From the current reality of 3D printing technology, Scantech will advise and present to customers the wonderful things that 3D printing technology has done and brought to the world:

- 3D printing technology is one of the new development trends of science and technology.

- Thanks to 3D printing technology, we will be able to manufacture objects at a much cheaper price and in a much shorter time.

- The application of 3D printing technology is very wide, from construction, fashion, medicine, to industries such as automobile, aircraft, and aerospace manufacturing.

In the early 1980s, an engineer named Chuck Hall had a very special idea about a machine that could print 3D shapes. The idea was considered by many people to be far-fetched at that time, only in science fiction works. However, up to now, 3D printing technology has not only become a reality but its applications have also gone beyond what we can imagine.

- Clothing design

You may not know, in the 2013 Victoria’s Secret show, a sparkling accessory and a crown worn by model Lindsay Ellingson were products of 3D printing technology. 3D printing technology promises to change the fashion and apparel industry worldwide.

According to fashion designer Iris van Herpen, in the near future we will use body scanners, then create clothing models suitable for each person based on 3D printing technology. Not only that, users can customize their clothes to their liking down to every millimeter accurately. Besides, 3D printing technology also promises to completely change the fashion accessories industry.

- Cheap prosthetic limbs

With today’s advanced medicine, those who are unlucky enough to lose their arms or legs have the opportunity to function normally with flexible prosthetic limbs. However, their cost is not cheap, it can be up to thousands of dollars.

With 3D printing technology, Mick Ebeling – CEO of research company Not Impossible Labs – has created for the first time prosthetic limbs that cost only about 100 USD. Scientists at design company Autodesk and the University of Toronto are developing software that allows scanning the body parts of amputees, then designing replacement parts that are most suitable at low cost.

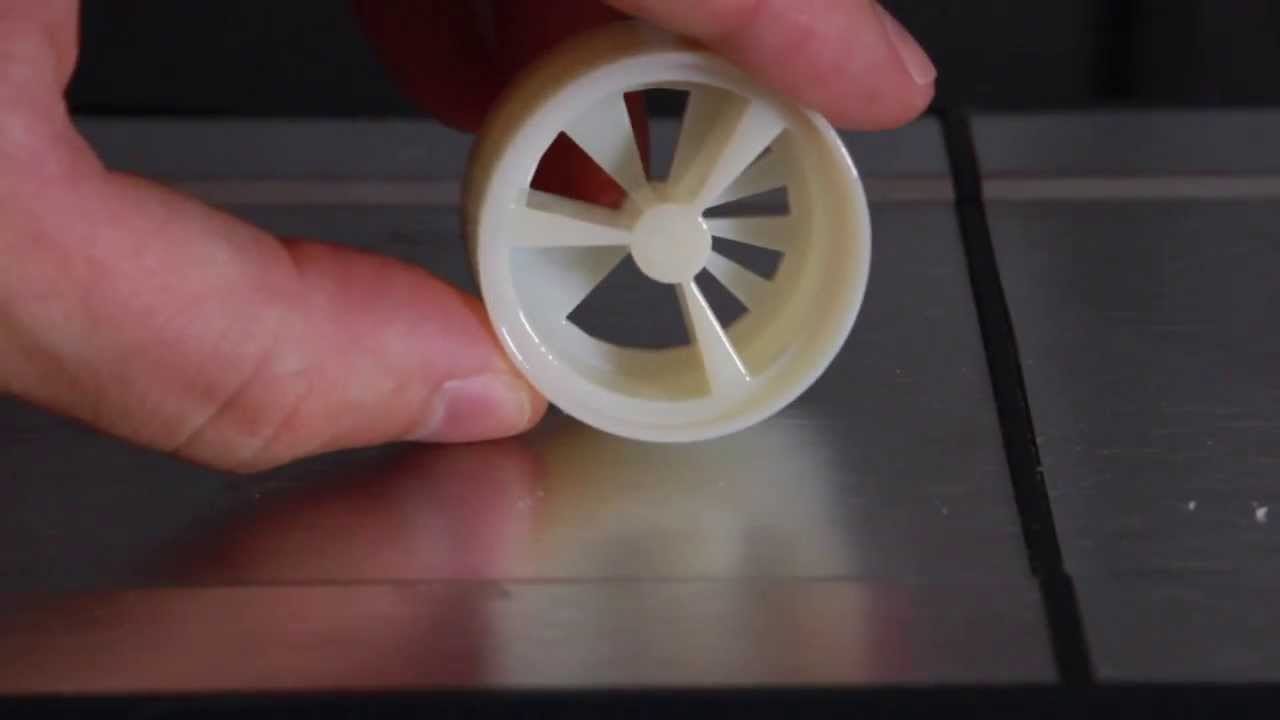

- Replacement parts for everything

Electronic devices, or any object around us, can have some parts broken. Usually, if we cannot fix it, we will have to replace it with new parts. However, finding and replacing components is not always simple, maybe because your item is too old and no longer produced.

