SAND MOLD 3D PRINTER FOR CASTING-KOCEL AJS 800

Specifications

Molding Size(mm)

800×500×400

Printer Size(mm)

3700×2500×2250

Nozzle resolution(DPI)

400

Printing efficiency (L/h)

18-45

Printer weight(t)

5

Layer thickness(mm)

0.2-0.5

Printing accuracy(mm)

±0.25

Materials

Silic sand etc.

Product Description

MANUFACTURER: KOCEL GROUP

INTRODUCTION OF KOCEL GROUP

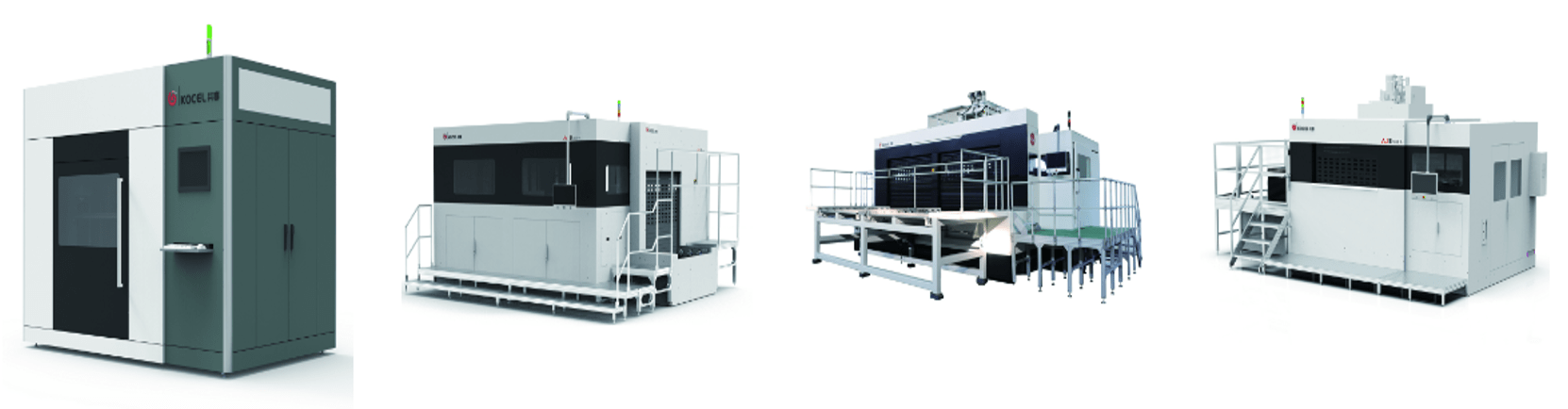

KOCEL Group started researching and developing sand mold 3D printers for casting in 2012. After more than 10 years, from the first functional prototype to now, it has developed 15 models of 3D printing equipment.

The equipment includes large, medium and small models, which can be applied to educational and scientific research institutes, large, medium and small casting enterprises, mold manufacturing enterprises and other fields.

The printing performance, stability, precision and intelligence of the equipment have reached or exceeded the technical level of similar equipment abroad, promoting the company’s intelligent manufacturing and upgrading transformation path, and promoting the transformation of China’s casting industry.

