Scantech 3D - Official authorized dealer in Vietnam

TECHNOLOGY & PRODUCT

5 "INCREDIBLE" EFFECTS FROM 7 3D PRINTING TECHNOLOGIES:

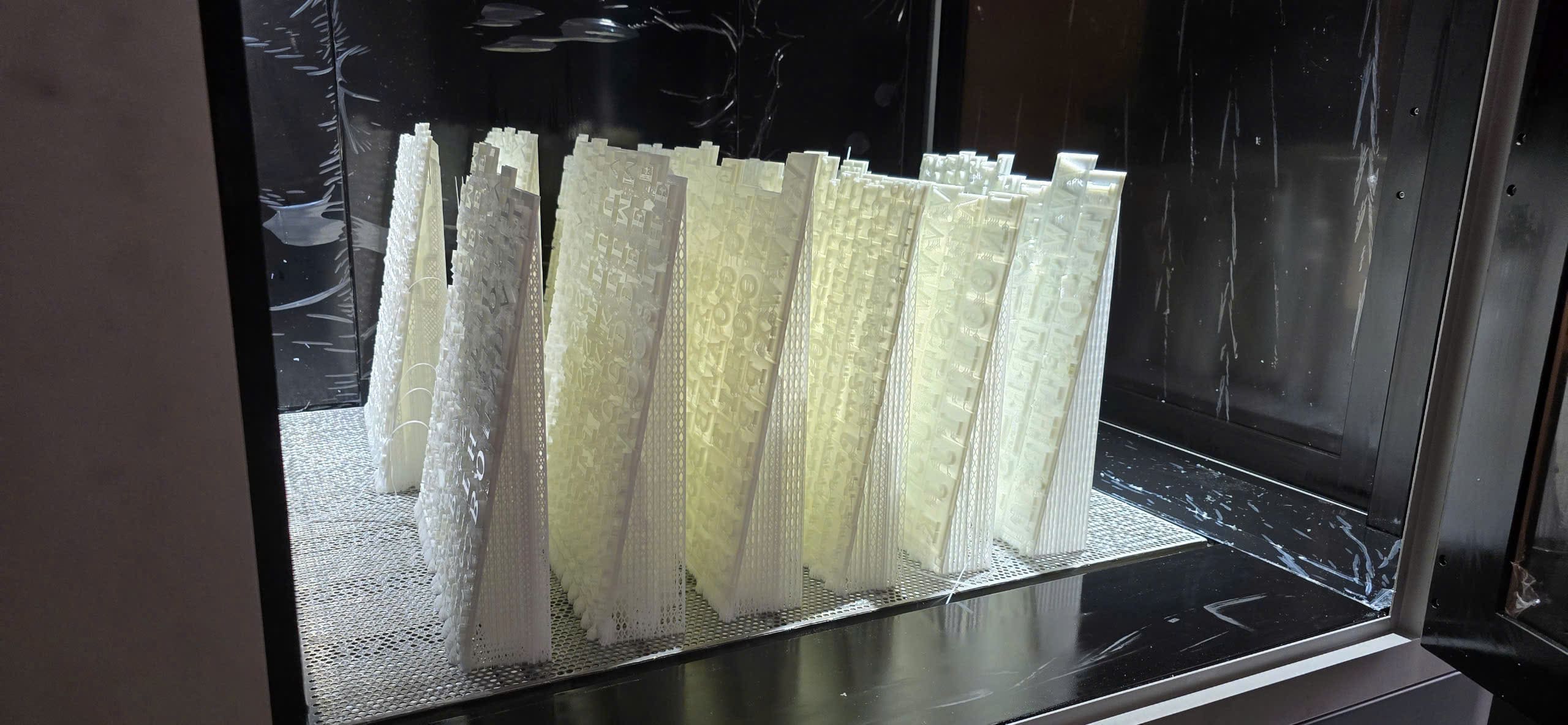

- Create perfectly functional 3D Printed models, meeting all the most stringent international standards on: Material mechanical properties, accuracy level, printed layer smoothness and durability. difficulty of printing model.

