3D Printing Today: Beyond Prototyping

n modern manufacturing, 3D printing (Additive Manufacturing) is no longer limited to prototyping — it has evolved into a diverse ecosystem of technologies, each with unique principles, materials, and industrial applications.

Understanding the differences between 3D printing technologies helps businesses choose the right solution for their goals — whether it’s speed, strength, surface quality, or cost optimization.

This guide provides a detailed 3D printing comparison of leading methods such as FDM, SLA, MJP, SLS, DMP, Binder Jetting, and MJF, along with real-world use cases across industries like automotive, aerospace, medical, mold making, and R&D.

By the end, you’ll know exactly which 3D printing technology best fits your production needs.

FDM – Fused Deposition Modeling

Principle:

FDM (Fused Deposition Modeling) works by extruding melted thermoplastic filament through a heated nozzle, building the object layer by layer according to its geometry.

Common Materials:

PLA, ABS, PETG, Nylon, PETG-CF (carbon fiber-reinforced composite).

Advantages:

✅ Low cost and easy operation

✅ Large build volume

✅ Wide range of mechanical-grade materials available

Limitations:

-

Visible layer lines and limited surface quality

-

Lower accuracy compared to resin or laser-based methods

-

Weaker strength along the Z-axis

Typical Applications:

-

Manufacturing & Tooling: Custom jigs, fixtures, and assembly aids for production lines.

-

R&D / Prototyping: Functional prototypes for fit and assembly testing.

-

Education / Labs: Demonstration models and hands-on training samples.

When to Choose FDM:

If you need large parts, functional strength, and cost efficiency, FDM remains the most practical 3D printing technology for rapid prototyping and industrial mockups.

SLA (Stereolithography)

|

|

|

|

|

|

Principle:

Uses a UV laser to cure liquid resin, solidifying each layer precisely.

Materials:

Standard resin, heat-resistant resin, biocompatible resin, transparent resin.

Advantages:

✅ Extremely high resolution (±0.05 mm)

✅ Smooth surface finish and excellent aesthetics

Limitations:

-

Brittle material properties

-

Requires washing and post-curing

-

Higher resin cost

Applications:

Design prototypes, dental models, silicone molds, and intricate presentation pieces.

When to Choose SLA:

When you need maximum surface quality and detailed visual models.

MJP (MultiJet Printing)

|

|

|

Principle:

Deposits droplets of UV-curable resin through multiple print heads, solidified by UV light — enabling multi-material printing in a single build.

Materials:

Rigid and flexible resins, wax-based support materials.

Advantages:

✅ Ultra-smooth surfaces and high precision

✅ Ability to print with multiple materials and colors simultaneously

Limitations:

-

Smaller build volume

-

High equipment and material costs

Applications:

High-end product design, functional prototypes, precision medical models.

When to Choose MJP:

Ideal for multi-material models and fine detail where realism and precision are critical.

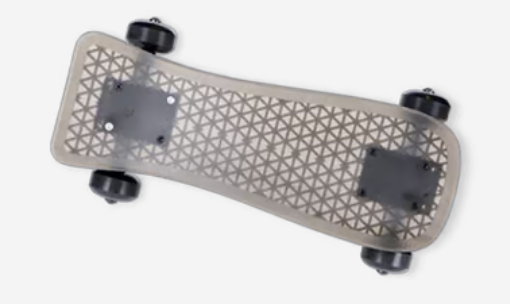

SLS – Selective Laser Sintering

|

|

Principle:

A high-powered laser fuses layers of polymer powder (typically nylon-based) into solid parts. The surrounding powder acts as natural support, eliminating the need for external supports.

Materials:

PA11, PA12 (nylon), TPU, glass- or carbon-fiber–reinforced polymers.

Advantages:

✅ Excellent mechanical strength and heat resistance

✅ No support structures needed

✅ Complex internal geometries possible

Limitations:

-

Slightly rough surface texture

-

Higher material cost

-

Requires careful powder handling and safety measures

Applications:

-

Automotive & Aerospace: Functional parts, interior panels, and lightweight structural components.

