What is a QuickCast template?

QuickCast™ is a registered trademark of 3D Systems

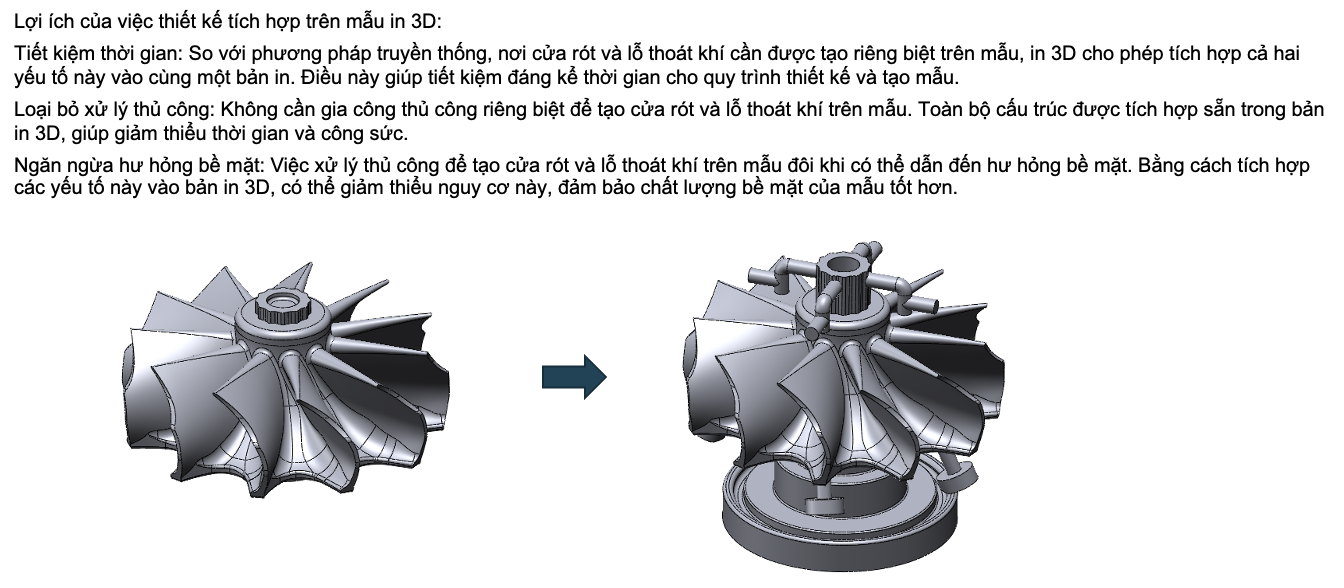

QuickCast is a type of SLA 3D printed model specially designed for use in the wax casting method.

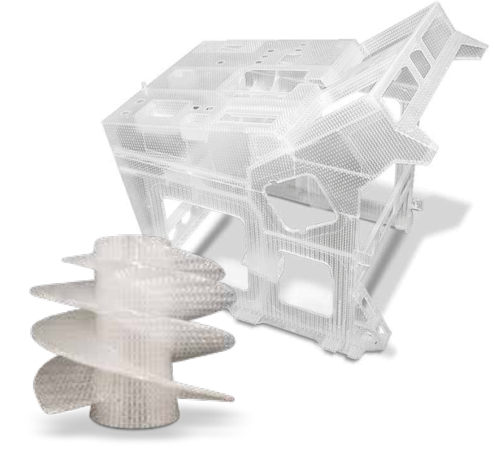

The unique feature of QuickCast models lies in their internal structure:

Fast printing time: Compared to solid 3D models, QuickCast models have significantly faster printing times.

Hollow with an internal honeycomb structure: Unlike conventional 3D printed models, QuickCast models are designed to be about 80% hollow inside with a honeycomb structure.

Preventing shell cracking: This hollow honeycomb structure helps the model easily shrink inside during the casting process, especially during the autoclave and burnout stages. Thanks to that, QuickCast models help minimize the expansion pressure inside the casting shell, preventing shell cracking.

Saving materials: The hollow design also helps to significantly reduce the amount of printing material needed, saving model production costs.

