Scantech VN | Industrial-Grade Mold 3D Printing Solutions

In today’s manufacturing world, molds are the core of the production process — shaping materials like plastic, metal, and composites.

Traditional mold fabrication is costly and time-consuming, placing constant pressure on deadlines and budgets.

With Scantech VN’s Mold 3D Printing Services, this process becomes faster, more flexible, and more cost-effective.

We empower businesses to create molds, prototypes, and finished parts with high precision, reduced lead time, and lower production costs.

Two Key Applications of Mold 3D Printing

3D Printing End-Use Products

Beyond mold fabrication, 3D printed molds can directly produce finished or functional prototypes.

This is ideal for R&D, product testing, or limited production runs.

Applications:

-

Validate design geometry and assembly.

-

Produce short-run functional parts for testing.

-

Optimize designs before full-scale machining.

3D Printing Molds, Cores & Inserts

At an industrial level, mold 3D printing enables the rapid creation of mold cavities, cores, and inserts with complex cooling or geometry.

Advantages:

-

Reduce mold-making time by up to 70%.

-

Enable freeform design for complex channels and surfaces.

-

Easily reprint damaged components without retooling the entire mold.

Industries:

-

Metal casting: rapid core and cavity creation.

-

Plastics & composites: prototype molds and injection tooling.

-

Mechanical production: jigs, fixtures, and production tools.

Technologies & Materials Used

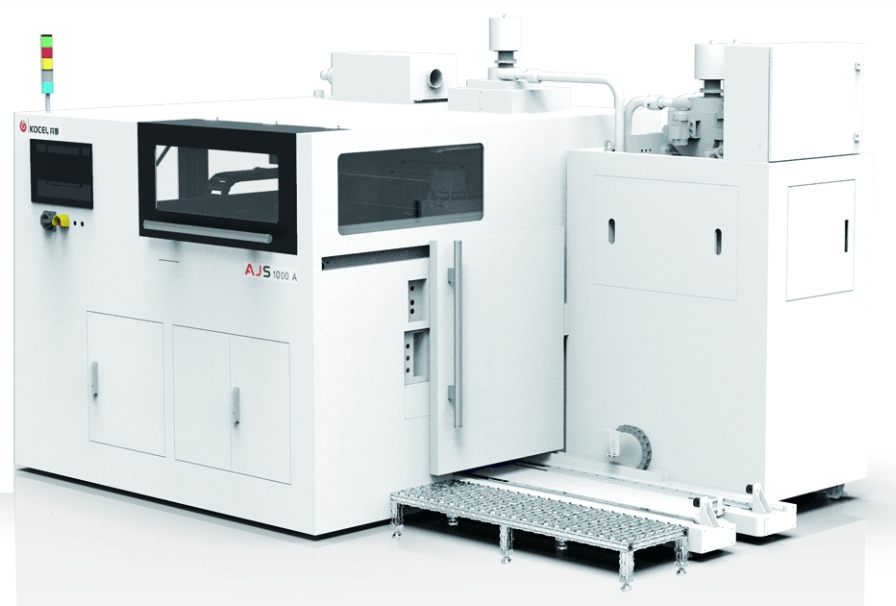

Scantech VN applies SLA, FDM, and MJP technologies to support diverse material needs:

-

Engineering-grade plastics – ideal for short-run or test molds.

-

High-resolution resin – suitable for small or detailed aesthetic molds.

-

Hybrid composites – reinforced for durability and heat resistance.

Why Choose Scantech VN Mold 3D Printing Services

✅ Faster turnaround: cut mold fabrication time from weeks to days.

✅ Lower cost: save up to 50% on test molds and prototyping.

✅ Design freedom: flexible for R&D and innovation.

✅ Optimized workflow: reduced waste, faster time-to-market.

Scantech VN – Your Trusted Partner for Digital Mold Manufacturing

At Scantech VN, mold 3D printing is part of a complete digital manufacturing ecosystem.

From consultation, material selection, and design validation to final production, we ensure every mold meets industrial precision standards.

👉 Scantech VN transforms 3D mold printing into a real manufacturing advantage — helping Vietnamese businesses innovate and compete globally.

📞 Contact Us

Hotline: 0904 985 139 / 0862 170 366

Email: ktscantech@gmail.com

Website: scantechvn.com

Facebook: facebook.com/scantechvn

Showroom: BT6-30 Ngoại Giao Đoàn, Xuân Đỉnh Ward, Hanoi

OTHER NEWS