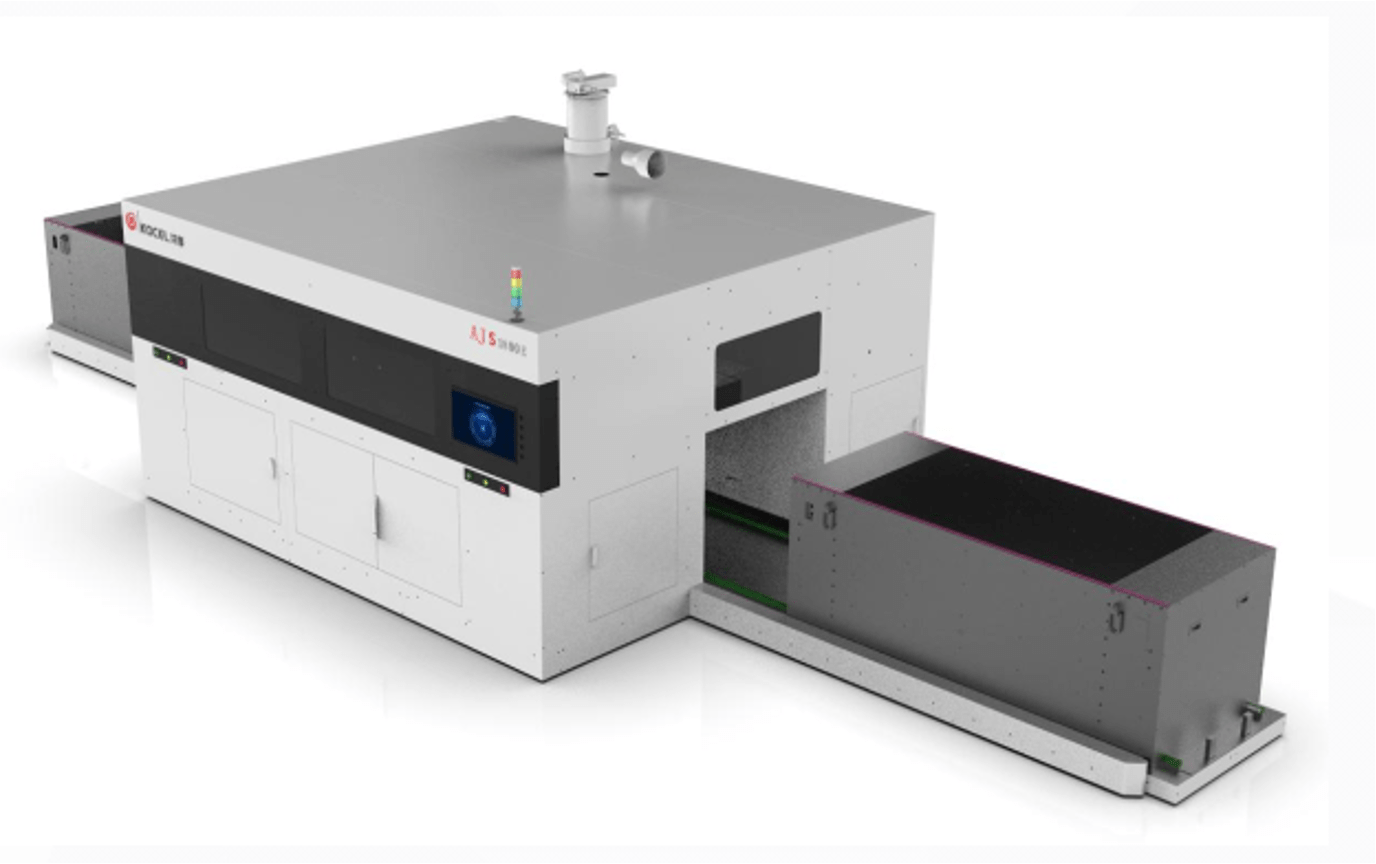

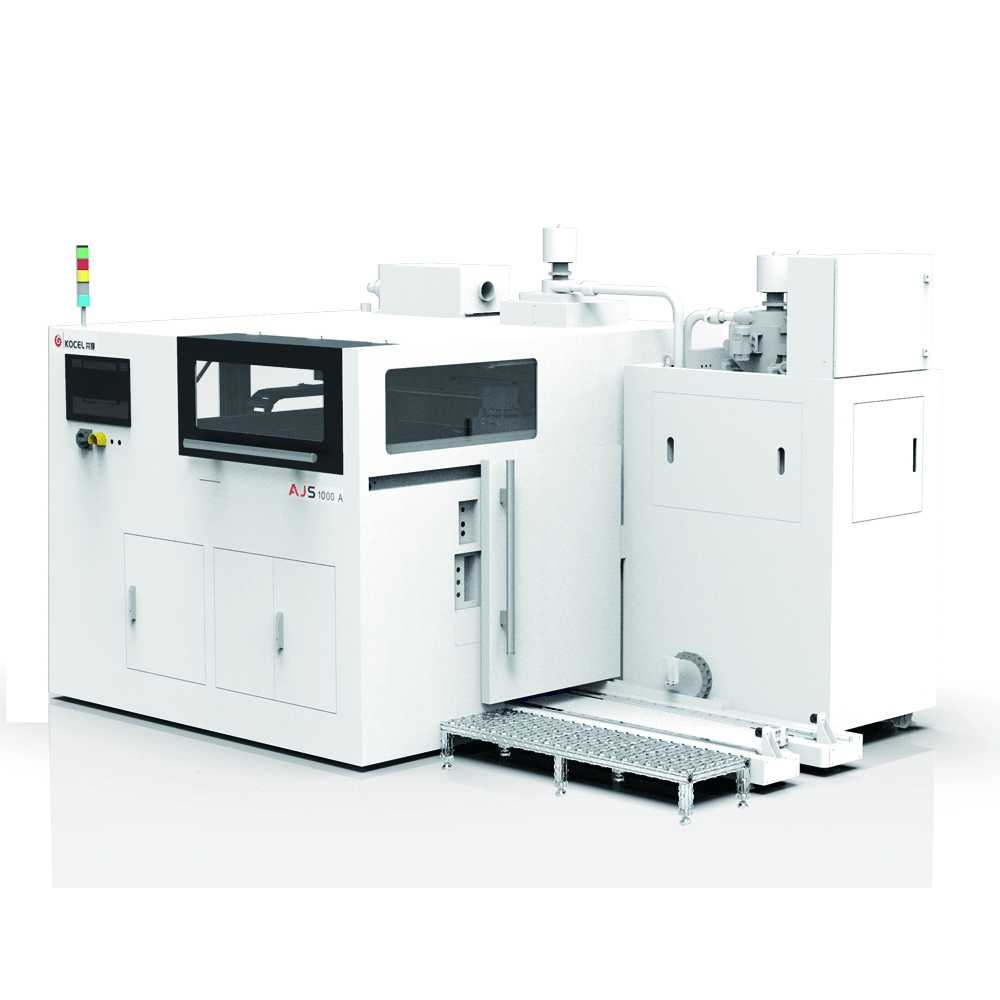

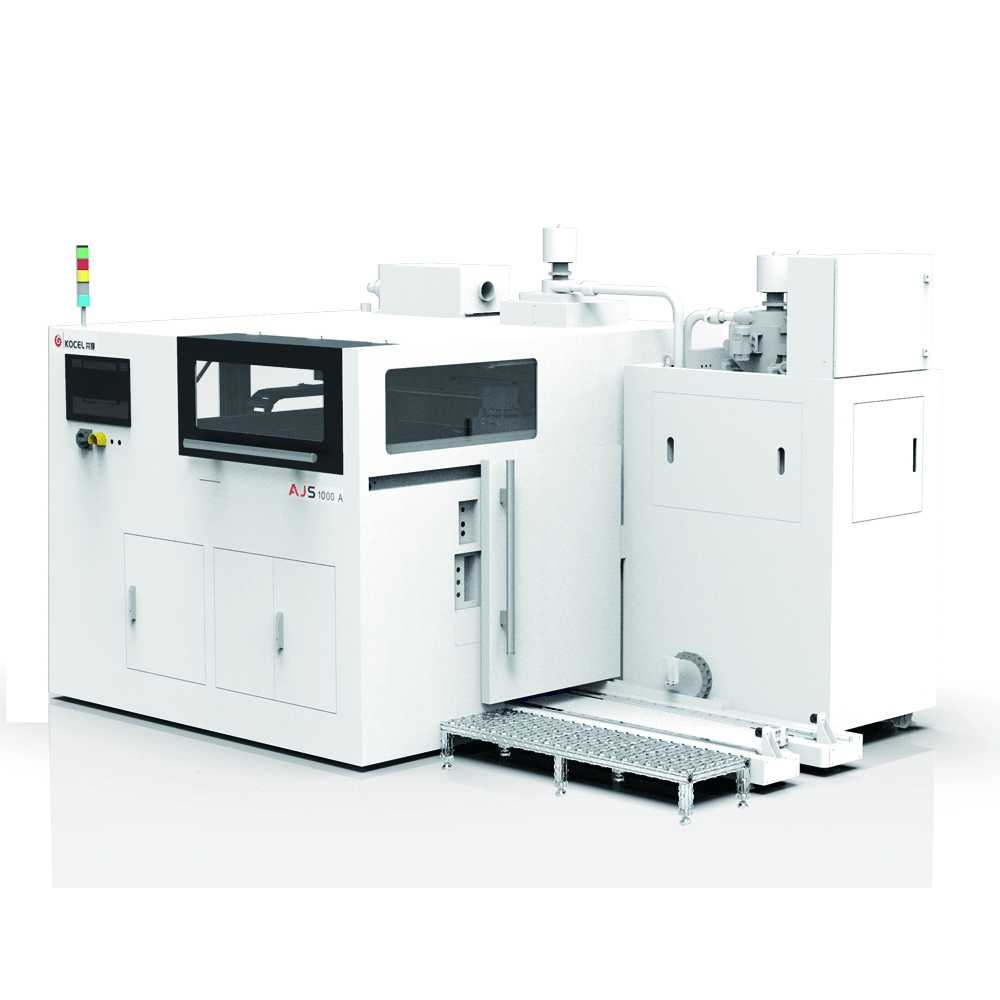

INTRODUCTION TO KOCEL AJS 800 3D PRINTER MODEL

The AJS 800 is a sand mold 3D printer for industrial casting with independent intellectual property rights developed by KOCEL Corporation.

The machine uses sand as the main material combined with binder to print sand molds with complex structures and high precision by applying the 3DP principle.

