Challenges of the wax casting industry

What is wax casting?

Wax casting is a very old casting technique. The wax pattern will burn away to be replaced by metal once the casting process is complete.

Appeared 5000 years ago?

The traditional method of wax casting – creating metal parts from ceramic molds after burning the wax pattern – has been around for more than 5,000 years. Over the centuries, the process has improved greatly, but its application to complex parts remains slow and expensive. Production times are often measured in months and costs can run into hundreds of thousands of dollars.

The wax casting industry is facing challenges related to efficiency, time and capacity despite demand coming from a variety of applications and usage segments.

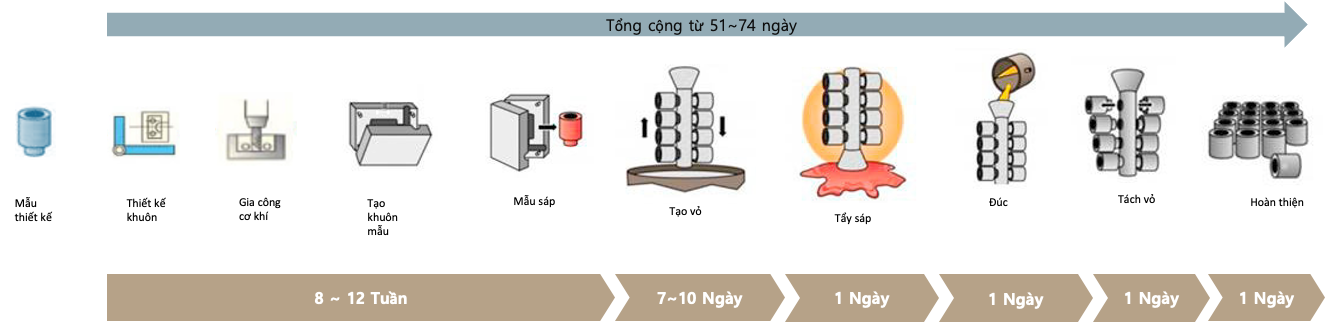

Traditional wax casting process

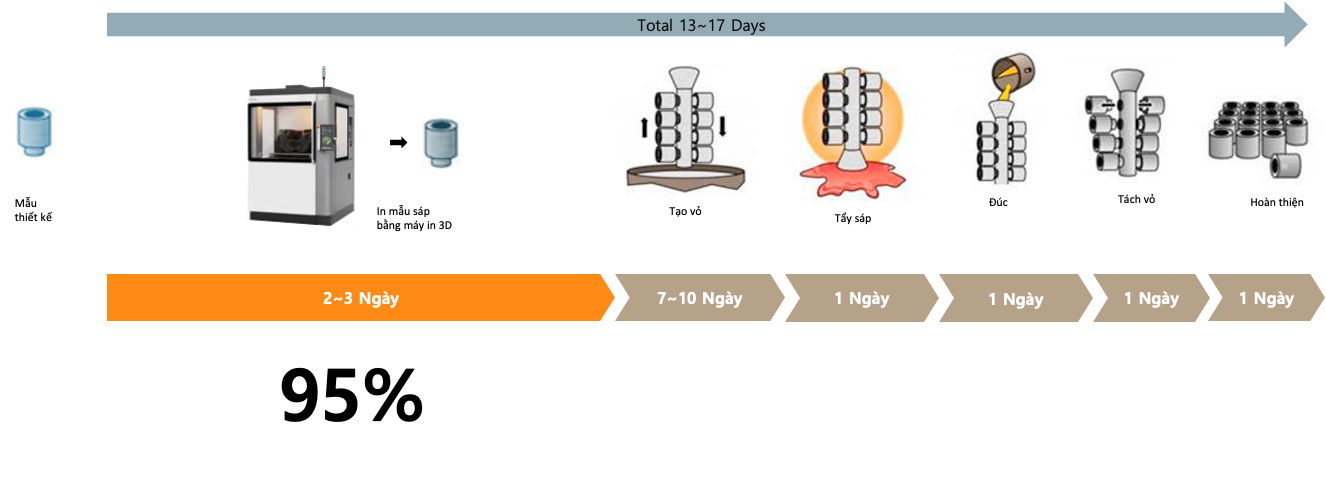

New wax casting process

Compare the two methods above

| Ưu điểm | Defect | |

| 3D printed wax model | •Meets all design requirements •Fast (2~3 days) •Low price (compared to traditional wax modeling method) •Easy to deploy | •Produced in small and medium quantities |

| Traditional wax pattern | •Produced in large quantities •Low raw material prices | •Design limitations when making molds •Long mold manufacturing time (8~12 weeks) •The cost of creating a mold is very high (50,000 – 100,000 USD) •Mold design may have to be changed |

Let’s look forward to part 2 to learn more about 3D Systems’ QuickCast technology.

THANK YOU SO MUCH TO CUSTOMERS AND PARTNERS FOR ALWAYS TRUSTING AND ACCOMPANYING US

Address: BT6-30 Diplomatic Corps, Xuan Tao Ward, Bac Tu Liem District, Hanoi

Hot.line: 0862170366

Email: contact@scantechvn.com / kdscantech@gmail.com

Web: scantechvn.com

OTHER NEWS