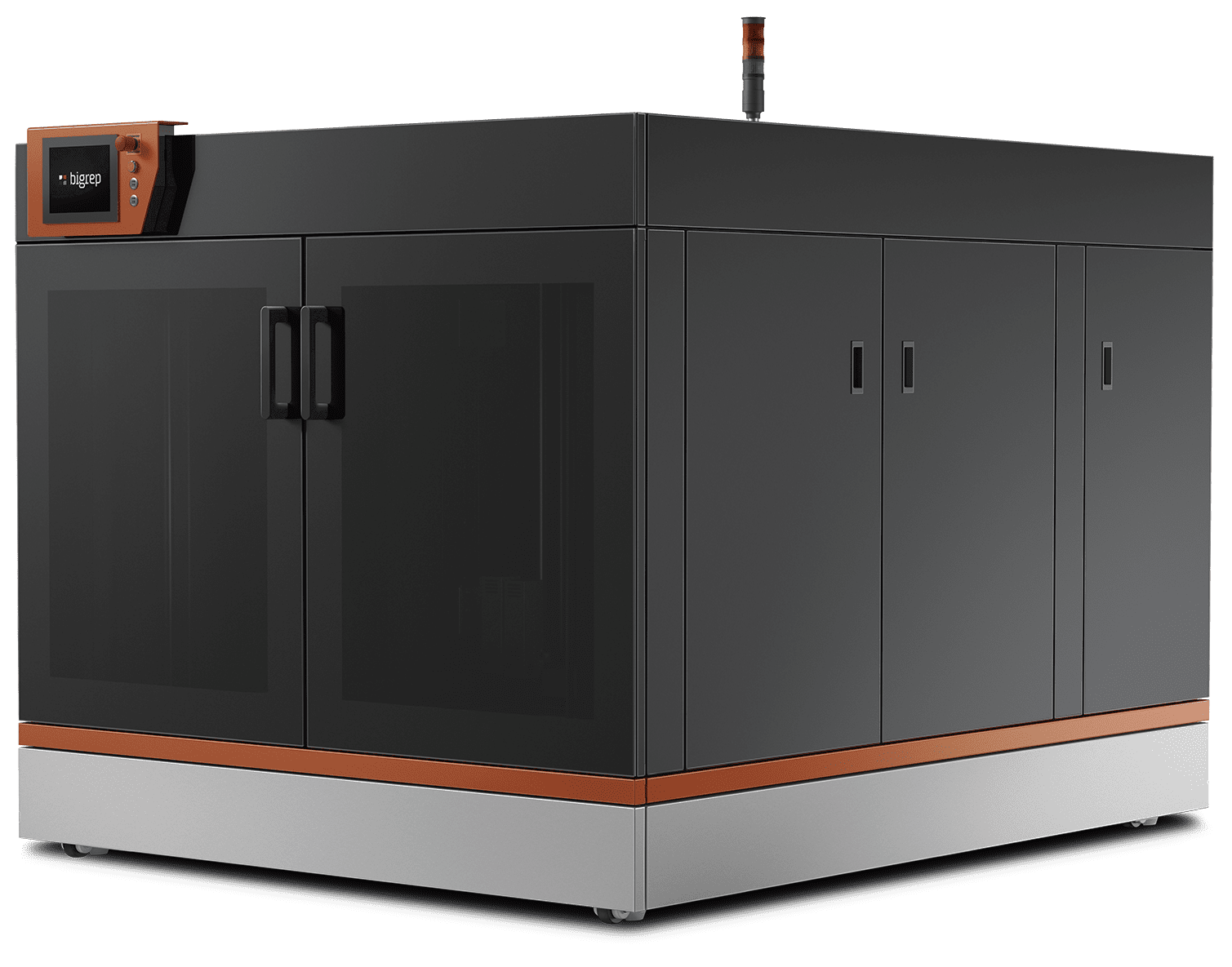

The BIGREP IPSO105 is an industry all-rounder high-temp machine at an unbeatable price-to-performance ratio.