- Shorten Design time, speed up innovation and New Product Development.

- Completely eliminate all costs for traditional mold prototyping.

- Save time, labor costs, risk costs.

- Huge competitive opportunity for businesses to prove their production capacity, improve quality and reduce product costs.

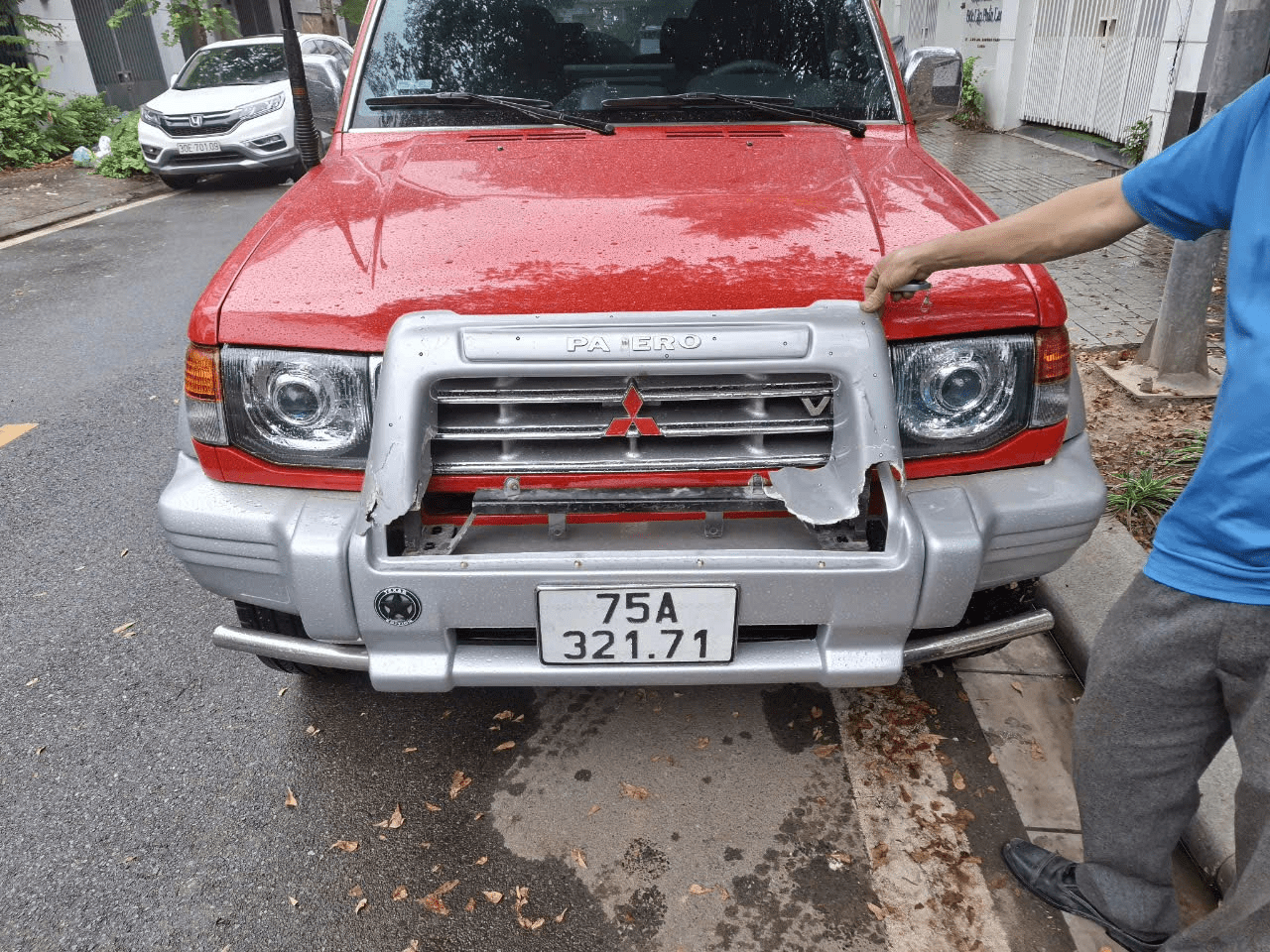

- 3D Scanning Technology is widely applied in many different industries: such as automobiles, aerospace, dentistry, jewelry, molds, etc. Especially in the field of research and development of new products, 3D technology helps designers take shortcuts, shorten the time to improve designs, and increase accuracy.

