Reverse engineering describes the process of reverse engineering a part or tool. In contrast to the conventional development process for a part, where the design data is usually available from the beginning, here the data is taken directly from the part or tool itself.

What is reverse engineering?

Reverse engineering involves analyzing an object, machine or product to understand its design, form, function and components.

This method is commonly used in product development, manufacturing and maintenance, extracting data from physical objects or systems and converting them into digital format.

It is especially useful for gaining insight into a product or machine. By dissecting and reconstructing a product or part, weaknesses and design flaws can be identified and fixed. This also makes repairing or reengineering a product faster and more cost-effective.

Often used by companies to analyze improvements to their own products or to update older products. It can also speed up the product development process by speeding up the creation and optimization of prototypes.

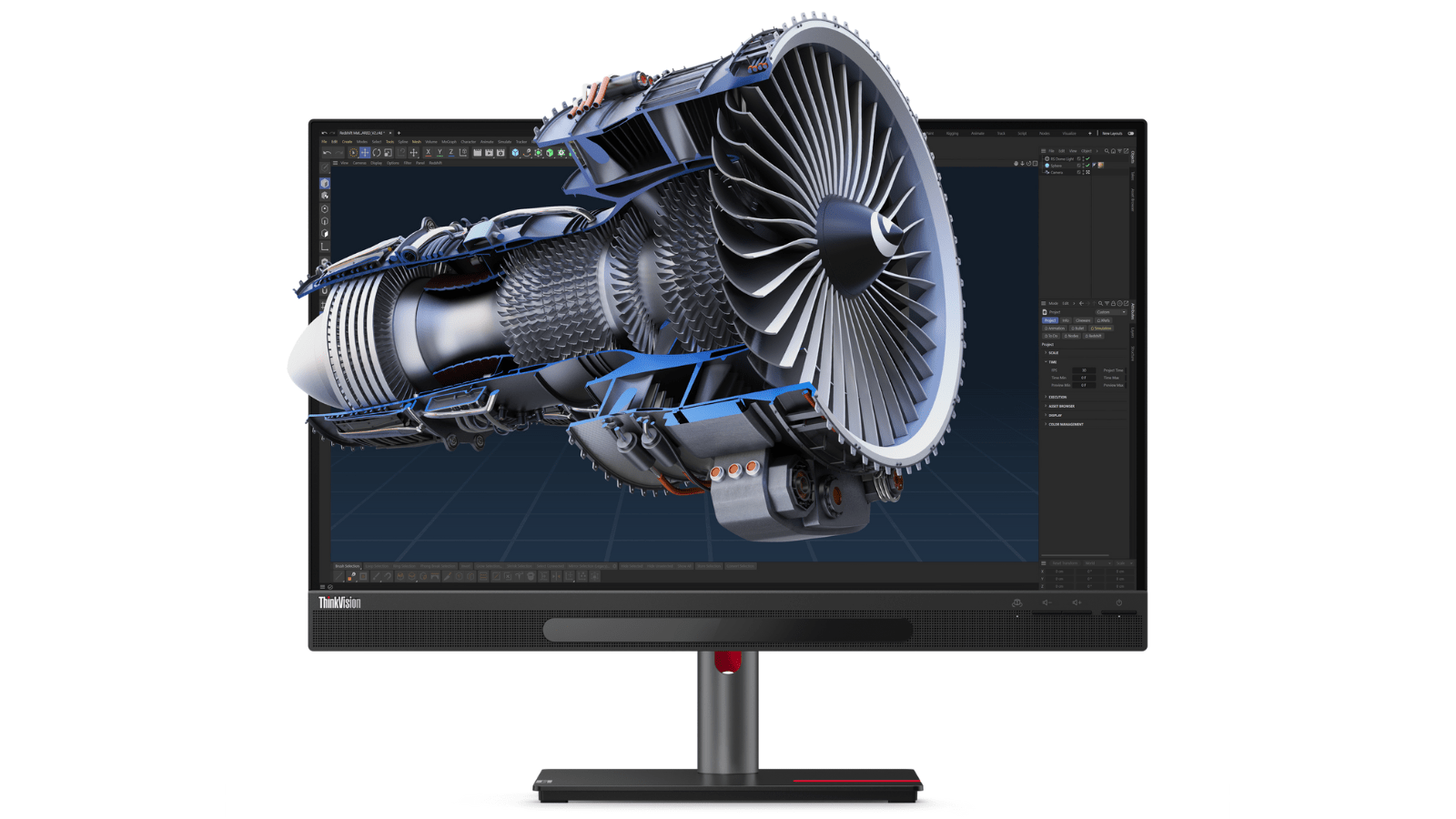

Many different methods are used in reverse engineering, including 3D scanning, which helps capture the structure and geometry of an object. Additionally, CAD models can convert physical objects into a digital format for analysis.

How does reverse engineering work?

The first step in reproducing surface data into design data is to use a 3D scanner. These allow for non-contact scanning of the entire surface of the part. Using millions of measurement points, ZEISS INSPECT software calculates 3D coordinates by creating a high-resolution point cloud, called an STL mesh.