The equipment is characterized by high printing efficiency, excellent quality and low cost, suitable for industrial production applications of various sands.

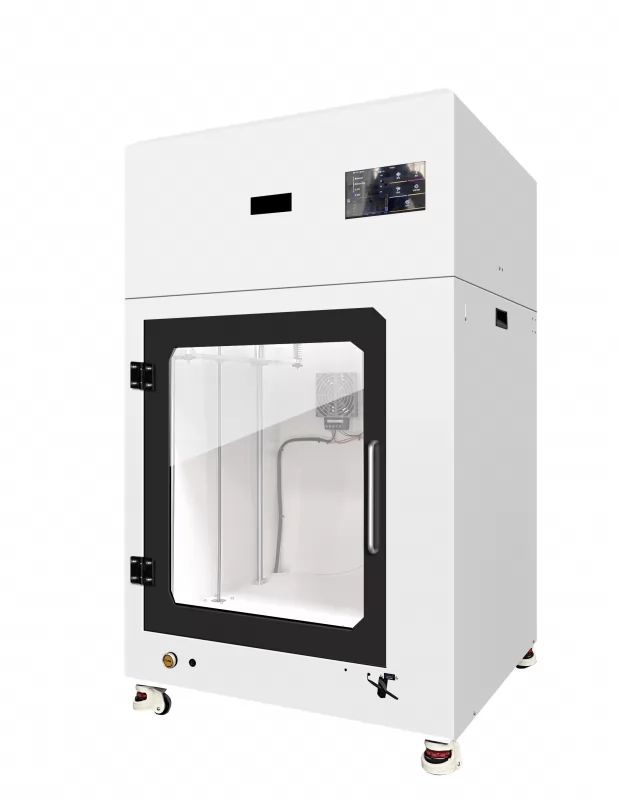

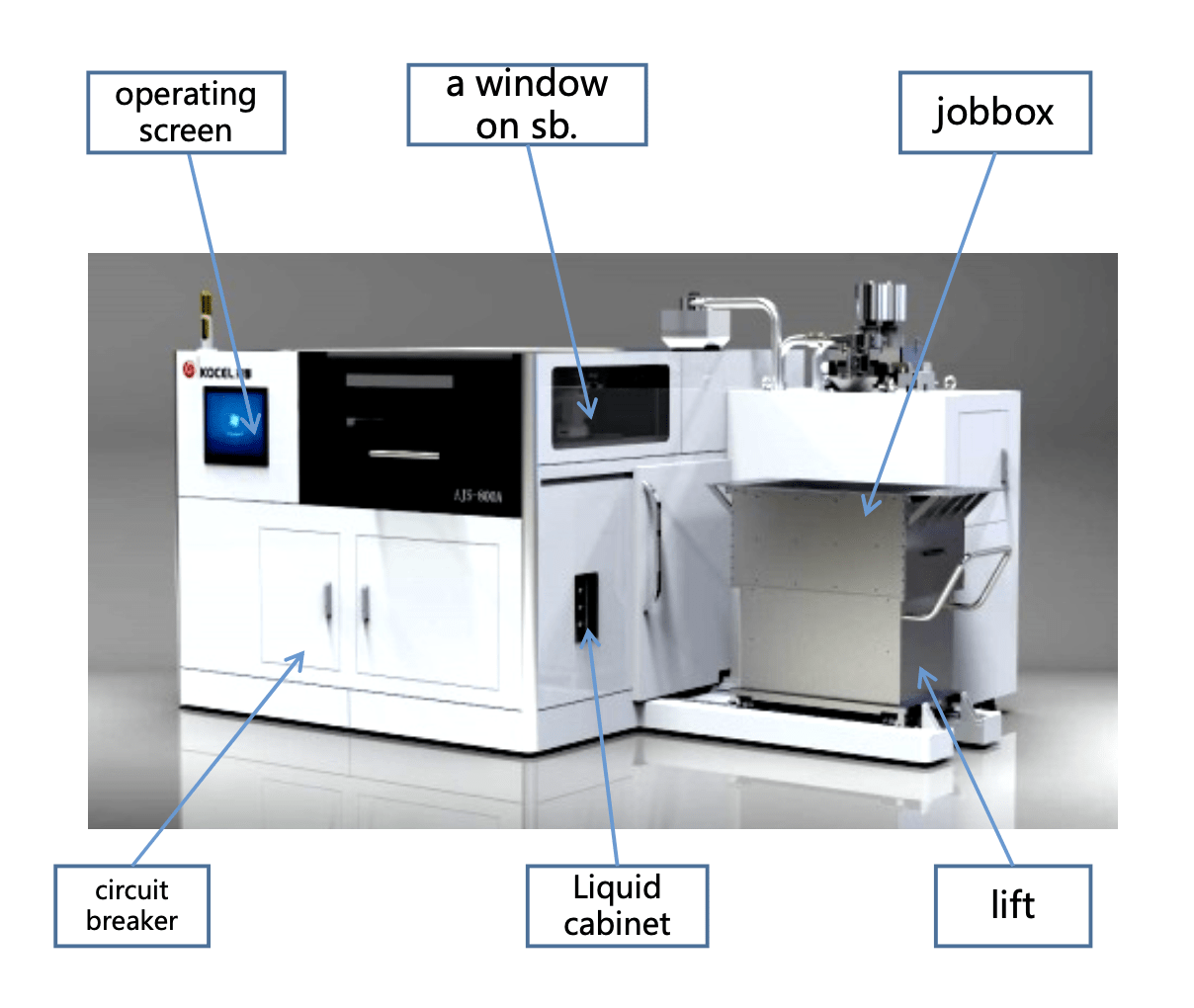

Structure of an AJS 800 sand mold printing machine

SPECIFICATIONS

| model number | AJS 800 | |

| Overall dimensions of the equipment | Length/mm | 2850 |