With a 1 cubic meter build volume, the BigRep PRO is a fully enclosed industrial 3D printer for producing fullscale, large parts including functional prototypes, factory tooling, patterns and molds, and end-use parts.

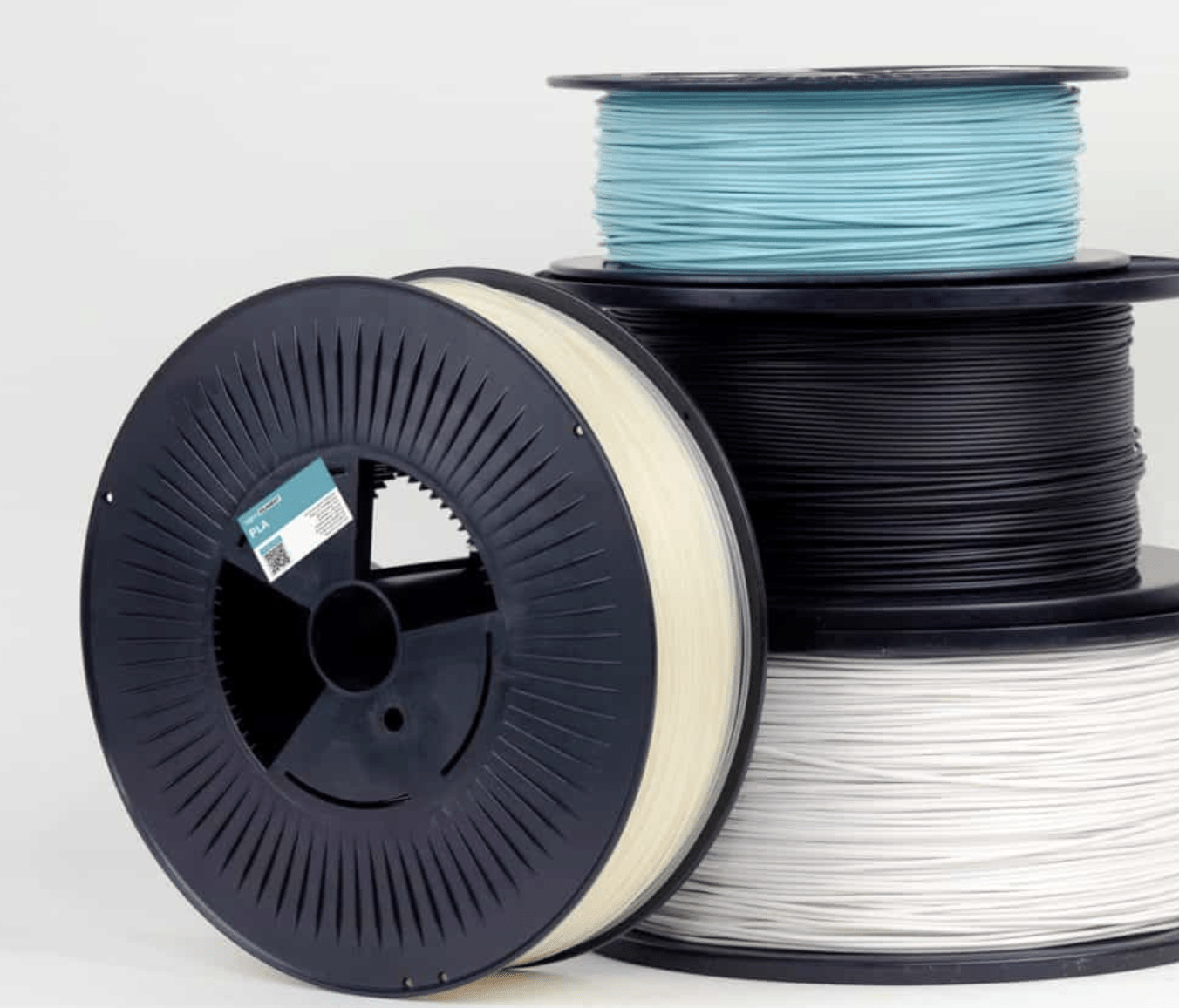

BigRep's portfolio of industrial 3D printer filaments are created under carefully controlled conditions to guarantee uniform diameter and consistent composition.

