3D printing has been on a steady path towards new challenges

Pressure creates diamonds – the way of 3D printing

Few can deny that additive manufacturing — commonly known as 3D printing — has undergone a development process filled with difficulties and challenges. But as specialized applications, a growing range of material options—and innovative experts—continue to develop, additive manufacturing is on a steady path toward challenges, alongside it is about being competitive on cost and throughput with traditional manufacturing processes.

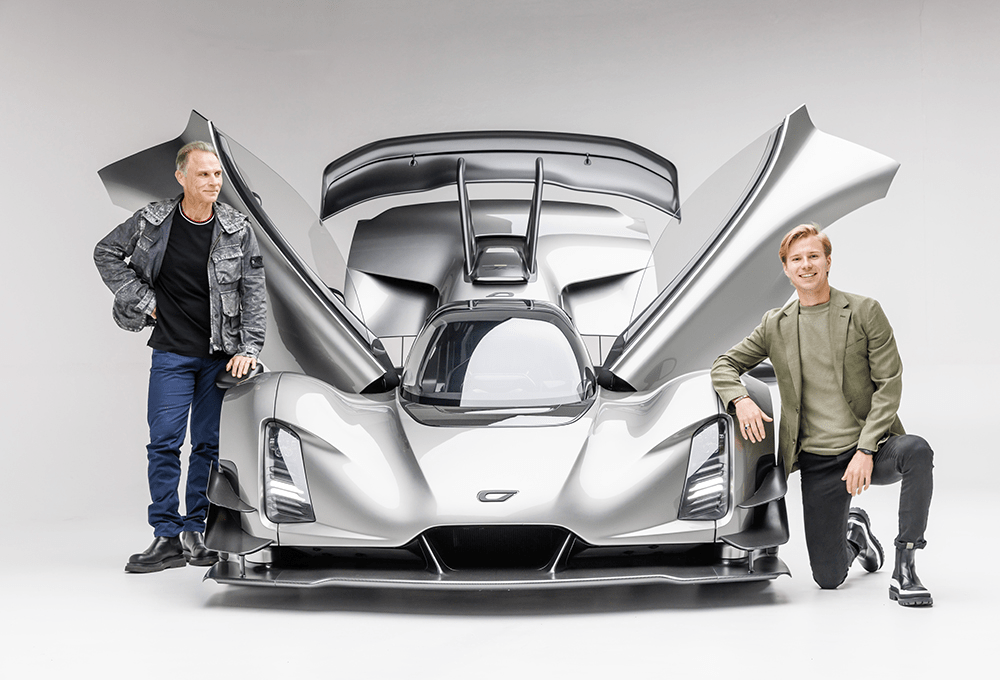

Automotive Engineering recently spoke with two major advocates of 3D printing technology, Divergent/Czinger 21C of Los Angeles and 3D Systems, based in Rock Hill, South Carolina. Each unit is implementing a unique strategy to explore and advance the future of additive manufacturing.