| Width/mm | 2660 | |

| Height/mm | 2580 | |

| Equipment mainframe size | Length/mm | 800 |

| Width/mm | 500 | |

| Height/mm | 400 | |

| main power | Voltage/V | AC380 |

| Frequency/Hz | 50 | |

| Maximum power/ kW | 8 | |

| compressed air | Working air pressure/Mpa | 0.6 to 0.8 |

| Weight/t | 5t | |

| Printing sand | Silica Sand / Ceramic Sand | |

| bonding agent | resinous | |

| Printing efficiency | 20-35L/h | |

| Printing Accuracy | ±0.3mm | |

| Print File Format | STL | |

| noises | <75 dB | |

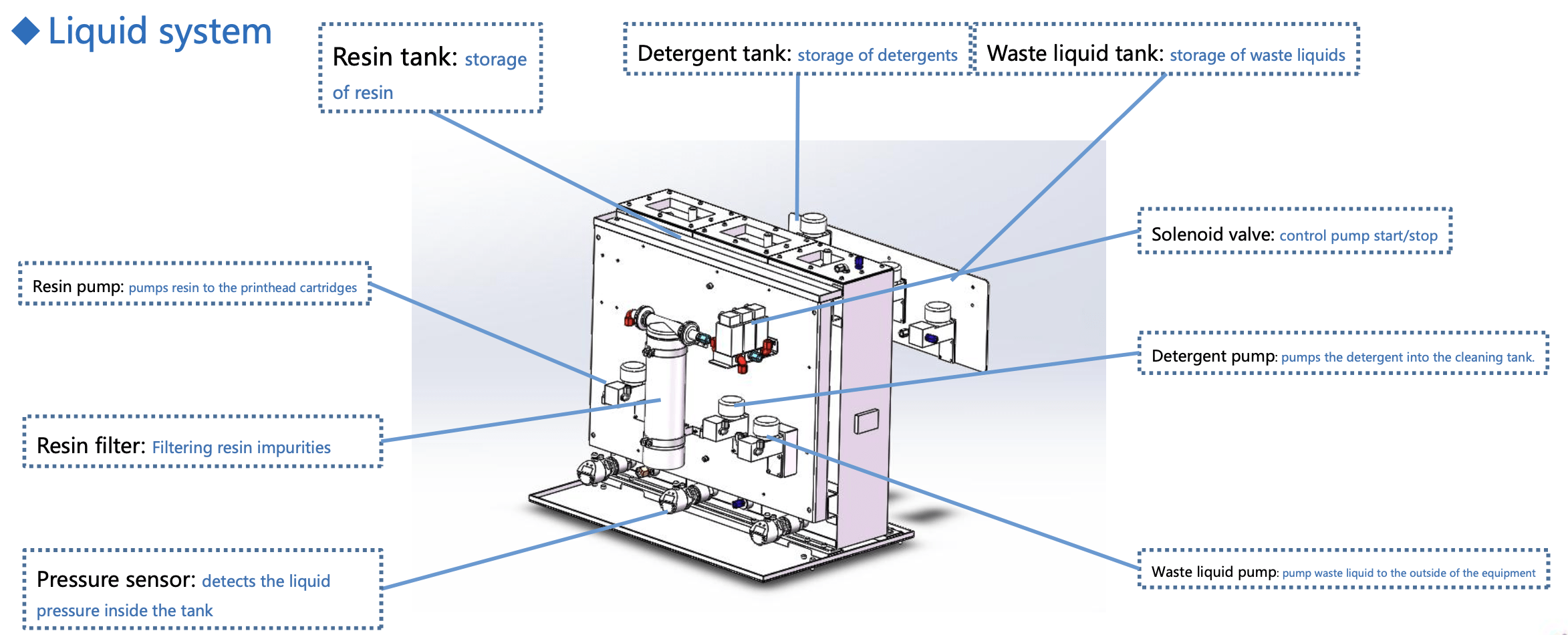

HỆ THỐNG CHẤT LỎNG

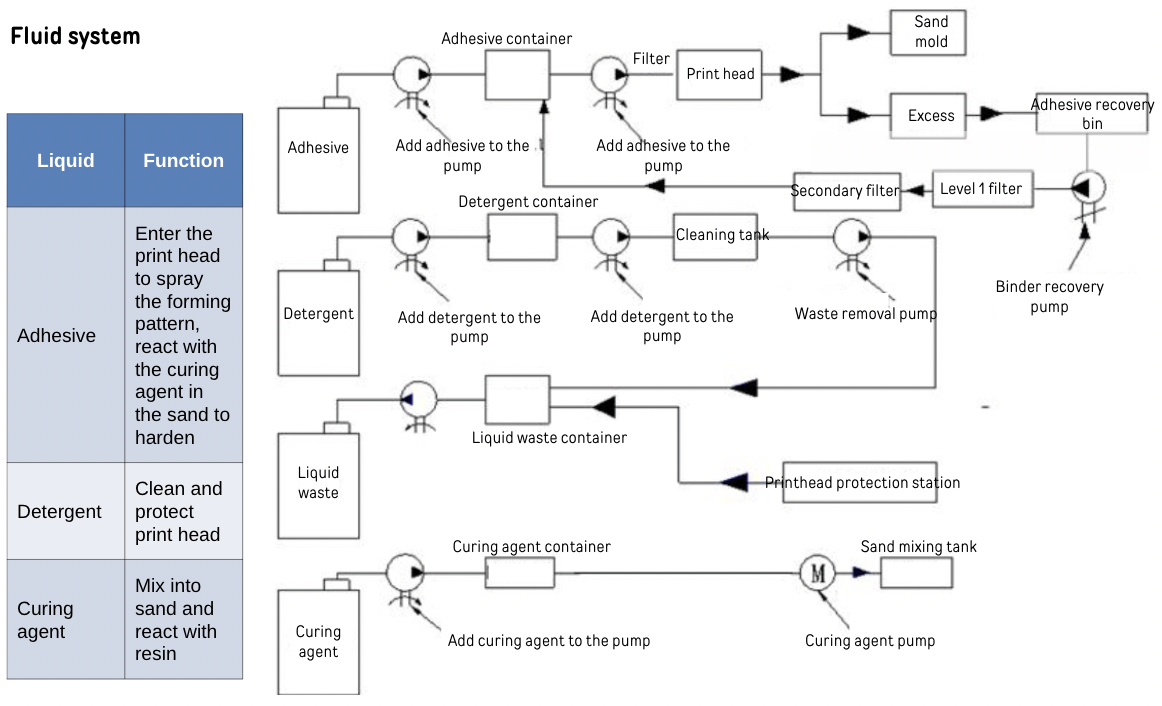

- There are three types of fluids used in this system, crystallizer, detergent and hardener.