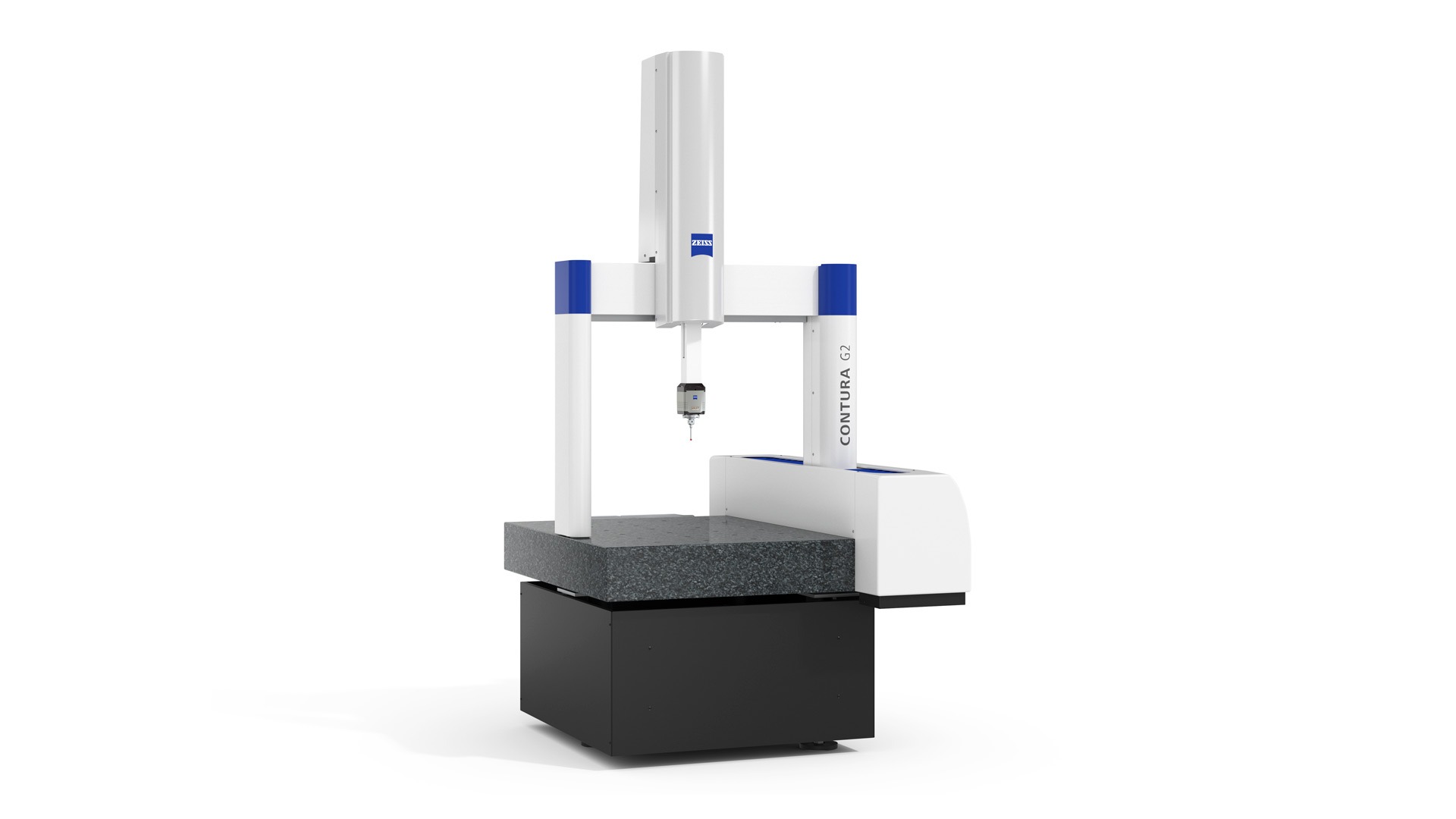

- 3D Measurement technology allows control, intervention and quality improvement in all product manufacturing processes. 3D inspection today has become the optimal tool and the gold standard to evaluate the quality and capacity of tool and mold manufacturers as well as for precision component manufacturers.

- 3D Scanning & 3D Measurement devices from big brands like ZEISS (GOM)... will help manufacturers completely replace traditional methods, helping to save maximum time, labor and investment costs. Increase production and demonstrate leading capacity in the market.

- In all measurement tasks, measurement strategy is important. Choosing which measurement method will depend on the purpose of measurement, structure and material of the product to be measured, and then choosing the measuring device. Sometimes it will be necessary to combine 2 or more measurement methods to get the best results. Once a good practice has been developed for a common part type, it becomes much easier to duplicate the process and implementation.

- Carl Zeiss is a pioneer in the field of multi-dimensional measurement in the laboratory and metrology for manufacturing. Carl Zeiss is a recognized partner of the automotive industry and its suppliers with 2,400 production sites in 40 countries and more than 100 sales and service centers providing customers around the world.

- Carl Zeiss ensures industrial measurement quality at the most effective cost.

TOP MOST SELECTED 3D DEVICES

Industry-leading ultra-high resolution handheld 3D scanner

The T-SCAN hawk 2 is the first handheld laser scanner with a "satellite" scanning mode that can scan very large volume objects without using an integrated imaging method with marked markers. encode.

Uses a dual nozzle system optimized for both speed and accuracy. High heat-resistant steel nozzle allows printing a variety of plastic materials with different melting temperatures

ATOS Q was developed for industrial applications to provide highly accurate 3D data in short measurement times creating traceable measurement results – even in harsh measuring conditions

ProJet® MJP 2500W Plus 3D Prints in VisiJet® 100% Wax to create durable, high-quality jewelry pieces that deliver reliable performance and results throughout unused casting processes and equipment Use existing wax.