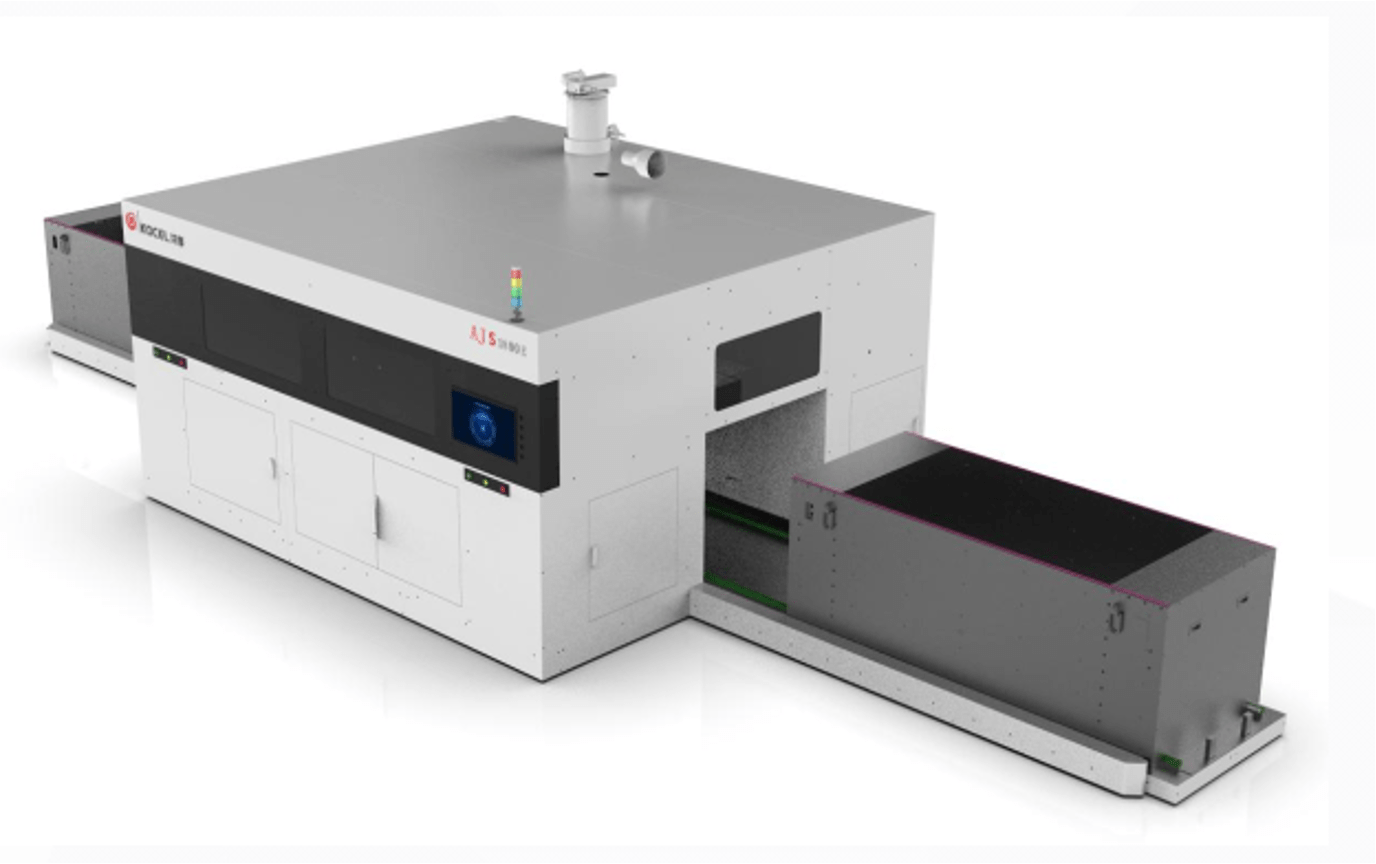

The AJS 1800B model is an industrial-grade 3D printing equipment with independent intellectual property rights developed by KOCEL Corporation.

