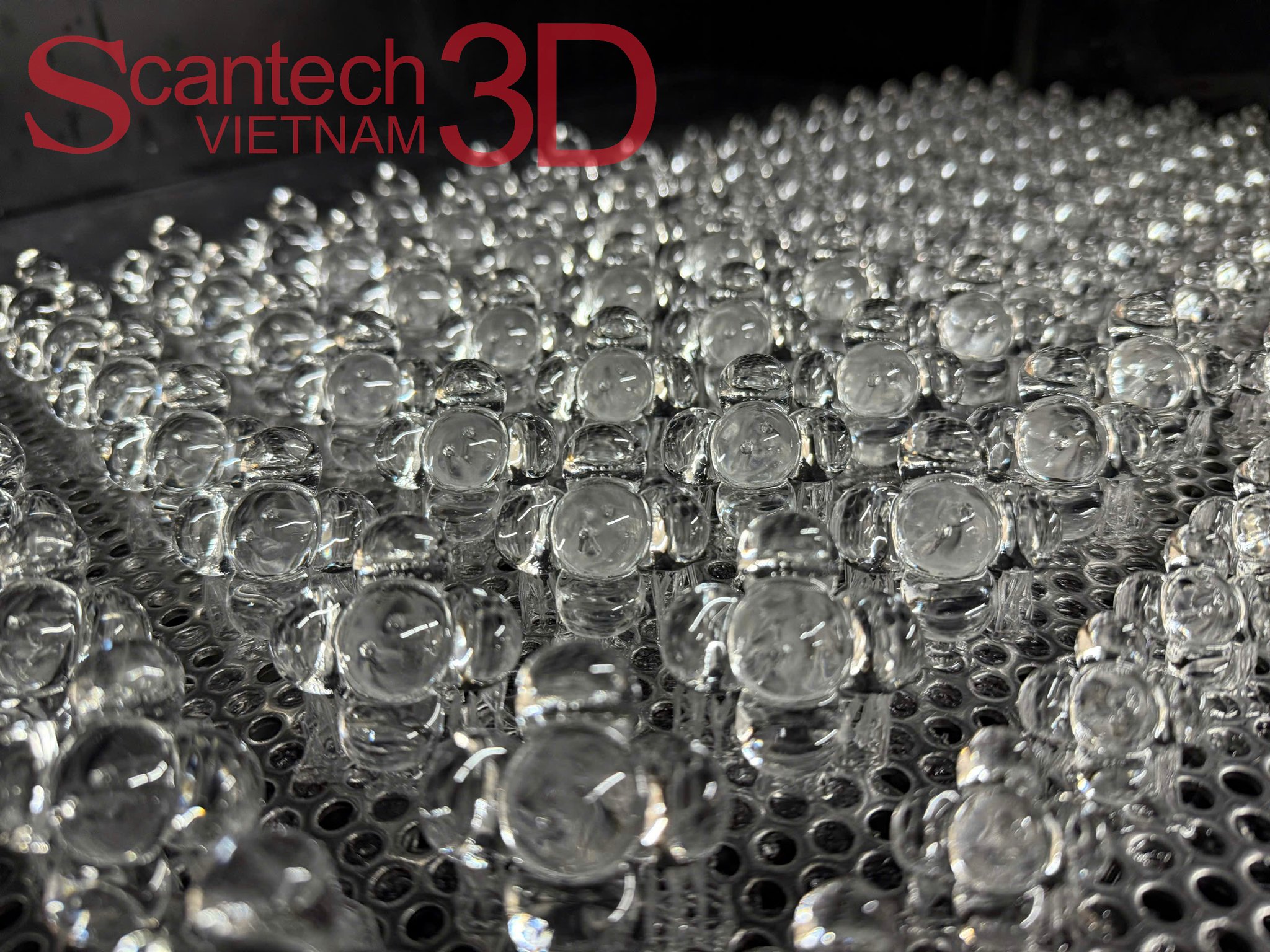

(3D printing transparent plastic) In the era of Industry 4.0, the need for rapid prototyping and product testing has become more urgent than ever. Among the advanced technologies supporting this shift, clear resin 3D printing stands out as a game-changer. It not only shortens product development time but also produces highly detailed models — showcasing joints, curves, and even internal structures with exceptional clarity.

At SCANTECH, clear resin 3D printing is more than just a prototyping service — it’s an end-to-end solution. From file preparation and technical setup to production and post-processing, we handle it all.

Why Is Clear Resin a Preferred 3D printing transparent plastic?

Compared to standard resins, clear resin offers superior advantages:

-

Visible internal structures – Ideal for flow visualization, hollow components, or test-fitting.

-

High aesthetic appeal – Perfect for display purposes and visually striking prototypes.