High geometric stability: QuickCast models have high geometric stability, ensuring safety during transportation and storage.

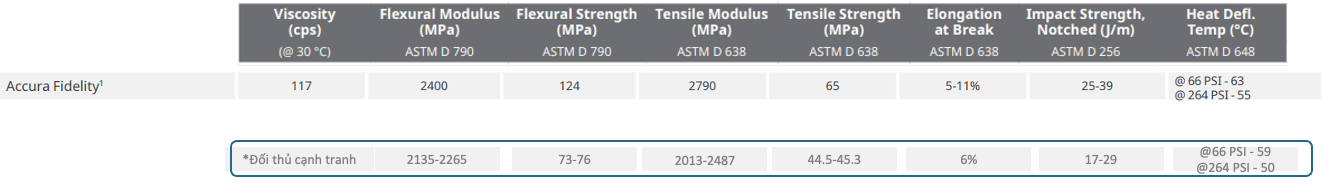

Materials used for QuickCast

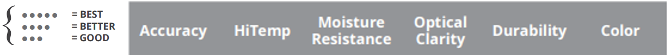

ACCURA® FIDELITY™ advanced material

•Helps the process of removing the sample material (burnout) to be almost ashless (< 0.01%), antimony-free (Antimtony is a toxic substance often found in some 3D printing materials)

•Low viscosity (helps the material to flow easily out of the casting shell during removal)

•Low moisture absorption, smooth surface, high dimensional stability, very suitable for the production of large samples

•Versatile applications: can be used to create castings for many different metals, including titanium, aluminum, magnesium, zinc and even cast iron.

ACCURA® FIDELITY™ advanced material

•Helps the process of removing sample material (burnout) to be almost ashless (< 0.01%), antimony-free (Antimtony is a toxic substance often found in some 3D printing materials)

•Low viscosity (helps the material to flow easily out of the casting shell during removal)

•Low moisture absorption, smooth surface, high dimensional stability, very suitable for the production of large samples

•Versatile applications: can be used to create castings for many different metals, including titanium, aluminum, magnesium, zinc and even cast iron.

