3D scanning for jewelry is becoming an indispensable tool in modern design and manufacturing. With the ability to digitize ultra-fine details, replicate complex surfaces, and preserve data with near-perfect accuracy, this technology is ushering in a new era for jewelers, designers, and businesses in the jewelry industry.

Challenges in Traditional Jewelry Design & Manufacturing

Jewelry demands extreme precision, refinement, and creativity, yet traditional crafting still faces major challenges:

-

Difficulty replicating small details: Complex engravings and intricate patterns are nearly impossible to replicate manually without errors.

-

Time & cost-intensive: Trial-and-error in mold making or sample production delays timelines and raises costs.

-

Limited personalization: Consumers increasingly demand unique, one-of-a-kind pieces, but manual methods struggle to deliver quickly.

👉 This is where 3D jewelry scanning demonstrates its superior advantages.

3D Scanners for Jewelry – The Technology Behind Micro-Precision

With non-contact scanning, fast processing, and CAD-ready output, 3D scanners empower jewelers, designers, and businesses to streamline the entire creative workflow.

Artec Micro – Absolute Precision for Miniature Details

-

Accuracy in the micron range (10 microns) – perfect for rings, pendants, and fine engravings.

-

Fully automated scanning system, simple to use, seamlessly integrated into CAD/CAM workflows.

-

Digitized data can be directly 3D printed or used for high-precision mold making.

Artec Space Spider II – Optimized for Complex Surfaces & Patterns

-

Captures highly intricate surfaces like engravings or gemstone settings.

-

Realistic color reproduction.

-

Ideal for design studios requiring both speed and detailed fidelity.

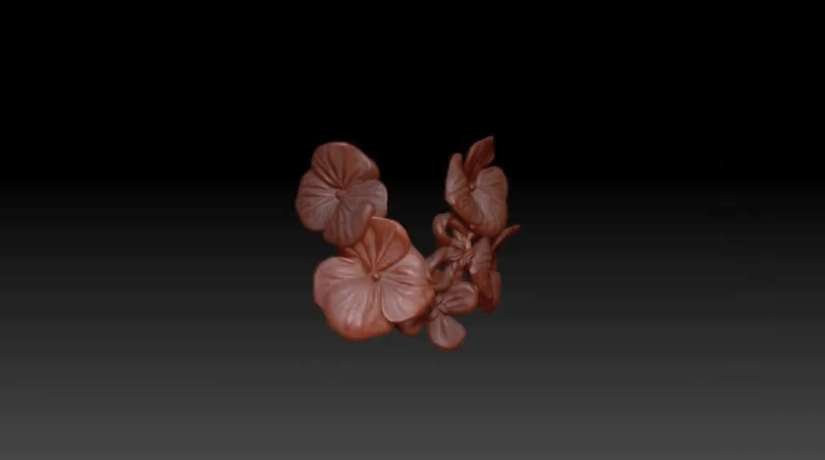

Real-World Application: Scanning a Rose to Create Unique Jewelry

One notable case study showcases how 3D scanning transforms creativity in jewelry: digitizing a real rose to inspire a unique jewelry collection.

-

Speed: Within minutes, the rose was fully digitized.

-

Accuracy: Delicate petals and natural textures were perfectly recreated.

-

Value: The final pieces – rings and necklaces – were one-of-a-kind designs combining natural beauty with industrial precision.

This example shows that 3D scanning is not just a production tool but also an unlimited source of creativity for the jewelry industry.

Benefits of 3D Scanning in Jewelry

-

Save time & cost: Streamlines design, prototyping, and production.

-

High precision: Extremely low error rates ensure final products match designs exactly.

-

Personalization: Easily create bespoke pieces tailored to customer demands.

-

Production flexibility: Integrates with 3D printing, CNC, and mold-making for a fully optimized workflow.

Scantech – Professional 3D Jewelry Scanning Solutions

As a pioneer in 3D scanning in Vietnam, Scantech provides comprehensive solutions for jewelers and jewelry businesses:

-

Tailored technology consultation: From Artec Micro for miniature precision to Artec Eva for larger, flexible models.

-

Hands-on experience: Clients can register for live demos and test their products directly.

-

Long-term partnership: Technical support, user training, and continuous software upgrades.

👉 Looking for a 3D jewelry scanning solution to elevate your design and manufacturing?

Contact Scantech today for consultation and a free demo.

📞 Hotline: +84 904 985 139 / +84 912 469 168

📧 Email: kdscantech@gmail.com

🌐 Website: https://scantechvn.com

📘 Fanpage: facebook.com/scantechvn

🏢 Showroom: BT6-30 Ngoai Giao Doan, Xuan Dinh Ward, Hanoi

OTHER NEWS