🔍 What is MJP 3D Printing?

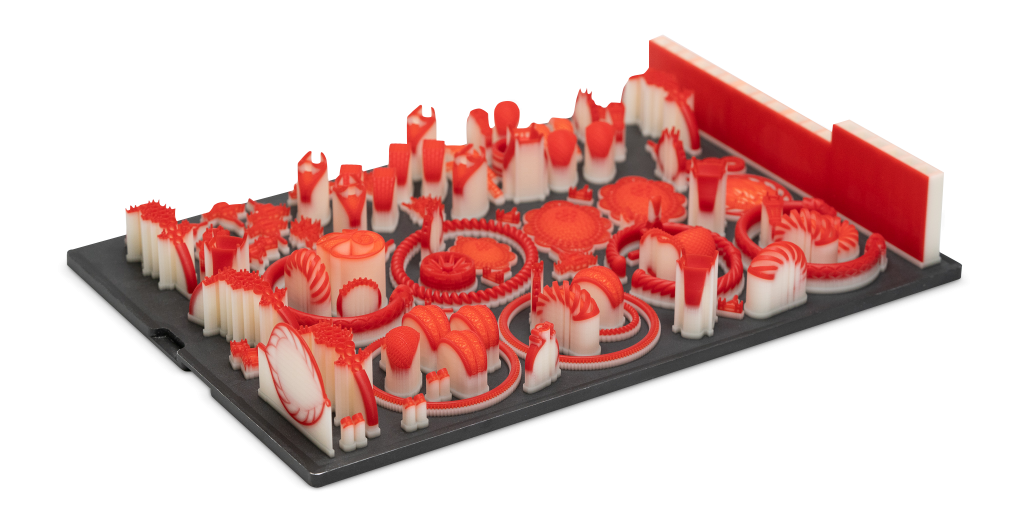

MJP (MultiJet Printing) is a 3D printing technology that uses micro nozzles to deposit material layer by layer with ultra-high precision – similar to 2D inkjet printing but in three dimensions. What sets MJP apart is its ability to print both build and support materials simultaneously, enabling highly complex geometries with ultra-smooth surfaces and details down to the micrometer.

🔍 What is SLA 3D Printing?

SLA (Stereolithography) uses UV lasers to cure liquid resin layer by layer. It stands out for its fast printing speed and good resolution, making it suitable for technical models, display prototypes, and large-sized parts.

MJP vs SLA – Which Produces Smoother Results?

| Criteria | MJP 3D Printing | SLA 3D Printing |

|---|---|---|

| Sharpness | Extremely high – captures details < 0.01mm | High – may leave slight layer lines |

| Surface smoothness | Nearly perfect – no visible layering | May need post-processing to smooth surface |

| Materials used | Thermoset resins – many types for different uses | Standard resins – heat-resistant or transparent |

| Printing speed | Slower – ultra-thin layers take more time | Faster – especially for larger print areas |

| Support removal | Easy – wax support dissolves completely | Manual removal and sanding required |

| Best applications | High-end models, micro parts, dental, watches, jewelry | Engineering models, technical prototypes, large parts |

⭐ Why Choose MJP for Ultra-Detailed 3D Prints?

If you’re printing tiny parts with fine grooves, complex textures, or need smooth surfaces right off the printer without polishing, MJP is the ultimate choice.

At SCANTECH, MJP technology is applied in:

💍 Jewelry – Luxury Watches:

Print high-detail wax patterns for casting precious metals (gold, silver, platinum), with precise engravings, twisted grooves, and micro text.

⚙️ Small Mechanical Components:

Create prototype parts such as mini gears, casings, connectors, with accuracy up to ±0.01 mm, suitable for test fitting and functional validation before mass production.

📦 Packaging & Consumer Product Samples:

Print cosmetic boxes, sample bottles, caps with high gloss and sharp details – ideal for evaluating aesthetics, proportions, and user experience before market launch.

🦷 Dental & Digital Healthcare:

Produce dental models, crowns, orthodontic trays, surgical guides with excellent surface quality for training, clinical simulation, and fitting tests.

✅ When to Choose SLA 3D Printing?

SLA is still a great option if you need:

-

Fast turnaround time for medium-scale production

-

Cost-effective printing for large models

-

Technical or display models where mid-level detail is acceptable

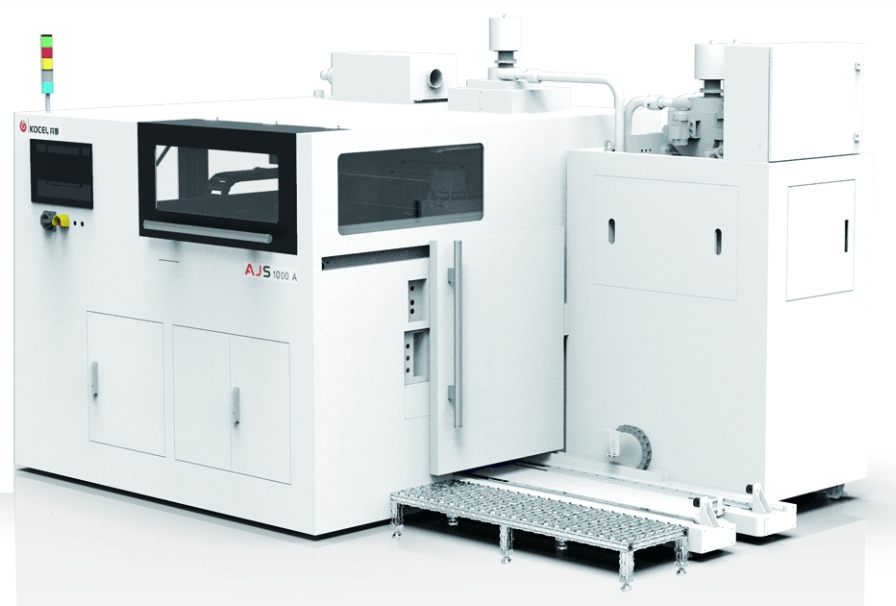

At SCANTECH, we use industrial-grade SLA systems to print:

🛠 Engineering Models:

Enclosures, brackets, assemblies

🧠 Medical Models:

Anatomical bones, large-scale medical structures

🚗 Industrial Demonstration Products:

Radar systems, automotive shells, mechanical displays

MJP or SLA – Which to Choose?

Choose MJP if:

✅ You need extremely fine details

✅ Smooth surface finish right off the printer

✅ Small-sized, high-end models

✅ You’re printing jewelry, watches, or medical parts

Choose SLA if:

✅ You’re printing larger models with medium detail

✅ You need faster print times and lower costs

✅ You’re creating engineering or display prototypes

🏆 SCANTECH – Professional 3D Printing with MJP & SLA

We don’t just print – we consult to help you choose the right technology, materials, timing, and budget for your project.

✅ Equipped with both MJP & SLA systems

✅ Support for file preparation, part splitting, and CAD cleanup

✅ Guaranteed accurate models – on time – with quality assurance

📞 Contact us now for a free consultation on the best 3D printing solution for your needs!

-

Hotline: 0862 170 366

-

Website: scantechvn.com

-

Facebook: facebook.com/scantechvn

-

Email: ktscantech@gmail.com

OTHER NEWS