-

Low-volume Manufacturing: End-use parts, replacement components, durable jigs.

When to Choose SLS:

If your project requires functional, durable parts or low-volume production, SLS is the ideal choice in the 3D printing comparison lineup.

DMP / SLM / DMLS – Direct Metal 3D Printing

|

|

Principle:

Also known as Metal Additive Manufacturing, DMP (Direct Metal Printing) uses a laser or electron beam to melt fine layers of metal powder, building fully dense metal parts.

Materials:

Stainless steel, aluminum, titanium (Ti6Al4V), Inconel, cobalt-chrome alloys.

Advantages:

✅ True metal mechanical properties

✅ Ideal for high-performance and lightweight parts

✅ Enables designs impossible with traditional machining

Limitations:

-

High cost (machines, metal powder, and post-processing)

-

Requires heat treatment and finishing

-

Safety protocols for metal powder handling

Applications:

-

Aerospace: Lightweight titanium brackets and load-bearing components.

-

Medical: Custom titanium implants and surgical tools.

-

Automotive & R&D: Functional metal prototypes and precision inserts for molds.

When to Choose DMP:

When you need end-use metal parts with high strength, precision, and complex geometry — DMP is the gold standard of metal 3D printing.

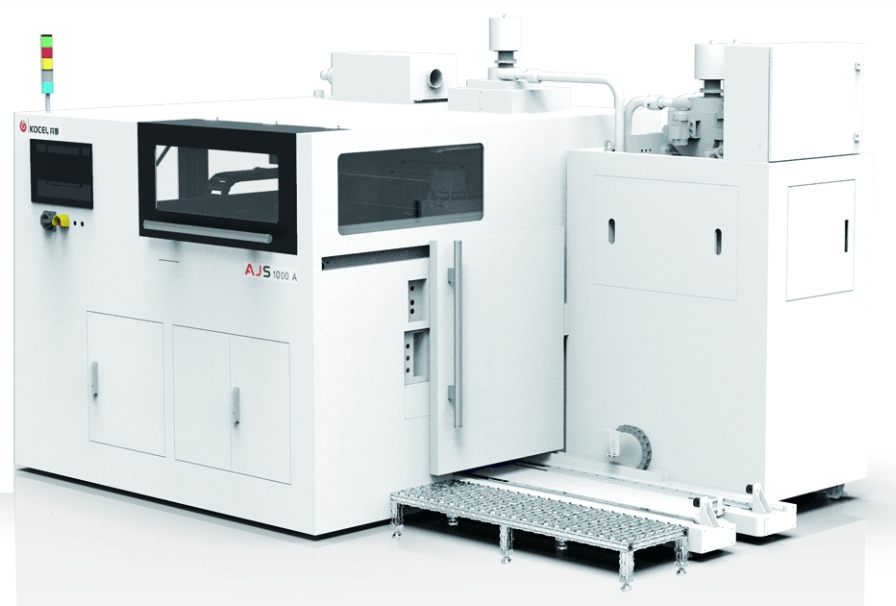

Binder Jetting

|

|

Principle:

Applies a liquid binding agent to layers of sand or metal powder, later hardened through sintering, casting, or infiltration.

Materials:

Silica sand, metal powders (steel, aluminum), and ceramics.

Advantages:

✅ Extremely fast build speeds

✅ Large-scale printing capability

✅ Lower cost per part at production scale

Limitations:

-

Requires post-processing (sintering or casting)

-

Slightly lower accuracy than laser-based systems

Applications:

Sand molds for casting, large prototypes, industrial patterns, or metal parts after sintering.

When to Choose Binder Jetting:

Best for high-speed, large-format production of molds or mid-volume industrial parts.