However, with 3D printing technology, all these problems can be easily solved. Now you can download the design files of those components, then use a 3D printer at home to create a completely new one to replace it. Currently, on the Thingiverse website, there are designs for more than 2,500 replacement components for everything from car window cranks, wristwatches or some other electronic components …

- Food

Not only stopping at making objects, 3D printing technology also helps you create special foods, including candies. At last year’s Consumer Electronics Show in Las Vegas, 3D Systems debuted a 3D printer that can use chocolate, sugar, vanilla, and flavorings to create a variety of interesting candy shapes.

But it’s not the only company using 3D printers to create food. Natural Machines has also introduced a 3D printer called Foodini that can “print” pasta. Dovetailed is another company that has used 3D printing to create fruit with unique flavors.

- Construction

A Chinese construction company says it has used 3D printing technology to build houses. It uses a giant 3D printer to spray cement and a recycled material instead of the conventional concrete used to build houses. Houses built with 3D technology do not have very beautiful designs and large sizes, but their prices are quite cheap, only about 5000 USD per house. Besides, the time to complete a house built with 3D printing technology is very fast, this company has completed 10 houses in just one day.Manufacturing organs for transplantation inside the body

Scientists have made a major breakthrough in transplanting organs inside the human body using 3D printing technology, called bioprinting. In it, scientists have taken human cells from biopsies or stem cells, cloned them in petit dish, then used them as a biological ink to create human internal organs such as heart, kidney …

Scientists hope that bioprinting will be able to arrange cells precisely to completely simulate the functions of organs inside the body. These artificial organs could be used to test drugs, or even to replace real organs. If these organs are created from the patient’s own stem cells, they will have less risk of being rejected by that person’s immune system.

- Car Manufacturing

Car parts made with 3D printing technology have been used for a while, but engineer Jim Kor and his colleagues had a bolder idea when they built an entire car using 3D printing technology. The car was produced in 2013, has two wheels and can carry two passengers, with details made mainly from plastic thanks to a 3D printer. The car is equipped with a hybrid engine made of iron.

Although Jim Kor’s car may not be perfect, it opens up a new direction for the automobile manufacturing industry. With 3D printing technology, cars can be made from a material that is cheap, light and as strong as iron and steel, while being easy to process and create lines.

A concept model of a car made with 3D printing technology.

- Art

In addition to being used in science and industry, 3D printing technology is also used by artists to create unique works of art. Artist Cosmo Wenman once used a 3D printer to create an extremely detailed replica of the famous sculpture “Head of a Horse of Selene”.

He used a 3D printer to create different parts of the statue’s face, then assembled them with glue and marble paint to simulate this work of art. In the future, works of art will be digitized and everyone can download and create a perfect copy with a 3D printer, of course all of these works are made of plastic.

- Weapons

In 2013, a designer in Texas successfully created a pistol that can shoot real bullets using 3D printing technology. The gun is made of plastic, but some parts are made of metal because the designer feared it would become a weapon that could be carried through airport security. This application of 3D technology brings many risks, when anyone can download the design online and make a gun for themselves.

However, military experts consider this a useful invention, when the cost of making weapons from conventional materials is very high. Using 3D printing technology will help create new weapons at low cost and in a very short time. Soldiers will not even have to carry weapons to the battlefield, but can use 3D printers to create them right there.

- 3D printing technology will change the world

Besides nanotechnology, 3D printing technology is one of the new development trends of science and technology. Its applications are huge, it can completely change the way we create everyday objects. Can you imagine the scenario of going to a 3D printing shop with a design in hand to print a detail of something, and in less than 5 minutes you have exactly what you need in your hand, how do you feel?

Currently, Scantech company almost has printers to meet the printing needs of the objects listed above. You can come and experience what you want to print at Scantech.

OTHER NEWS