Industrial FDM 3D Printer – Accelerating the Production of Jigs and Trial Assembly Molds

Scantech has completed the inspection and delivery of a KING 3D Printing brand industrial FDM 3D printer to a manufacturer specializing in automotive and motorcycle parts in Dong Nai, Vietnam. This machine is optimized for directly printing various jigs, assembly fixtures, and inspection tools for immediate use on production lines, significantly reducing time and costs compared to traditional machining methods.

KING FDM printers are imported for testing

Scantech – Importing, Inspecting, Operating, and Delivering

The KING FDM printer is officially imported by Scantech. It undergoes a strict inspection and trial operation process before being delivered. This is a standardized procedure to ensure every machine reaches the customer in optimal condition.

1. Thorough Inspection After Unboxing

Immediately upon import, Scantech’s technical team performed a comprehensive inspection of the KING FDM printer. Trial runs were conducted in a simulated production environment under standard operating conditions to verify the machine’s stability and smooth functionality.

Inspection steps include:

-

Checking the drive system and print head

-

Calibrating the print bed and measuring mechanical accuracy

-

Testing heating capability and temperature stability

-

Verifying the X-Y-Z axis accuracy during movement

-

Ensuring all accessories meet the manufacturer’s standards

Conduct a comprehensive inspection of KING’s FDM printer

2. Test Runs and Real-World Sample Printing

Technical Inspection Before Delivery

2.1. Mechanical Check – Ensuring Stable Operation

Once the KING printer arrived, Scantech engineers carried out:

-

Inspection of the drive system and X-Y-Z axis precision

-

Print bed leveling and full-area flatness verification

-

Evaluation of heating capability and continuous printing stability

-

Ensuring all accessories meet manufacturer’s technical standards

2.2. Test Printing a Real Jig Sample

The customer provided a 3D design file, and Scantech printed a test jig with the following features:

-

Two-part mold jig with four assembly points

-

Solid structure with curved contact surfaces

-

Bolt positioning holes and through-shaft openings

-

Lightweight structure suitable for conveyor line support

-

Moderate precision required for fitting with actual parts

-

Print material: PLA – high rigidity, stable heat resistance, suitable for real-world use

Conduct test runs and print actual test samples

2.3. Test Print Results and Final Evaluation

✔️ Smooth print surface, no warping, components fit as per design

✔️ Flat contact points – no need for post-processing

✔️ Structure is strong enough to support actual parts

✔️ Printed jig was immediately used for testing in the production line – fully functional

🎯 No need to wait for CNC machining – no aluminum mold prototyping – use 3D printed parts directly on the production line!

|

|

|

|

|

|

|

Test print and assembly results

The overall assessment showed the KING FDM printer meets all technical requirements and is fully ready for real-world deployment at the client’s facility.

✅ Advantages of FDM Technology for Industrial Jig Printing

💸 1. Low Cost – High Efficiency – Affordable Materials

FDM materials (like PLA, ABS, PETG, Nylon…) are much cheaper than CNC-machined metal or engineering plastics.

Great cost savings for test jigs, temporary jigs, or frequent design changes.

⏱️ 2. Fast Production Speed

Design in the morning, print by the afternoon, mount on the line in the evening 😎

Cuts production time from several days (traditional machining) to just a few hours.

🧩 3. Print Complex Jig Structures

Capable of printing hollow, lightweight, multi-layered, or multifunctional designs (holding, gripping, inspecting) in a single part.

Not limited by molds or cutting tools.

🧪 4. Flexible Material Options

-

ABS: Heat and impact resistant – ideal for load-bearing jigs

-

PETG: Durable, warp-resistant – ideal for outdoor fixtures

-

Nylon (PA): Abrasion resistant – for jigs with moving parts

-

TPU: Flexible – anti-slip or cushioning elements

Also available: Carbon fiber or GF-reinforced filaments for ultra-durable jigs 💪

🔄 5. Easy Design Modification – No Need to Start Over

If part dimensions change, just update the CAD file and reprint.

No need to reprogram CNC or make new molds.

🏭 6. Suitable for Diverse Product Lines – Various Sizes

Quickly print individual parts and change designs frequently – perfect for workshops with multiple product lines.

Reduces external dependency, gives full control over in-house jig production.

🧼 7. Clean, Lightweight, and Easy to Use Jigs

Lighter than metal jigs → reduces manual handling risks

Easy to clean, less oil and dust accumulation compared to traditional CNC jigs

🚀 Scantech – A Trusted Partner for Manufacturing Enterprises

If your business is looking for a reliable industrial FDM 3D printer, let Scantech support you with:

✅ Consultation to choose the right equipment for your needs

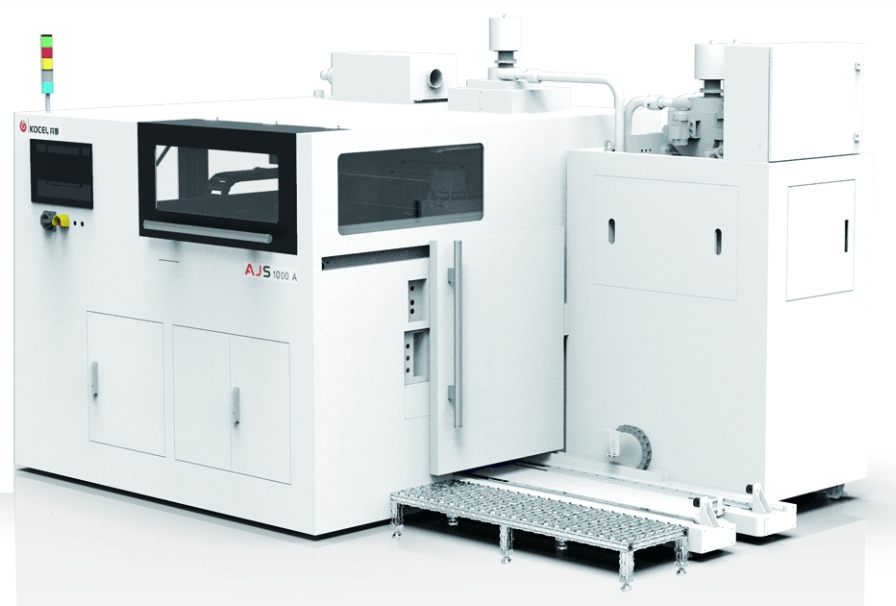

✅ Supply of high-quality 3D printers from top brands like KING, 3D SYSTEMS, BIGREP, and KOCEL

✅ Commitment to transparent inspection, test printing, and industrial-standard delivery

📩 Request a Quote & Get Expert 3D Printing Advice Today

Let Scantech be your companion in optimizing production, shortening prototyping time, and improving technical precision.

📞 Hotline: 0904985139

📧 Email: kdscantech@gmail.com

🌐 Website: https://scantechvn.com

📍 Fill out the quick consultation form on our website to be contacted by a Scantech engineer within 24 hours!

OTHER NEWS