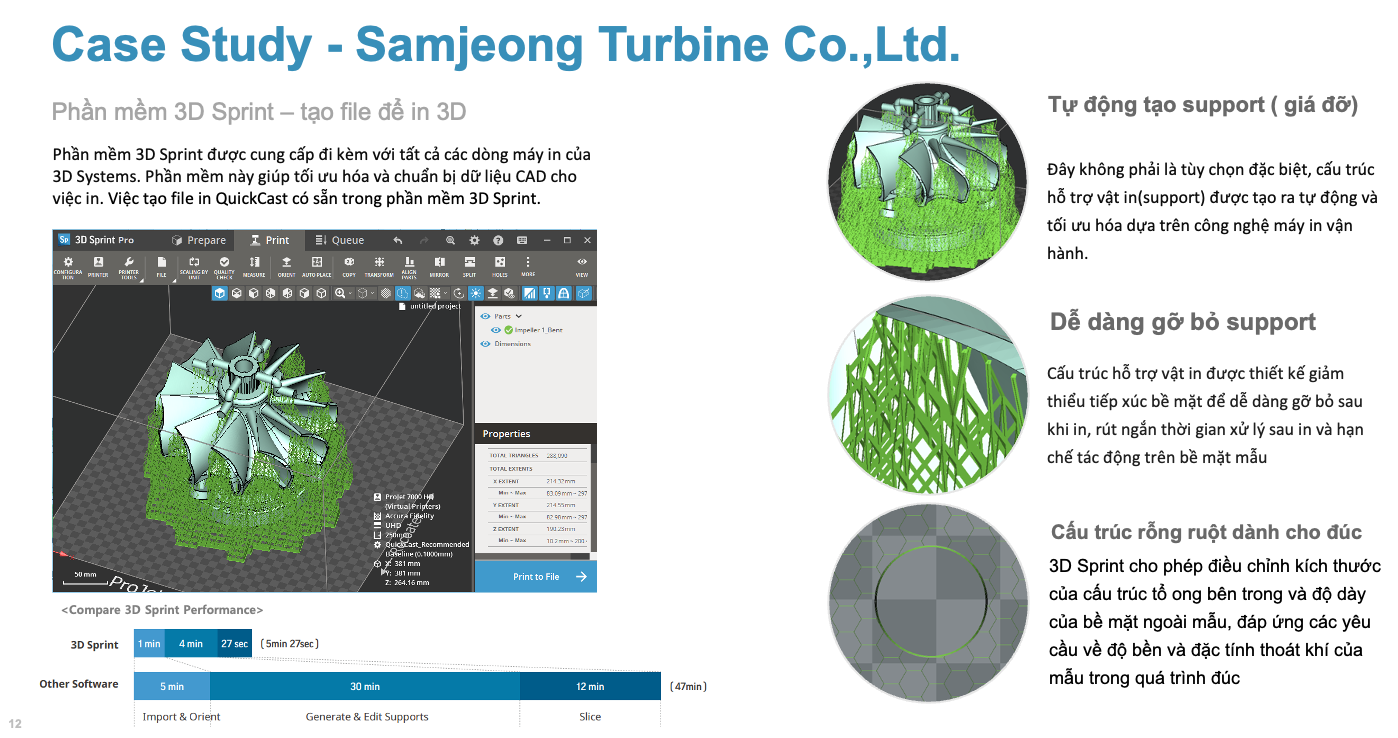

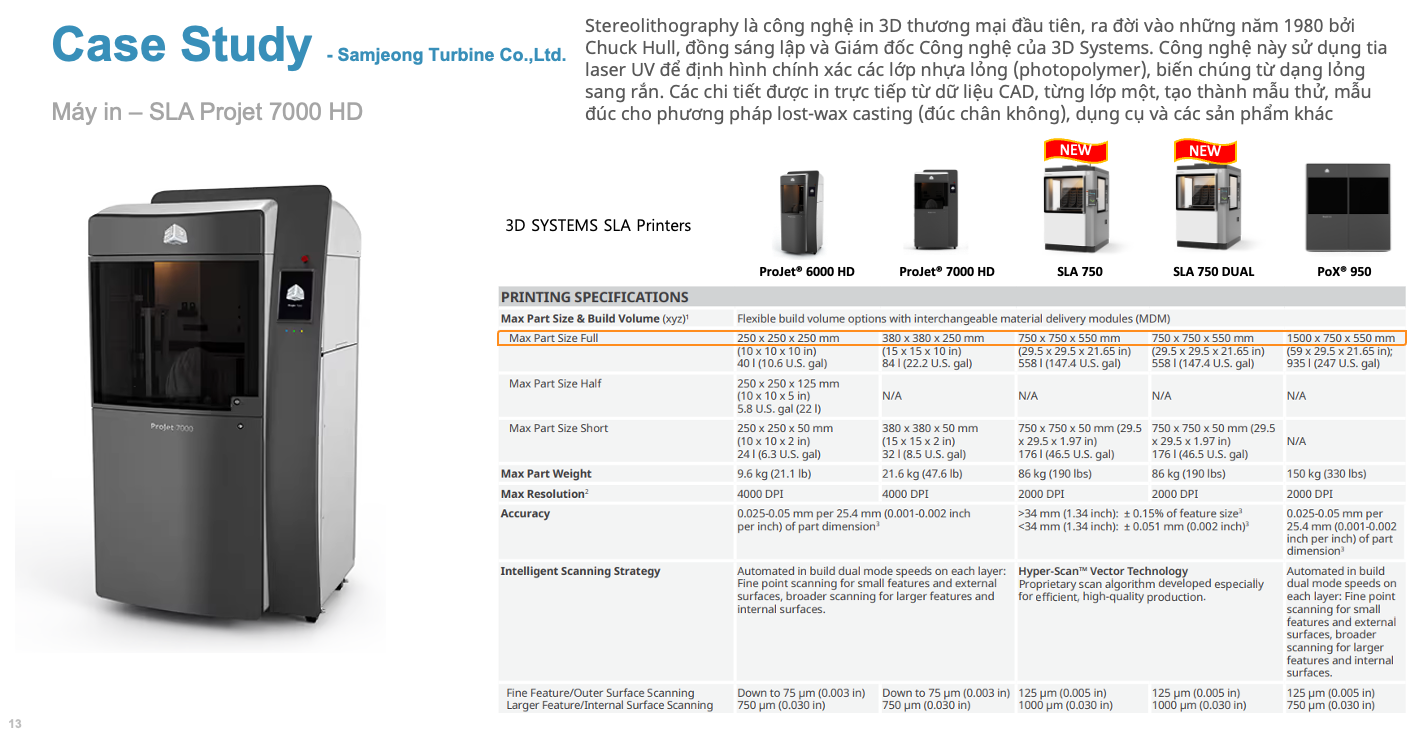

Some typical Case Studies about QuickCast printing samples

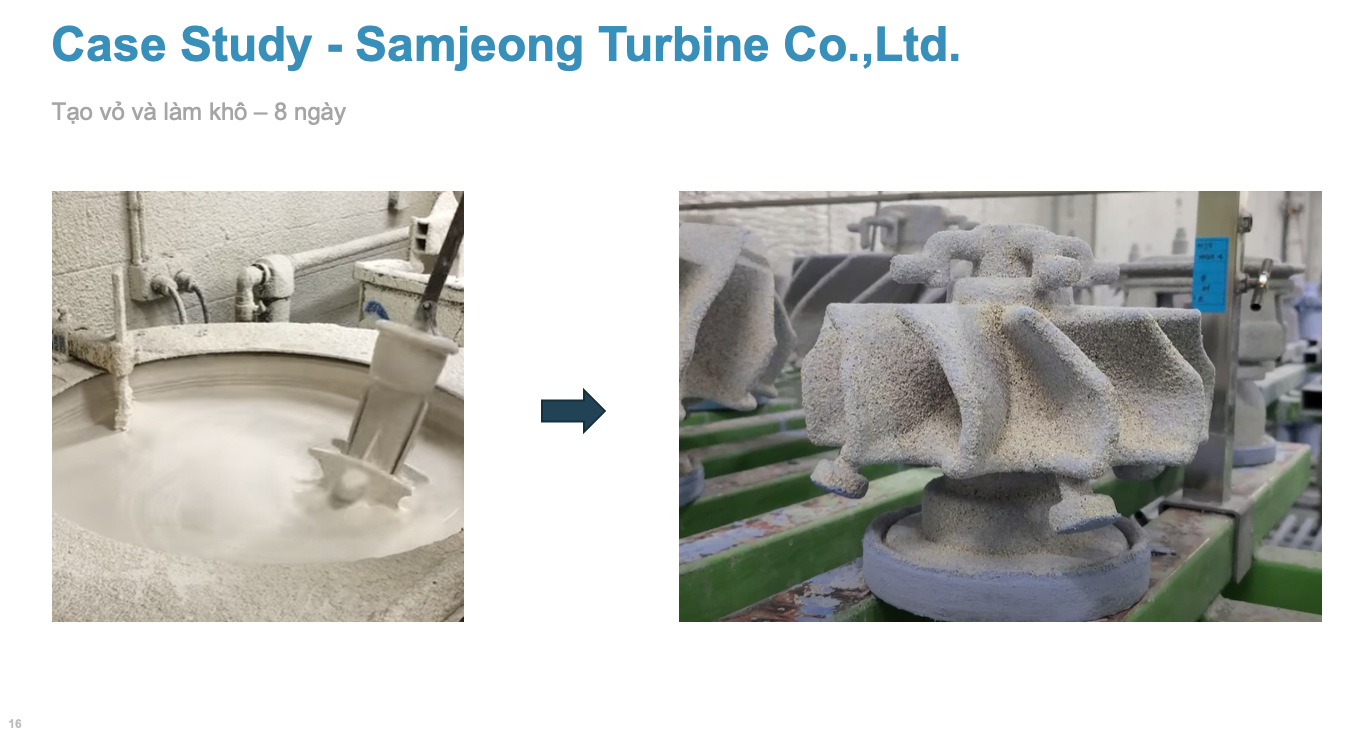

