When people think of 3D printers, they often think of a complicated printing process, but that’s not the case. There’s a lot of fun involved in creating an object from a 3D printer. Here’s how a consumer-grade 3D printer works. Note that you have to use a 3D image to print.

Input is plastic fiber, output is adhesive resin

3D printer users will have two input materials to choose from: Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA). Some printers only accept ABS, while others accept both. These input plastic materials come in filament form, 1.75mm or 3mm wide.

ABS plastic is often used to create Lego toys. It is a chemical-based plastic that is activated at high temperatures. PLA plastic is derived from natural sources, such as corn and sugarcane, and is harder and shinier than ABS plastic. In addition to being used as an input material for 3D printers, PLA plastic is also used to produce biodegradable packaging.

3D printer filament is quite expensive. MakerBot sells 2.2 pounds (990 grams) of PLA filament for $48. If you buy it on eBay, it will be half the price. The company estimates that 990 grams of filament can print 392 chess pieces.

The price of filament will decrease if 3D printers become popular and filament is produced on a large scale. Another way to reduce the input cost is to use a filament extruder. You feed recycled or cheap plastic into the extruder to create filament.

Once you have the filament, you feed it into the 3D printer through a part called the print head. The print head is shaped like a box with a nozzle. An actuator pushes each piece of plastic down into the print head. Before the plastic is extruded from the print head, the filament must pass through a heat pipe and become liquefied. The plastic passing through the print head is a super-fine thread of only 0.1 millimeters. Once exposed to air, the plastic dries very quickly, bonding together to form layers.

ABS needs to be printed on a heated surface, which means the bottom layer will curl up slightly. PLA, on the other hand, can be printed on a non-heated surface.

Most 3D printers have a single printhead, meaning the printed object is a single color. To print more than one color, you have to change the filament during the printing process. Some printers, such as MakerBot’s latest Replicator 2x, have two printheads. This allows you to print in two colors. New York-based botObjects is also promising to release a printer that can mix filaments to print objects in a full range of colors.

Print from front to back, layer on layer

3D printing is a layered printing technology. The printing surface (often called the print bed) and the print head work together to perform 3D printing. In the Replicator 2 printer model, the print head is held by a suspension system (illustrated below). 2 horizontal metal bars help the print head move back and forth horizontally. At the ends of these 2 metal bars, 2 other vertical bars are attached, helping the print head move back and forth vertically. Thanks to the suspension system, the print head can also move up and down to create 3D objects.

A printer model called RepRaps has a relatively different way of 3D printing compared to the Replicator 2. The RepRaps print bed moves up and down, back and forth, while the print head only moves horizontally. The DeltaMaker printer model has a print head that moves in all 3 dimensions.

The 3D printing process can take minutes, hours, or even days depending on the size and volume of the product.

For example, some artists recently used Type A Machines printers to print a 3 x 3 x 2.4m dragon head sculpture. It took them up to 2 months to complete the work.Máy in 3D không chỉ in nhựa

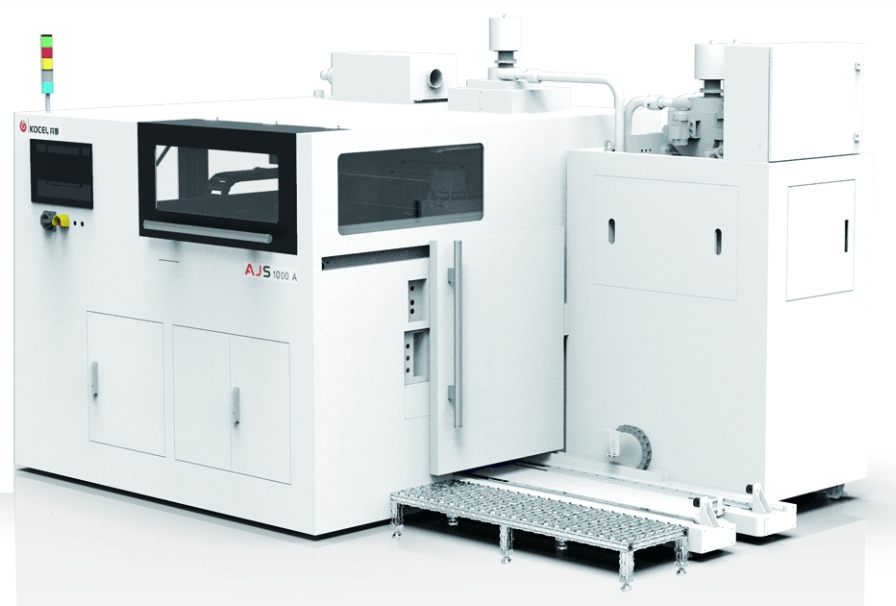

Not all 3D printers use the same materials. Professional 3D printers are capable of creating high-quality products from a variety of materials. At Shapeways, large 3D printers create multiple products at once. Materials aren’t limited to ABS and PLA. They can be made from brass, ceramic, steel, and five other plastics.

Some 3D printers use laser sintering technology, which uses lasers to fuse pieces of material together. Several laser sintering patents are set to expire next year, paving the way for mass production of consumer 3D printers.

OTHER NEWS