-

Flexible post-processing – Can be polished, UV-coated, or dyed for enhanced transparency and surface protection.

-

Versatile applications – From mechanical parts to medical, fashion, packaging, and cosmetic designs.

What Makes SCANTECH’s Clear Resin Printing Stand Out?

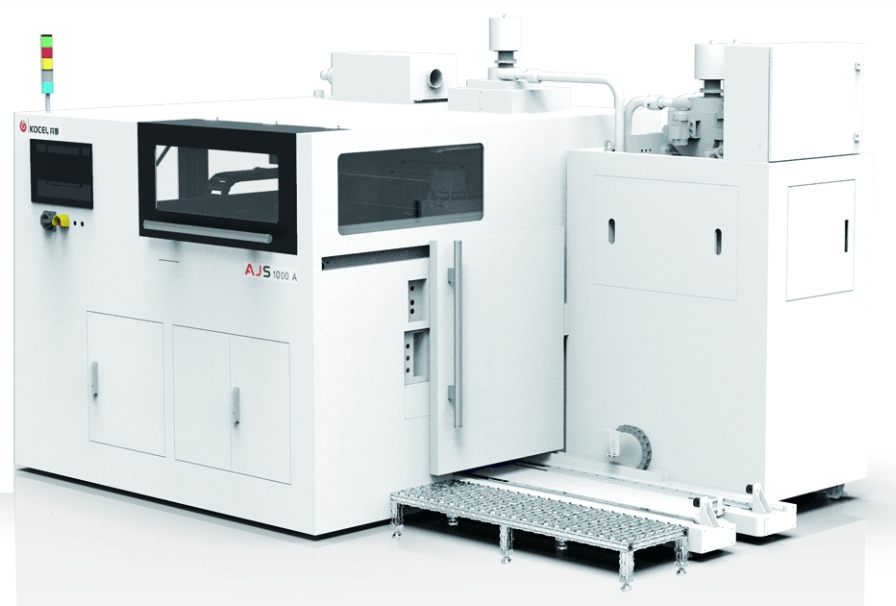

We use industrial SLA/DLP 3D printing technology with ultra-high resolution. Materials are carefully selected from premium clear resins that meet strict EU export standards.

Our standard process includes:

-

Technical consulting – Evaluate your files or create new designs from physical samples.

-

Print file preparation – Optimize orientation, add supports, and segment the model if needed.

-

Clear resin 3D printing – Using dedicated SLA/DLP machines.

-

Post-processing – Includes resin washing, UV curing, support removal, polishing, and optional UV coating or dyeing.

-

Quality check and nationwide delivery.

What Products Are Ideal for Clear Resin 3D Printing?

Clear resin is widely used in:

-

Technical components – Valves, pipes, casings, transparent covers.

-

Medical/dental models – Teeth, jawbones, airway tubes, implant simulations.

-

Product packaging – Cosmetic bottles, plastic cases, mock-up gift boxes.

-

Demonstration models – Used in exhibitions, showrooms, or for explaining internal mechanics.

-

Fashion accessories – Rings, pendants, clips, and detailed patterns.

🔍 A major advantage? You can assess internal features without cutting or disassembling the model.

Comparison: 3D printing transparent plastic vs Traditional Prototyping

| Criteria | Clear Resin 3D Printing | CNC Machining / Traditional Molding |

|---|---|---|

| Lead time | 1 – 5 days | 1 – 3 weeks |

| Cost for single prototype | More affordable | Higher |

| Detail resolution | High (up to 25 microns) | Average – depends on workmanship |

| Optimal quantity | Ideal for small batches | Cost-effective only for mass production |

| Design flexibility | Easy to revise & reprint | Difficult – requires new mold |

👉 If you need a fast, clear prototype that shows internal structures — clear resin 3D printing is the top choice.

Why Choose SCANTECH for Clear Resin 3D printing transparent plastic?

SCANTECH is more than just a 3D printing service provider — we’re your technical partner, supporting you from idea to final product.

✅ Cutting-edge high-resolution machines

✅ Expert engineering & support team

✅ CAD design, segmentation & modeling support (if you don’t have a file)

✅ We accept printing from digital files or real samples (via 3D scanning)

✅ Nationwide delivery – fast, on time, and accurate

📞 Contact SCANTECH for a Quotation Today!

Need a transparent prototype, product mock-up, or detailed display model?

🎯 SCANTECH is ready to assist from the very beginning — helping you bring beautiful, accurate, and fast results to life.

📞 Hotline: 0862 170 366

🌐 Website: scantechvn.com

📘 Facebook: facebook.com/scantechvn

📩 Email: ktscantech@gmail.com

OTHER NEWS