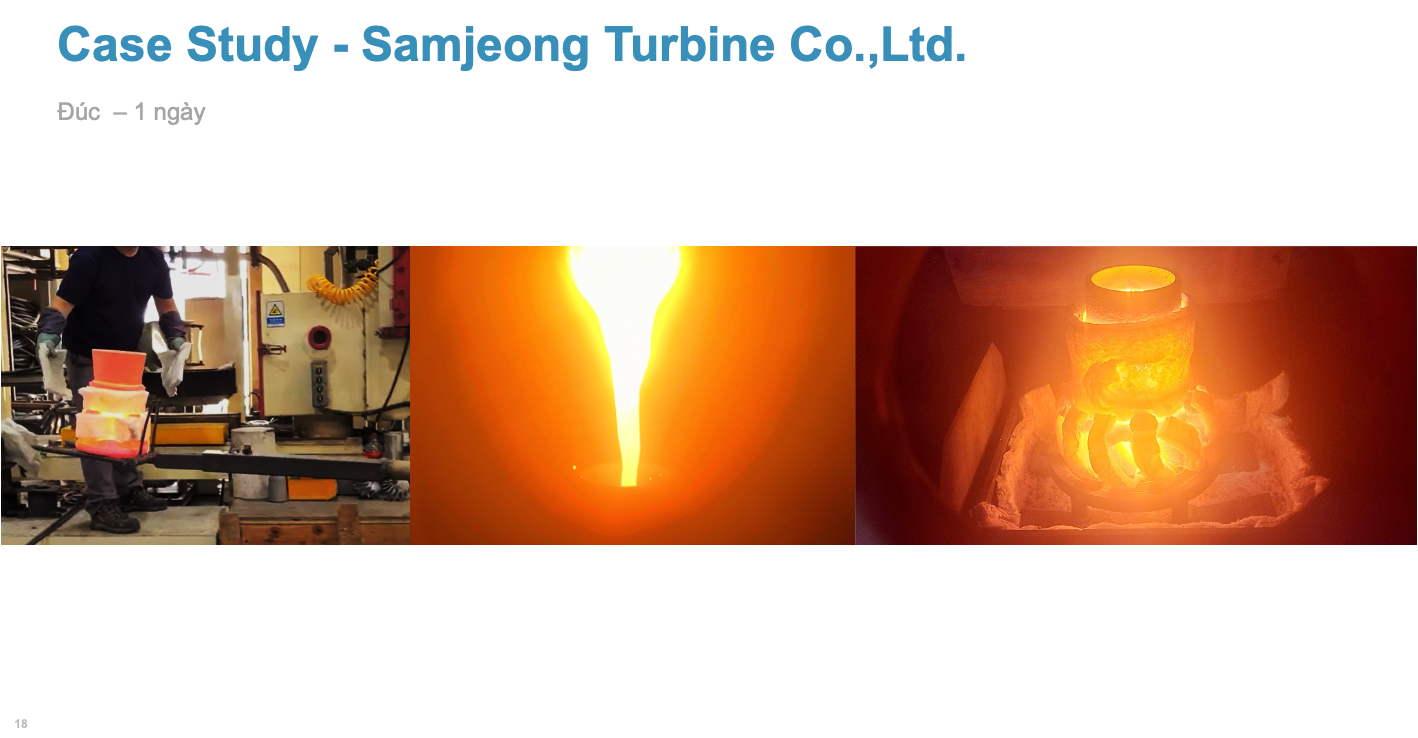

- Samjeong Turbine Co.,Ltd.

XIN CHÂN THÀNH CẢM ƠN QUÝ KHÁCH HÀNG VÀ ĐỐI TÁC LUÔN TIN TƯỞNG VÀ ĐỒNG HÀNH CÙNG CHÚNG TÔI.

CÔNG TY SCANTECH VIỆT NAM

Địa chỉ: BT6-30 Ngoại Giao Đoàn, P. Xuân Tảo, Q. Bắc Từ Liêm, HN

Hot.line: 0862170366

Email: contact@scantechvn.com / kdscantech@gmail.com

Web: scantechvn.com

OTHER NEWS