Although 3D printing technology has advanced by leaps and bounds in recent years, most machines still print solid objects using only one material.

A team of researchers from the Massachusetts Institute of Technology (MIT) Department of Computer Science and the Computer Science and Artificial Intelligence Laboratory (CSAIL) has developed new software that can print objects from plastic or other materials.

3D printing hardware that supports printing from multiple materials already exists, but it is difficult to write code that can analyze a 3D model and create instructions that allow you to print parts with different physical properties. Until now, 3D printing an object using multiple materials meant using a high-resolution printer that specified different materials for each specific part of the object. With this method, even if only a small object is printed, with differences (in texture, size, color, surface properties) and a large amount of data to process, the printing process will be extremely expensive.

To simplify the whole process, the CSAIL research team built a software pipeline called “OpenFab”, similar to the modeling pipelines used in the 3D film industry. OpenFab reduces the cost of printing by transferring only a small portion of the data required by the printer. Since only a small portion of the data is stored in the system’s memory at any given time, the entire computation process becomes easier and there is very little chance of a slow start-up.

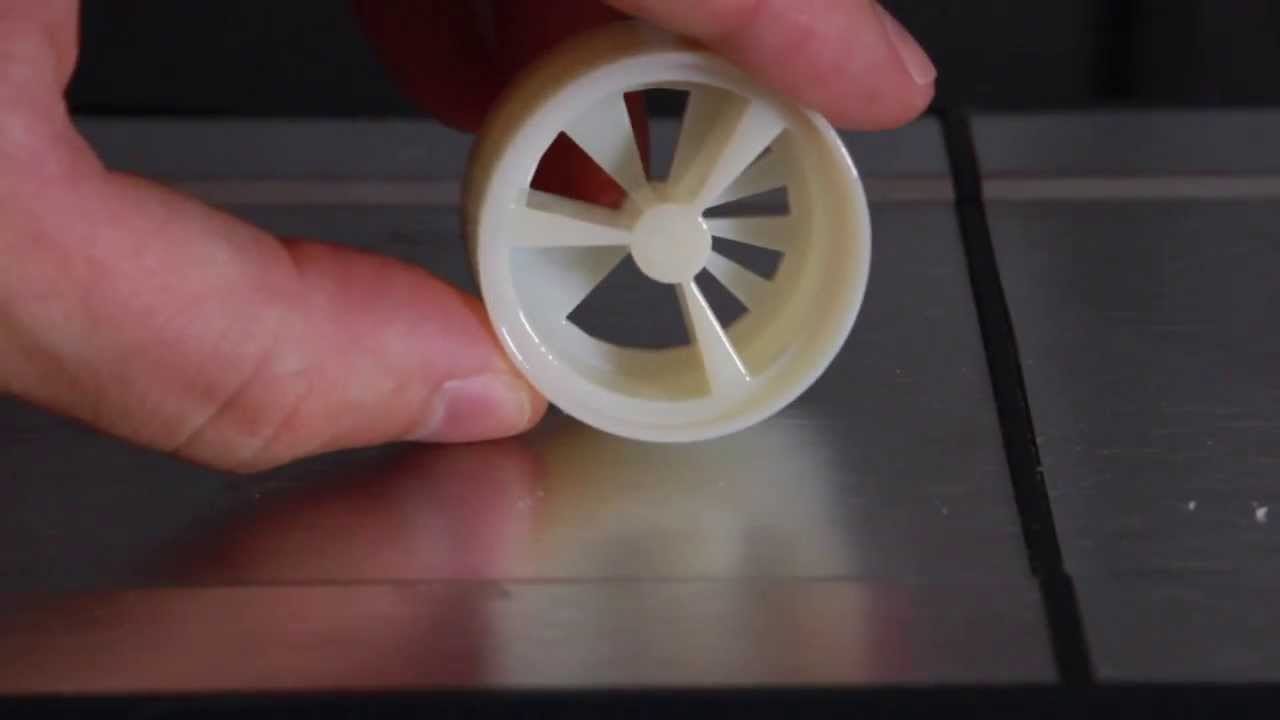

This breakthrough technology not only allows for a variety of printing materials, but also changes the way users view a single material used for printing. It is possible to print an object with stiff and compressible parts, even if it is a non-flexible raw material. The team used OpenFab to print a rhino with small spikes on zebra-like textured skin, a butterfly encased in opaque amber, a bunny, and a soft teddy bear.

OTHER NEWS