1. Introduction to Large Format SLA Plastic 3D Printing

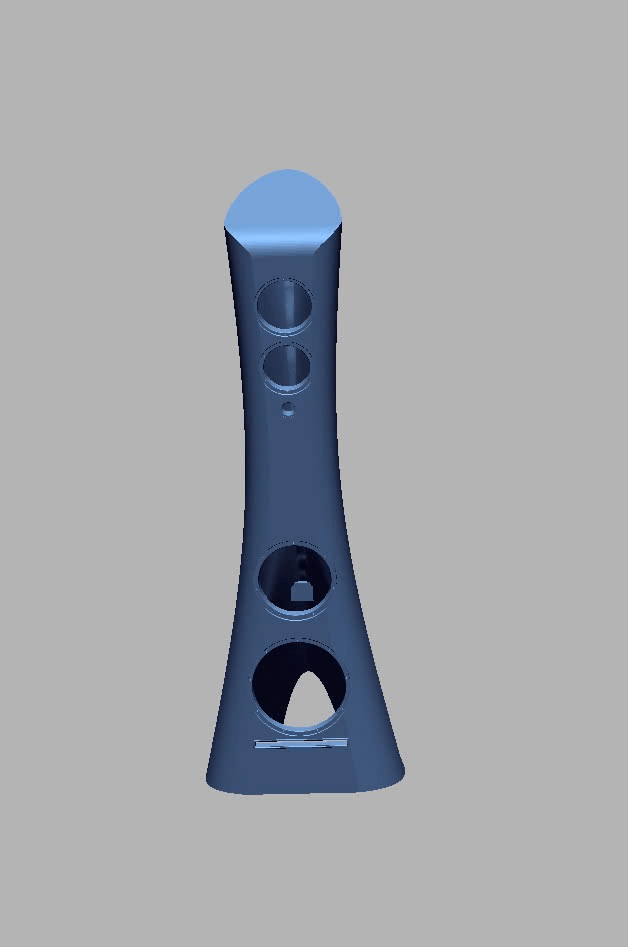

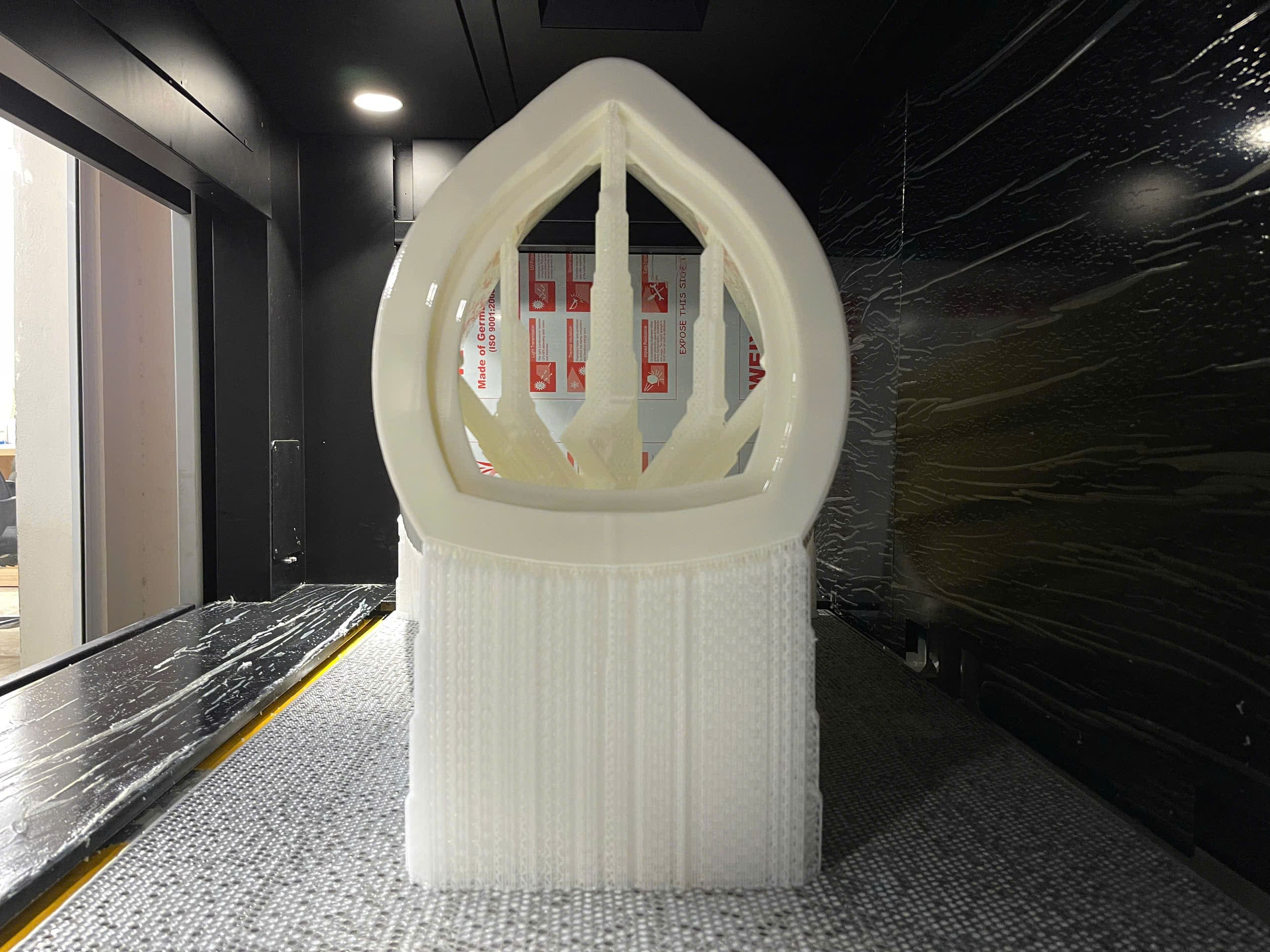

SLA (Stereolithography) 3D printing is a technology that uses lasers to solidify liquid resin layer by layer, creating products with high precision, smooth surfaces and fewer layer lines than FDM printing. When it comes to large-scale SLA 3D printing, this requires equipment with a maximum printing capacity of up to several hundred millimeters to one meter, while maintaining accuracy and consistency throughout the entire process.

2. Reasons to Use SLA 3D Printing for Speakers

Loudspeakers are devices that require high precision in design and manufacturing, especially in terms of shape and internal structure. SLA 3D printing brings many benefits in loudspeaker manufacturing:

High precision: Allows for the creation of sophisticated structures, ensuring optimal sound performance.

Smooth surface: Minimizes material ripple, helping to improve sound quality.