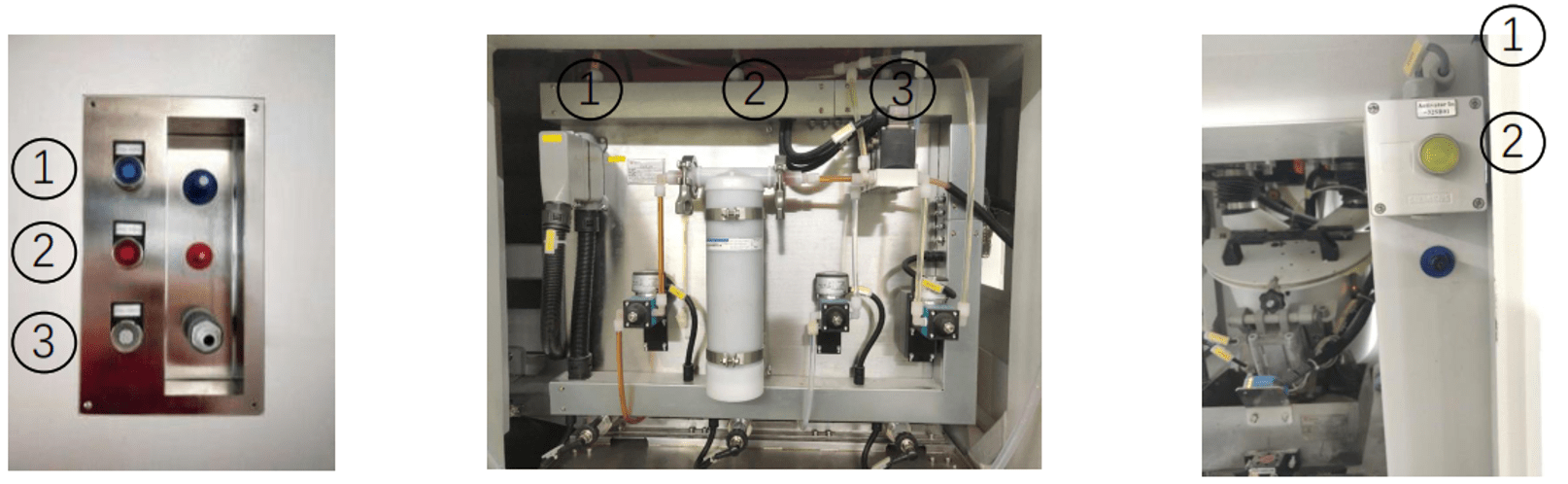

① Adhesive Add Button

② Detergent Add Button

③ Liquid Waste Discharge Button

① Adhesive tank

② Detergent tank

③ Liquid waste tank

① Curing agent addition button

② Curing agent addition port

Add adhesive: select the appropriate liquid pump tube and connect to the red connector, press the red button, the adhesive is pumped into the adhesive tank.

Add detergent: select the appropriate liquid pump tube and connect to the blue interface, press the blue button, the detergent is pumped through the pump into the detergent box

Add curing agent: select the appropriate liquid pump tube and the blue connector, press the yellow button, the curing agent will be pumped into the curing box.

Discharge liquid waste: select the appropriate liquid pump tube and connect to the white interface, press the white button, the liquid waste is pumped through the pump out of the device.

FOR MORE INFORMATION ABOUT THE PRODUCT, PLEASE CONTACT US – KOCEL’S EXCLUSIVE REPRESENTATIVE IN VIETNAM TO RECEIVE DOCUMENTS.