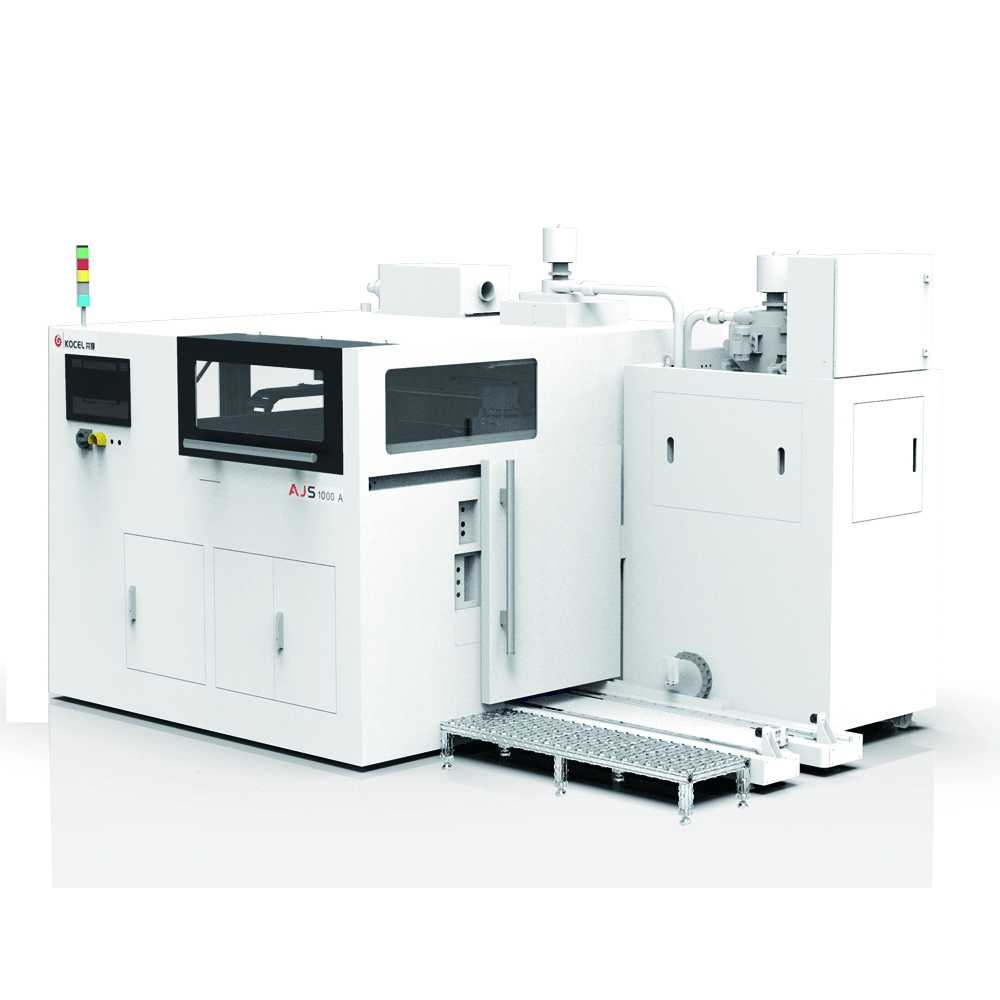

The AJS 800 is a sand mold 3D printer for industrial casting with independent intellectual property rights developed by KOCEL Corporation.

HOW TO CHOOSE THE RIGHT 3D PRINTING TECHNOLOGY FOR YOUR BUSINESS.

The diversity of 3D printing technology after a long path of development is shown most clearly in the article. Let's learn to see the importance and future of this technology.