Flexible design: No longer limited by traditional molds, allowing for complex designs.

Fast production: Speaker prototypes can be created quickly, helping to shorten research and development time.

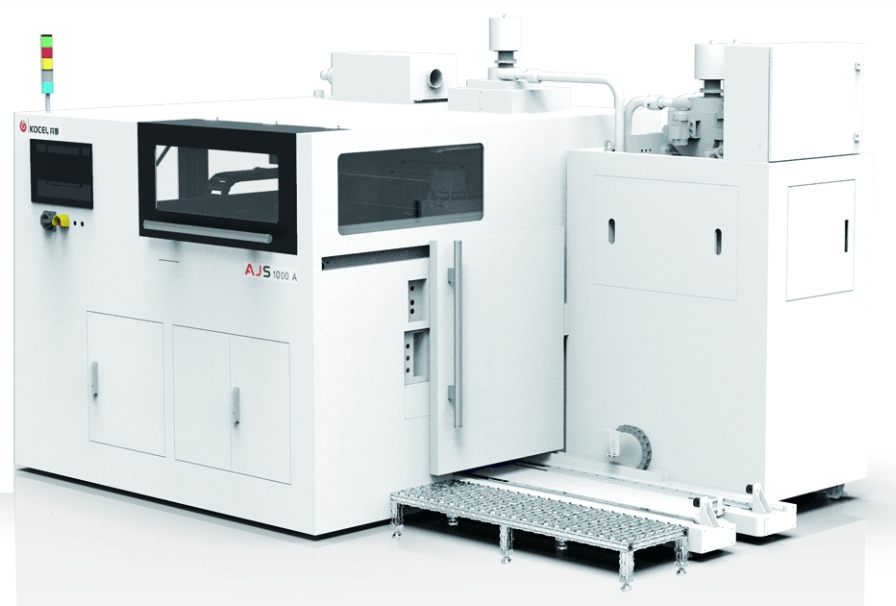

3. 3D speaker printing process at Scantech

Step 1: Create 3D file and design, order file printing.

Step 2: Order printing and receive printed results.

Step 3: Support processing.

Step 4: Proceed to assemble the pieces after drying.

Step 5: Wait for the finished product.

3D Printing a Giant Speaker in One Video

Thus, this is a highly demanding process in every step, Scantech is confident that it can ensure the most stringent factors from customers, thereby producing a perfect product.

THANK YOU CUSTOMERS AND PARTNERS FOR ALWAYS TRUSTING AND ACCOMPANYING US

SCANTECH VIETNAM COMPANY

Address: BT6-30 Diplomatic Corps, Xuan Tao Ward, Bac Tu Liem District, Hanoi

Hot.line: 0862170366

Email: contact@scantechvn.com / kdscantech@gmail.com

Fanpage: https://www.facebook.com/scantechvn

OTHER NEWS