Plastic 3D Printing – Accelerating Product Innovation

In modern industrial product development, plastic 3D printing helps businesses shorten the testing phase — turning ideas into physical prototypes within hours.

Without investing in expensive molds, companies can still verify design, assembly, and functionality before moving into mass production.

Scantech VN provides high-precision plastic 3D printing services, from simple design prototypes to complex technical models, meeting industrial, R&D, medical, and educational standards.

Applications of Plastic 3D Printing Across Industries

Product Design & R&D

Plastic 3D printing is an essential tool for R&D teams aiming to accelerate concept validation and easily adjust designs based on real-world feedback — without mold-related costs.

-

Create prototypes within 1–2 days.

-

Test assembly fit and mechanical function before production.

-

Simulate complex geometries that are difficult to achieve with traditional machining.

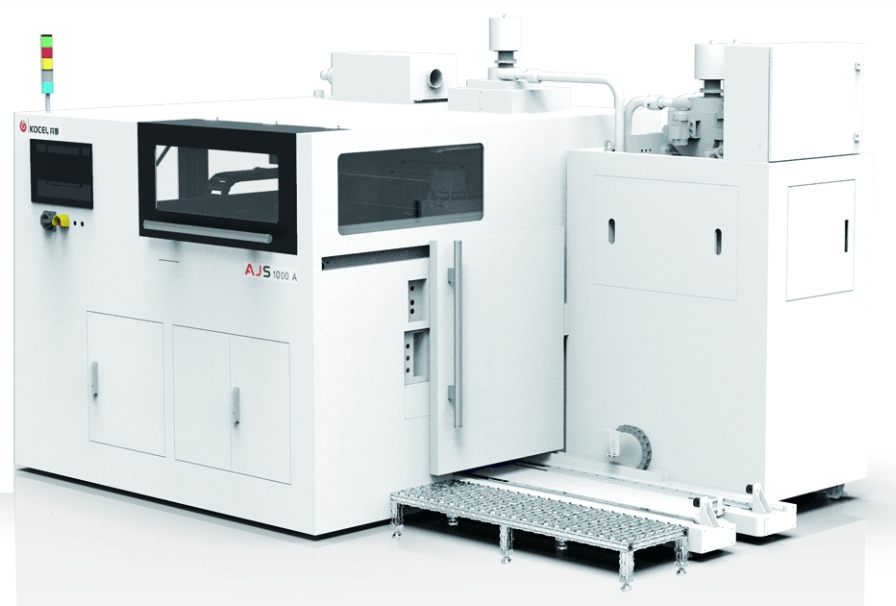

Mechanical & Industrial Manufacturing

With high durability and precision, industrial-grade plastic 3D printing is used to:

-

Produce custom jigs, fixtures, and supports for production lines.

-

Print lightweight, complex technical parts that are hard to machine via CNC.

-

Create temporary molds for plastic, silicone, or composite casting.

💡 Result: Reduce fixture production time by up to 70% and cut R&D costs by up to 50%.

Medical & Dental Applications

Scantech VN’s optical resin printing technology enables:

-

Anatomical models and surgical planning prototypes.

-

Dental models, aligner trays, and high-precision restorations.

-

Custom surgical tools tailored to individual patients.

All bio-compatible resins used by Scantech VN meet medical safety and material stability standards, ensuring quality and reliability in biomedical applications.

Education & Technical Training

Universities and research institutes are increasingly adopting plastic 3D printing to:

-

Demonstrate mechanical and design principles in class.

-

Print educational models and functional teaching tools.

-

Prototype and test student innovations and experimental projects.

3D Printing Materials – Versatile and Application-Specific

Scantech VN offers a wide range of printing materials, including:

-

Standard resin: for fast prototypes.

-

Heat- and impact-resistant resin: for functional mechanical parts.

-

Transparent or bio-resin: for medical and aesthetic applications.

-

PLA, ABS, PETG, Nylon: for large-format FDM printing.

Each material is selected based on your project’s practical goals — ensuring cost efficiency and optimal performance.

Key Benefits of Partnering with Scantech VN

✅ Professional consultation on the right technology and materials for each application.

✅ Fast, accurate, and confidential model processing.

✅ Expert post-processing: sanding, painting, polishing, and coloring.

✅ Cost optimization for small-batch production, prototyping, or pre-series testing.

Scantech VN – A Trusted Partner in Your Creative Journey

From startups to large-scale manufacturers, Scantech VN stands as a reliable partner in turning concepts into tangible products.

With advanced technology, experienced engineers, and flexible services, Scantech VN delivers professional, precise, and sustainable plastic 3D printing solutions for modern enterprises.

🔗 Explore more: Comprehensive 3D Printing Solutions by Scantech VN

🔗 Learn more: 3D Printing Technologies

📞 Hotline: 0904 985 139 / 0862 170 366

📧 Email: ktscantech@gmail.com

🌐 Website: scantechvn.com

📘 Facebook: facebook.com/scantechvn

🏢 Showroom: BT6-30 Ngoai Giao Doan, Xuan Dinh Ward, Hanoi

OTHER NEWS