Vinh Ha hydroelectric plant

This is the second lowest water head hydroelectric project in the North after ICT Chiem Hoa Hydroelectric Plant, Tuyen Quang province, invested and built by ICT Company, using bulb-type direct-flow turbine technology. This technology is currently being used in many advanced countries around the world.

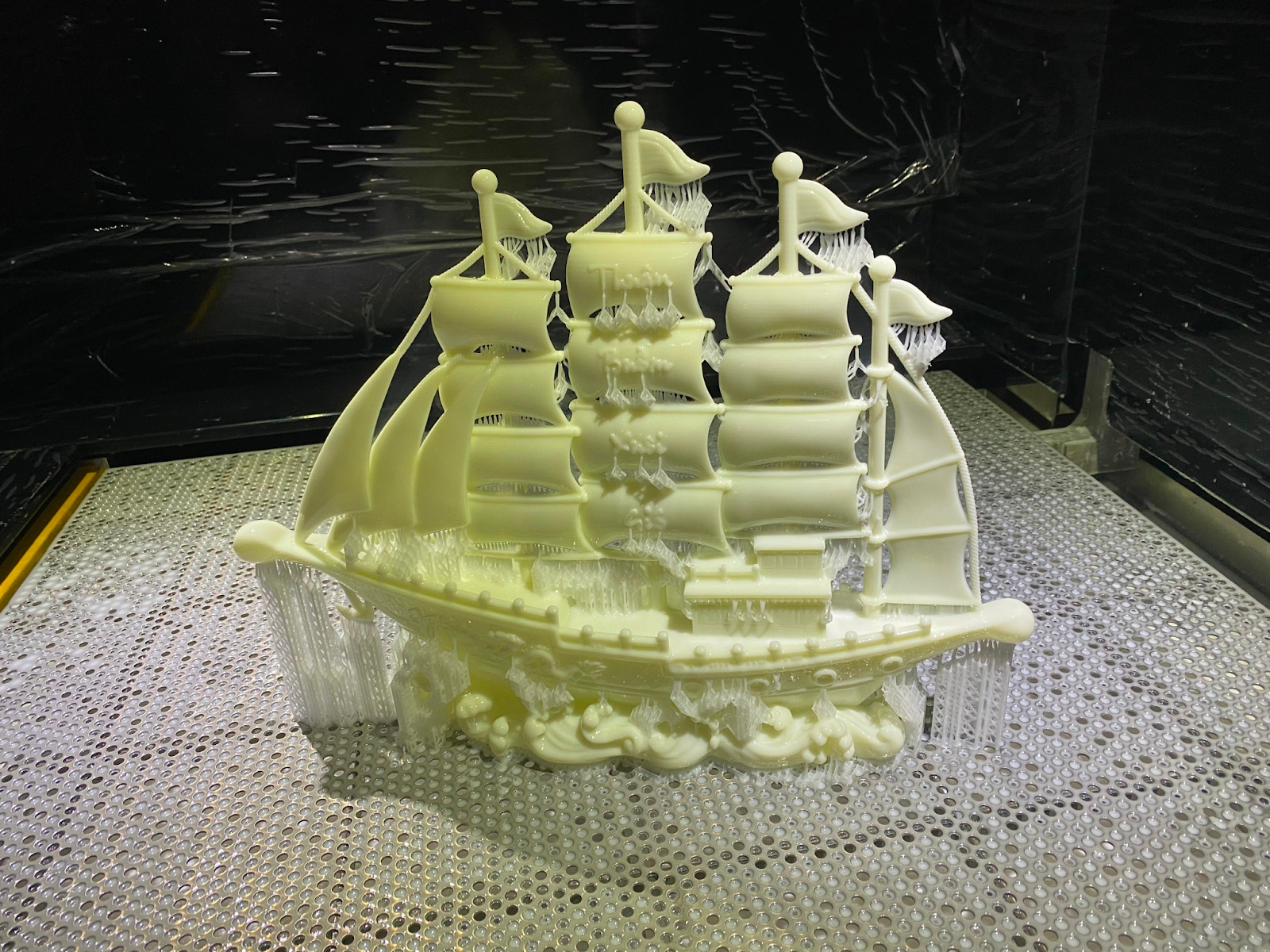

To ensure accuracy for turbine blades / impellers, solutions focus on the application of non-contact 3D measurement technology using the 3D Scan method, allowing inspection of entire surfaces and curved profiles. , volume, area… quickly provide optimal solutions for production.

This is the most modern and advanced solution to date and will explode strongly in the future because of its very high accuracy, saving 90% of time, labor and costs.

Using 3d Tscan scanner from Zeiss (Germany) with accuracy level (0.01-0.05mm) for measurement

Because the size of the turbine blades is quite large and requires high precision, the factory had quite a hard time finding implementation partners. Because most 3D Scanner models in Vietnam today do not meet the factory’s requirements. 3D Scanners with high accuracy levels can only scan small and medium profiles. 3D scanners that can scan large models like Thor and Shining have an error of 0.1-0.5mm. And luckily, the factory came to Scantech Vietnam Company with Tscan 3d scanner equipment from Zeiss (Germany) with an error of 0.01-0.05mm.

Non-contact 3D measurement using 3D Scan method

The testing process only takes place within 1 working day, the testing parameters are sent immediately to the customer, meeting the factory’s time and schedule.

On behalf of Scantech Vietnam Joint Stock Company, we would like to thank the factory Board of Directors for their trust and choice. Scantech Vietnam will continue to make further efforts to meet all factory requirements.

TIN TỨC KHÁC