Address: BT6-30 Ngoai Giao Doan, Xuan Tao Ward, Bac Tu Liem District, Hanoi

Hot.line: 0862170366

Email: contact@scantechvn.com/ kdscantech@gmail.com

Fanpage: https://www.facebook.com/scantechvn

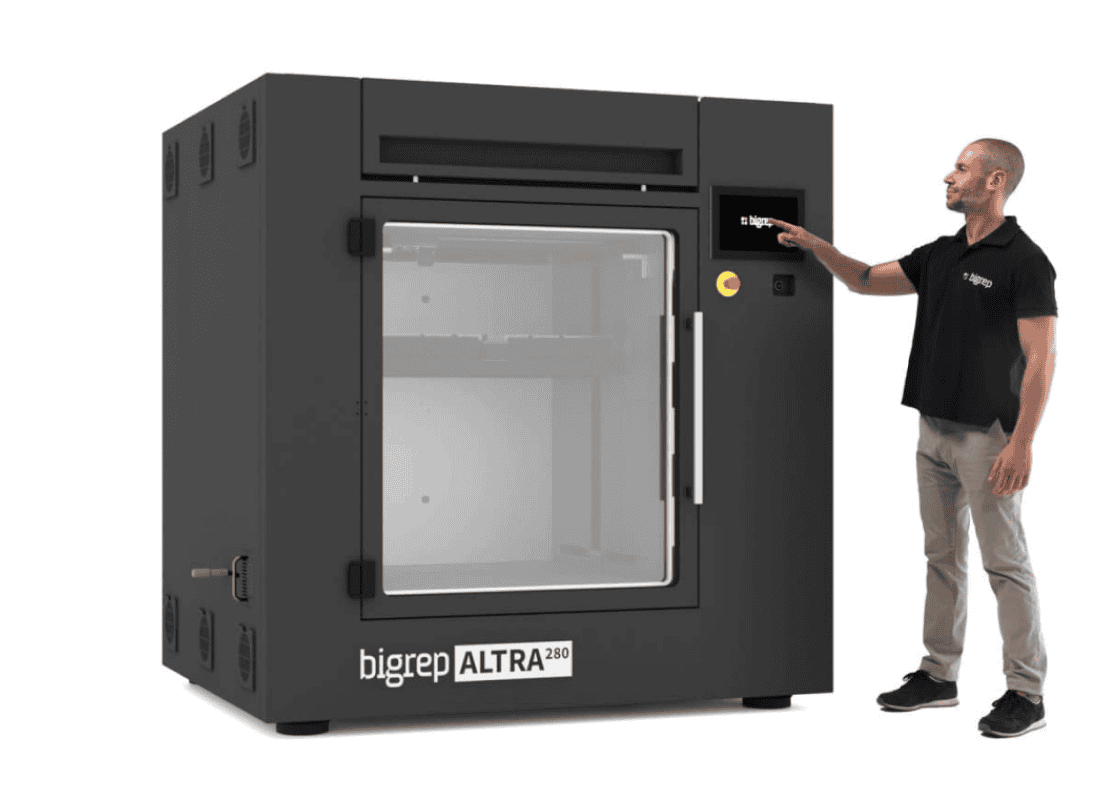

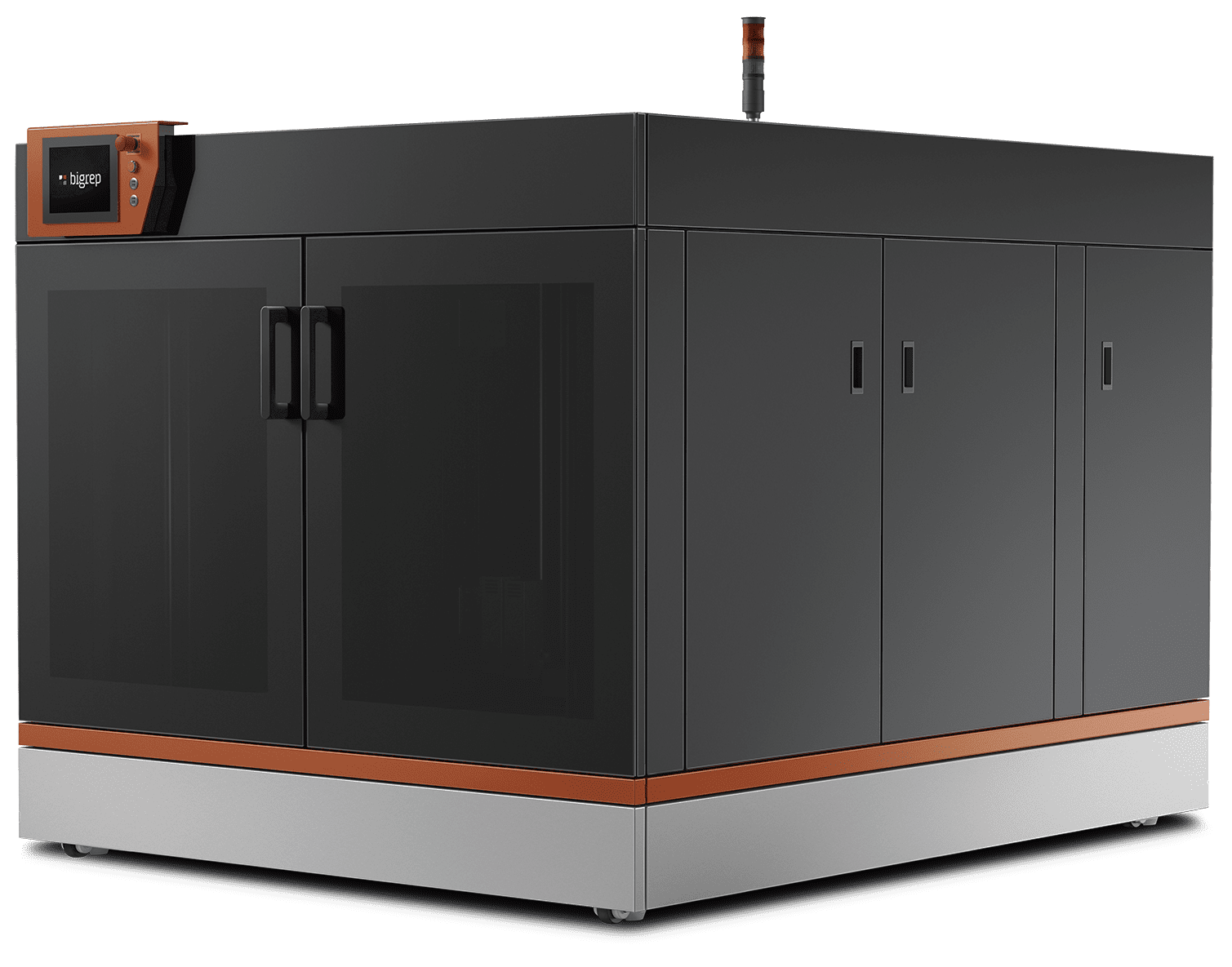

RELATED PRODUCTS

CONTACT

- Login /

- Register