Contactless 3d Inspection Service (3d Inspection).

Non-destructive 3D sample testing method

WHO USES THE NON-CONTACT 3D INSPECTION MEASUREMENT METHOD?

Casting and mold manufacturing industry.

Automobile and motorbike industry (All detailed parts and body shells…)

Aviation, aerospace (engines, turbines, plastic parts…)

Military (Military equipment)

Hydropower, oil and gas

For buildings and factories: 3d testing (3d testing) is intended to collect and store geometric profiles before they are damaged or deformed, ensuring correct technical specifications, structure and restoration features. Services for storage management, upgrading, repairing, replacing when damaged, destroyed or want to expand the structure based on the existing system

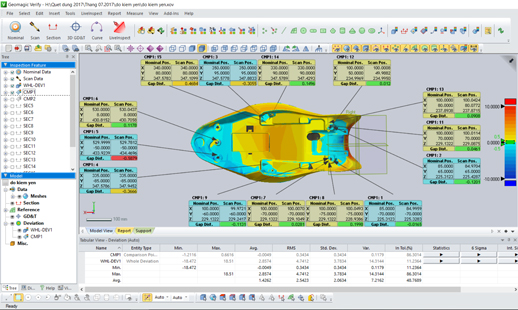

Non-contact 3d measurement of Turbine Blades using the 3d Scan method

Testing equipment: Handheld 3D Scanner system and Tscan CS probe set from Zeiss (Germany)

The color graph will analyze the results: Geometric errors, profile errors, defects or distortions between Turbine blades

PURPOSE OF NON-CONTACT 3D INSPECTION (3D INSPECTION)?

Today, with the continuous development of science and technology and great improvements in production, traditional measurement tools are not enough. It is difficult to meet the rigorous testing requirements for complex geometrical surfaces, irregular curved profiles or soft materials that are easily deformed.

Even if it takes a lot of time to measure, the accuracy is not high, it is difficult to operate, and the measurement results do not meet the manufacturer’s standards.

So what is the solution and alternative method?

Non-Contact 3D Measurement and Inspection technology using the 3d Scan method has effectively solved this problem and is gradually replacing traditional methods.

A wide range of industries are eager to gain access to non-contact 3D measurement applications as this 3D measurement process will help the network of manufacturers better meet strict time and time requirements. such as the comprehensive accuracy of product quality.

3-D data obtained as a point cloud is automatically matched with 2D drawing data to provide comparable results

WHAT IS 3D NON-CONTACT MEASUREMENT METHOD (3D INSPECTION)?

In the world, non-contact 3D testing using the 3D Scan method has been widely used. 3D Scanning equipment, in addition to copying 3D profiles for reverse engineering, creating molds, editing and changing designs, proportions, styles… Non-Contact 3D Testing is an application broad spectrum uses of this device.

Non-contact measurement using the 3D Scan method helps fully check all dimensions and surface profiles by scanning all or part of the object. The data obtained as a point cloud is automatically matched to the original CAD data or 2D drawing to provide comparable results.

All visual reports will be clearly displayed with color graphs for extremely accurate results. This non-contact 3D measurement method will accurately and quickly indicate geometric errors, profile errors, surface defects or abnormal deformations that traditional measurement methods cannot meet. .

Testing software allows creating repeatable formulas, automatically mass-testing similar parts based on the built-in trend analysis module to find variations in mass production .

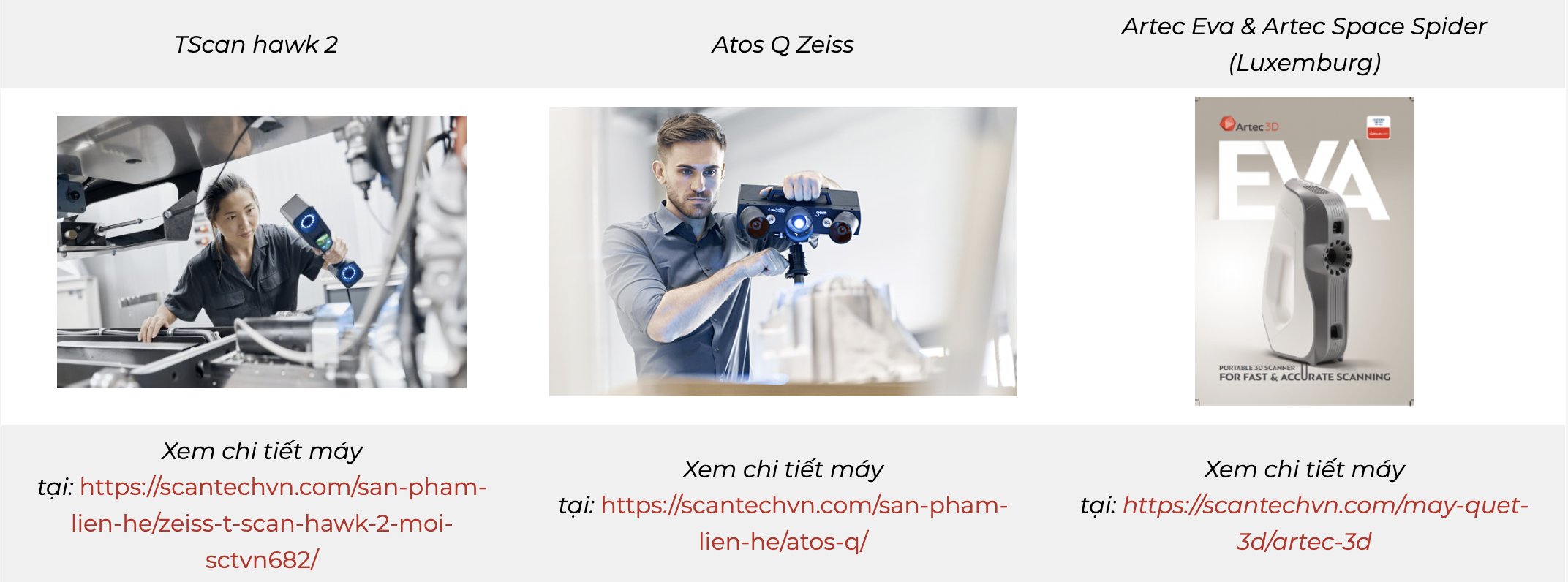

NON-CONTACT 3D INSPECTION (3D INSPECTION) USES WHAT EQUIPMENT?

Depending on each specific object and the accuracy level requirements to be measured, Scantech Vietnam

OTHER NEWS