🧠 3D Printing Comparison Summary Table

| Criteria | FDM | SLA | MJP | SLS | DMP (Metal) | Binder Jetting / MJF |

|---|---|---|---|---|---|---|

| Accuracy | Medium | Very High | Very High | High | Very High | Medium |

| Surface Finish | Layered | Smooth | Smooth | Slightly Rough | Smooth (post-processed) | Rough / requires finishing |

| Strength | Good | Low | Low-Medium | High | Very High | High (after sintering) |

| Build Volume | Large | Medium | Small-Medium | Medium | Small-Medium | Very Large |

| Speed | Medium | Slow | Medium | Medium | Slow | Fast |

| Cost | Low | Medium | High | High | Very High | Medium |

| Typical Use | Jigs, prototypes | Dental, jewelry | High-end design | Functional parts | Metal production | Molds, large parts |

🧭 How to Choose the Right 3D Printing Technology

-

Need metal end-use parts → Choose DMP

-

Need durable plastic parts or low-volume production → Choose SLS

-

Need fine detail and smooth surfaces → Choose SLA or MJP

-

Need large parts at low cost → Choose FDM

-

Need molds or large industrial patterns → Choose Binder Jetting / MJF

Pro Tip:

There’s no single “best” 3D printing method — only the one that fits your materials, mechanical requirements, budget, and production goals.

🔧 Industry Applications of 3D Printing Technologies

Manufacturing & R&D

3D printing accelerates product design, testing, and production.

-

FDM/SLS: Durable jigs and fixtures

-

SLA/MJP: Visual and ergonomic prototypes

-

Binder Jetting: Casting molds

-

DMP: Functional metal inserts

Result: Reduce product development time by up to 70%, cut R&D costs by 50%.

Automotive & Electric Vehicles

From concept to pilot production, 3D printing empowers faster iteration.

-

SLA/MJP: Aesthetic parts and assemblies

-

FDM/SLS: Technical and structural prototypes

-

DMP: Heat-resistant and load-bearing parts

-

Binder Jetting: Aluminum or steel molds

Aerospace

High precision and lightweight structures define aerospace manufacturing.

-

SLS: Functional prototypes and housings

-

DMP: Lightweight titanium or Inconel parts

-

Binder Jetting: Casting molds for composite components

Result: Reduce part weight by up to 60% while maintaining strength.

Medical & Dental

Personalized, high-precision solutions through additive manufacturing.

-

SLA/MJP: Orthodontic trays, surgical guides, biological models

-

SLS: Durable biomedical-grade polymer tools

-

DMP: Custom titanium implants and prosthetics

Mold & Casting Industry

3D printed molds shorten lead times and enhance customization.

-

FDM/SLA/SLS: Prototype molds

-

MJP: Precision jewelry or wax molds

-

Binder Jetting: Complex sand molds

-

DMP: Metal inserts with conformal cooling channels

Education & Research

Empowering universities and labs to train the next generation of engineers.

-

FDM/SLS: Functional teaching models

-

SLA/MJP: Demonstration-grade prototypes

-

DMP/Binder Jetting: Material and process research

❓ Quick FAQ – 3D Printing Comparison

1. Can SLS print metal?

No, SLS is for polymers. Metal printing uses DMP/SLM/DMLS.

2. How is Binder Jetting different from SLS?

Binder Jetting uses a binding agent instead of a laser — faster, but requires sintering.

3. Which technology is the most accurate?

SLA, MJP, and DMP provide the highest accuracy for detailed industrial and medical components.

4. Which is the fastest and most cost-effective?

FDM and Binder Jetting/MJF — ideal for large-scale or low-cost prototyping.

5. Can multiple 3D printing technologies be used in one project?

Yes! Many companies combine 3D scanning + CAD + SLA + DMP + QA inspection for a fully optimized workflow.

🚀 Conclusion: Choosing the Right 3D Printing Technology

Selecting the right 3D printing method is a strategic decision — there’s no one-size-fits-all.

By understanding your material, mechanical, size, and cost requirements, you can choose the best solution for your business.

Scantech VN offers consultation, sample testing, and project optimization services to help you identify the most effective technology for your goals.

📞 Hotline: 0904 985 139 / 0862 170 366

📧 Email: ktscantech@gmail.com

🌐 Website: https://scantechvn.com

📘 Facebook: facebook.com/scantechvn

🏢 Showroom: BT6-30 Ngoai Giao Doan, Xuan Dinh, Ha Noi.

OTHER NEWS