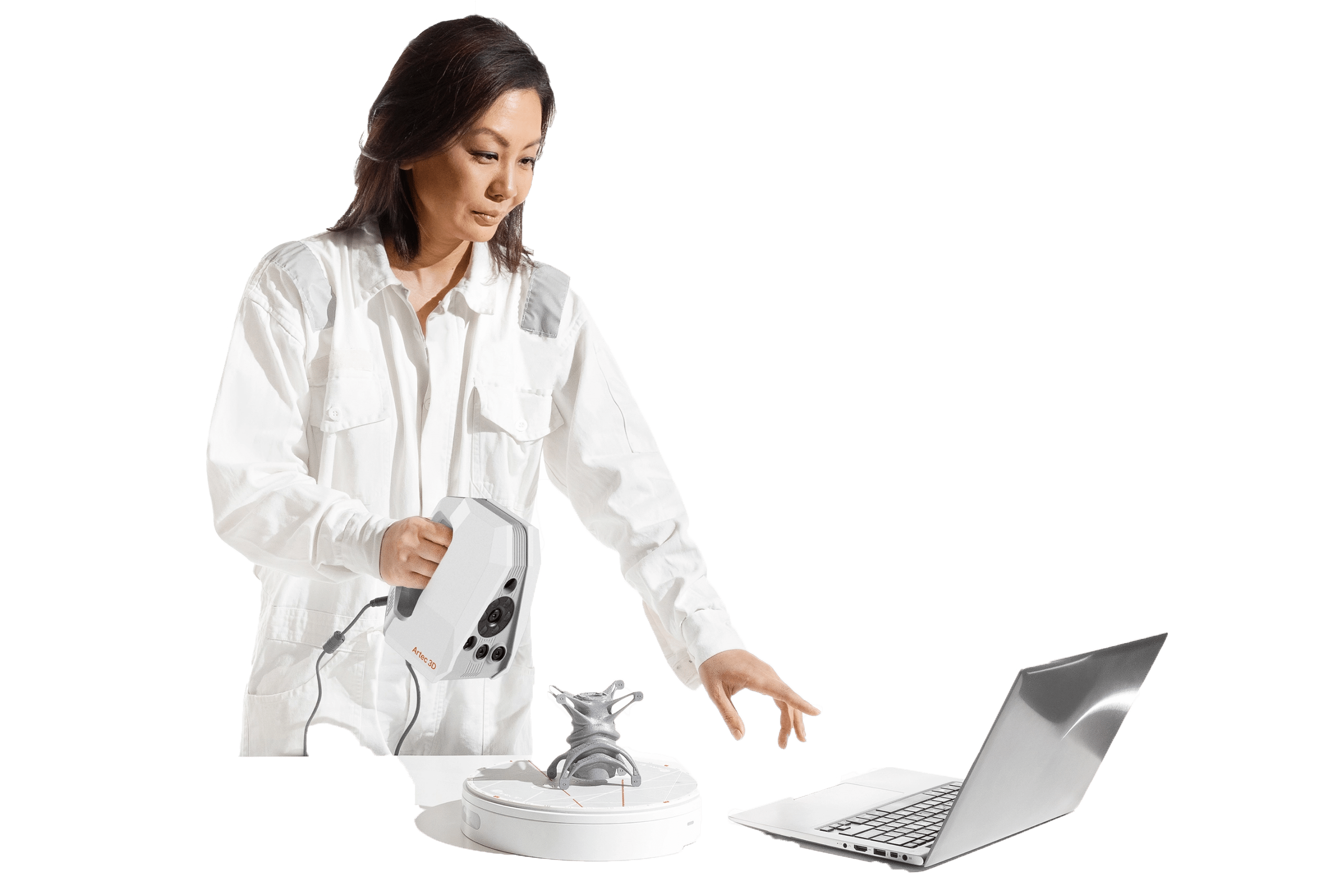

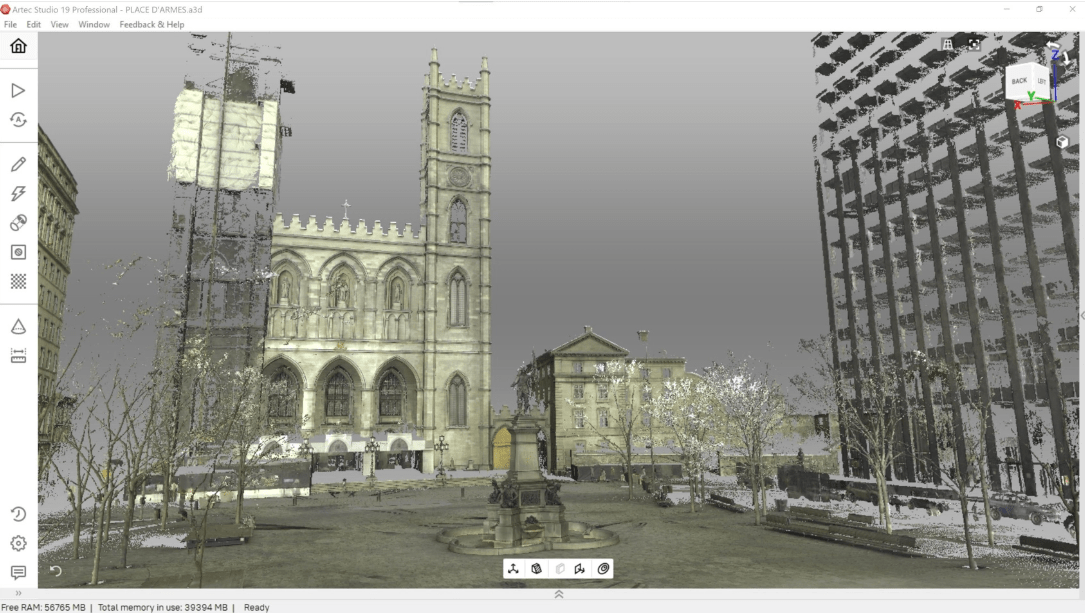

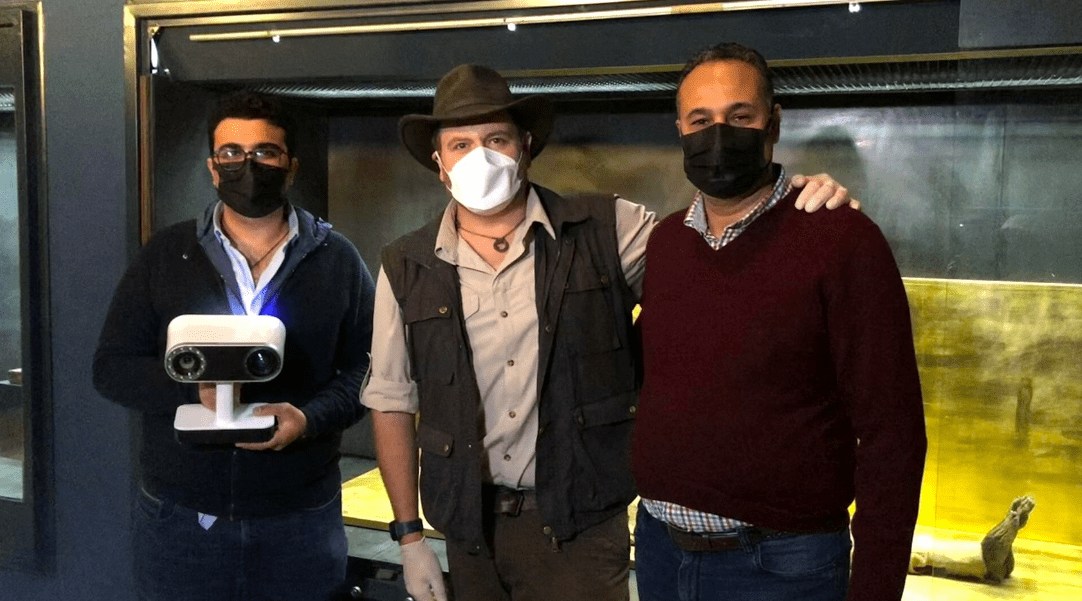

Artec’s first target-based 3D laser scanner puts ISO-certified, metrology-grade 3D scanning in the palm of your hand. Artec Point rapidly captures complex surfaces – even those featuring black or shiny exteriors – with up to 0.02 mm accuracy for quality control and reverse engineering.

SERVICE

APPLICATION

Providing 4.0 technology solutions in a variety of fields from Health, Science, Security, Defense, Arts, Entertainment,... We understand that the development of Scanning and 3D printing technology will increasingly develop in important fields of the world. gender.

NEWS

LIBRARY

Collection of designs and products that we have used a lot of enthusiasm and expertise to create. Collection of designs and products that we have used a lot of enthusiasm and expertise to create. Each product goes through a professional and thorough scanning and editing process from our team of engineers.