This polygonal mesh forms the basis for creating a CAD model as part of the surface reconstruction process. To convert the scan data into mathematically described curves (splines), freeform surfaces (NURBS surfaces), standard geometry (primitives) or solids, the data can be exported from ZEISS INSPECT software as an STL mesh or an ASCII point cloud.

The actual conversion of the scan data into a CAD surface model requires specific software packages, such as Geomagic, Tebis and ZEISS REVERSE ENGINEERING. Some CAD programs today also have modules for surface reconstruction.

To ensure that the CAD surfaces actually match the scan data, this newly created surface data can be imported back into ZEISS software for validation. ZEISS software can then be used to calculate the deviations between the new CAD data and the scan model for accuracy analysis and visualize them as color deviation representations.

Reverse engineering software

Widely used in industries such as automotive, aerospace, and manufacturing. There are many software tools available for it in these fields. Each method usually has dedicated software or tools included in a comprehensive software package, such as CAD software, 3D scanning software, image processing software, and source code analysis tools.

ZEISS has developed its own reverse engineering software called ZEISS REVERSE ENGINEERING. Built on a core surface reconstruction module, the software offers two additional functions: Tool Calibration and Volume Calculation. This flexibility allows users to choose the option that best suits their needs.

Examples of Reverse Engineering

Used in a variety of fields and industries to analyze, improve, or replicate products, systems, and parts. Here are some real-world examples and applications of reverse engineering in various industries:

- In the automotive industry, reverse engineering is used to analyze and refine the geometry of existing components. For example, 3D scanning of automotive parts can help improve the aerodynamics of a car or produce replacement parts for discontinued models when the original parts are no longer available.

- Reverse engineering is used in the manufacturing industry to create prototypes and streamline the manufacturing process. This involves using 3D scanning and CAD models to optimize the production of components or products and identify defects or weaknesses.

- In the aerospace industry, reverse engineering is used to analyze and refine complex components and systems. 3D scanning and CAD modeling can improve the safety of an aircraft or spacecraft and make maintenance easier by highlighting weak spots and defects.

- Used in software development to analyze program functionality and identify errors and bugs in source code. Source code analysis tools can help improve program security and fix functional bugs.

- Also used in conjunction with new technologies. Digitized 3D surface models serve as the basis for 3D printing or as input data for VR applications, for example.

Advantages and disadvantages of reverse engineering

Reverse engineering offers many benefits, including saving time, reducing costs, and improving product quality.

Here are some of the key benefits:

Save time

By analyzing and optimizing existing products or components, reverse engineering can significantly reduce the time required for product development and manufacturing.

Reduce costs

By closely examining and optimizing existing products or components, reverse engineering helps cut product development and manufacturing costs.

Improved product quality

Reverse engineering can help improve product quality by analyzing and optimizing existing products or components.

However, reverse engineering comes with certain challenges, especially for those less familiar with the subject and the software involved. These challenges include potential reconstruction errors or inaccurate data.

Here are some of the main disadvantages:

Độ phức tạp

Reverse engineering can be very complex, especially when dealing with complex components or systems. It often requires specialized knowledge and skills to accurately analyze and interpret the data.

Inaccurate data

Inaccuracies can arise if methods and procedures are not applied properly or if the data collected lacks precision, for example when using calipers.

Reconstruction error

Inaccurate data or erroneous analysis can lead to reconstruction errors, reducing the reliability of reverse engineering.

ZEISS REVERSE ENGINEERING simplifies this process with a user-friendly interface that guides the user through each step of the software application. This minimizes operating errors and the possibility of inaccuracies right from the start. In addition, ZEISS offers comprehensive training courses to equip users with the skills needed to operate the software effectively in just a few days.

Reverse Engineering in Business

Companies use reverse engineering in a variety of ways to improve their products or create new ones. Here are some of its most common applications in business:

Product Improvement

Reverse engineering can help improve existing products by analyzing and optimizing their components or systems.

Repair & Maintenance

Help repair or maintain damaged components or systems by creating exact replicas.

Product Development

Serve as a foundation for developing new products, using existing products or components as a starting point.

In addition to these benefits, reverse engineering offers another significant advantage:

Protecting Intellectual Property

Companies can protect their intellectual property by analyzing existing products or components and implementing protective measures where necessary.

With ZEISS REVERSE ENGINEERING, you can take advantage of these benefits and take your company to the next level.

Enhance quality assurance with reverse engineering: is an important process that can help improve products and processes and develop new products. Techniques such as 3D scanning enable the creation of exact replicas of components and systems, and specialized software supports these reverse engineering efforts.

There are many advantages to reverse engineering, including improving product quality, reducing costs, and saving time. Companies use this technology in a variety of ways to improve existing products or develop new ones.

In short, reverse engineering is a key method for optimizing and improving products and processes. Businesses should consider it a valuable tool and use its various methods and processes to their full potential.

SCANTECH VIETNAM COMPANY

Address: BT6-30 Diplomatic Corps, Xuan Tao Ward, Bac Tu Liem District, Hanoi

Hot.line: 0862170366

Email: contact@scantechvn.com / kdscantech@gmail.com

Fanpage: https://www.facebook.com/scantechvn

OTHER NEWS