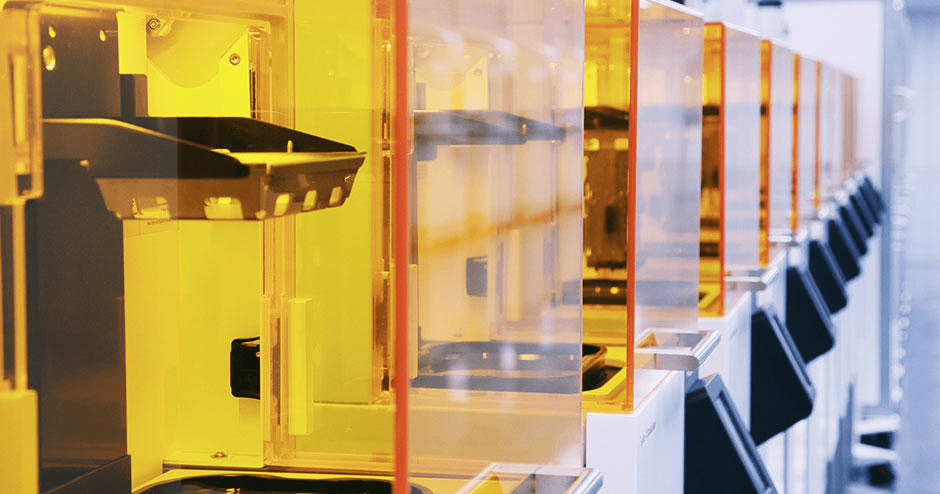

The Divergent Adaptive Manufacturing System (DAPS) is a complete hardware-software solution designed to replace traditional vehicle manufacturing. It is essentially a complete modular digital factory for complex structures. With a set of digital requirements, DAPS automatically calculates design, manufacture and retrofit any complex structure. The system can switch seamlessly between the production of different vehicle models.

DAPS uses AI generation and 3D modeling in the design process. Using additive manufacturing, Divergent can print complex geometries and lighter parts and assemblies. DAPS eliminates molding and stamping and uses bonding instead of welding. It also eliminates the need for jigs during assembly.

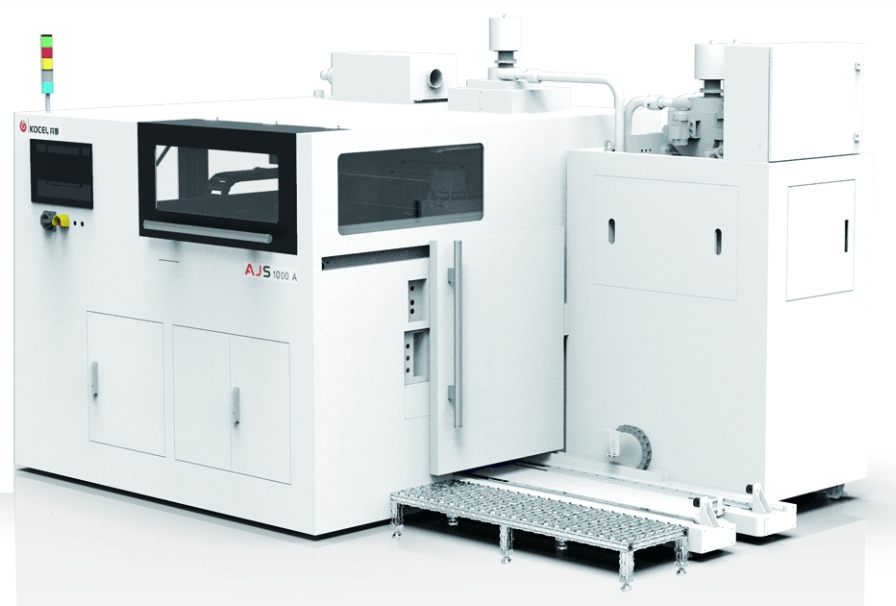

3D Systems takes a different approach – the company is a one-stop shop for “all things additive.”

Meanwhile, 3D Systems takes a different approach – the company is a one-stop shop for “everything related to additives.” The company is not only a supplier of materials, software, hardware and services but also a primary user. 3D Systems says, “ We push the boundaries with consulting and expert additive manufacturing solutions that improve existing things and make new things happen.”

In the automotive sector, 3D Systems touts 58% lower development costs for mission-critical systems and 10x acceleration of product development projects. According to Pat Warner, director of advanced digital manufacturing at the Alpine Formula One team, “It has been exciting to co-develop [with 3D Systems] the Accura Composite PIV and see the benefits it brings to our processes”.

Particle Image Velocimetry (PIV) is a non-invasive optical flow measurement technique used to study fluid flow patterns and velocities. 3D Systems’ Accura Composite PIV is a new material specifically designed to address PIV testing applications primarily used in motor sport wind tunnel testing. Accura Composite PIV can produce rigid parts with high contrast colors optimized for PIV testing.

THANK YOU CUSTOMERS AND PARTNERS FOR ALWAYS TRUSTING AND ACCOMPANYING US

SCANTECH VIETNAM COMPANY

Address: BT6-30 Diplomatic Corps, Xuan Tao Ward, Bac Tu Liem District, Hanoi

Hot.line: 0862170366

Email: contact@scantechvn.com / kdscantech@gmail.com

Fanpage: https://www.facebook.com/scantechvn

OTHER NEWS