In the world of 3D printing, the demand goes beyond rapid prototyping to require sharp details, smooth surfaces, and near-perfect accuracy. 3D MJP (MultiJet Printing) technology meets all these criteria, and at Scantech, we elevate MJP to the next level with international-standard processes and superior output quality.

1. MJP – True Premium 3D Printing

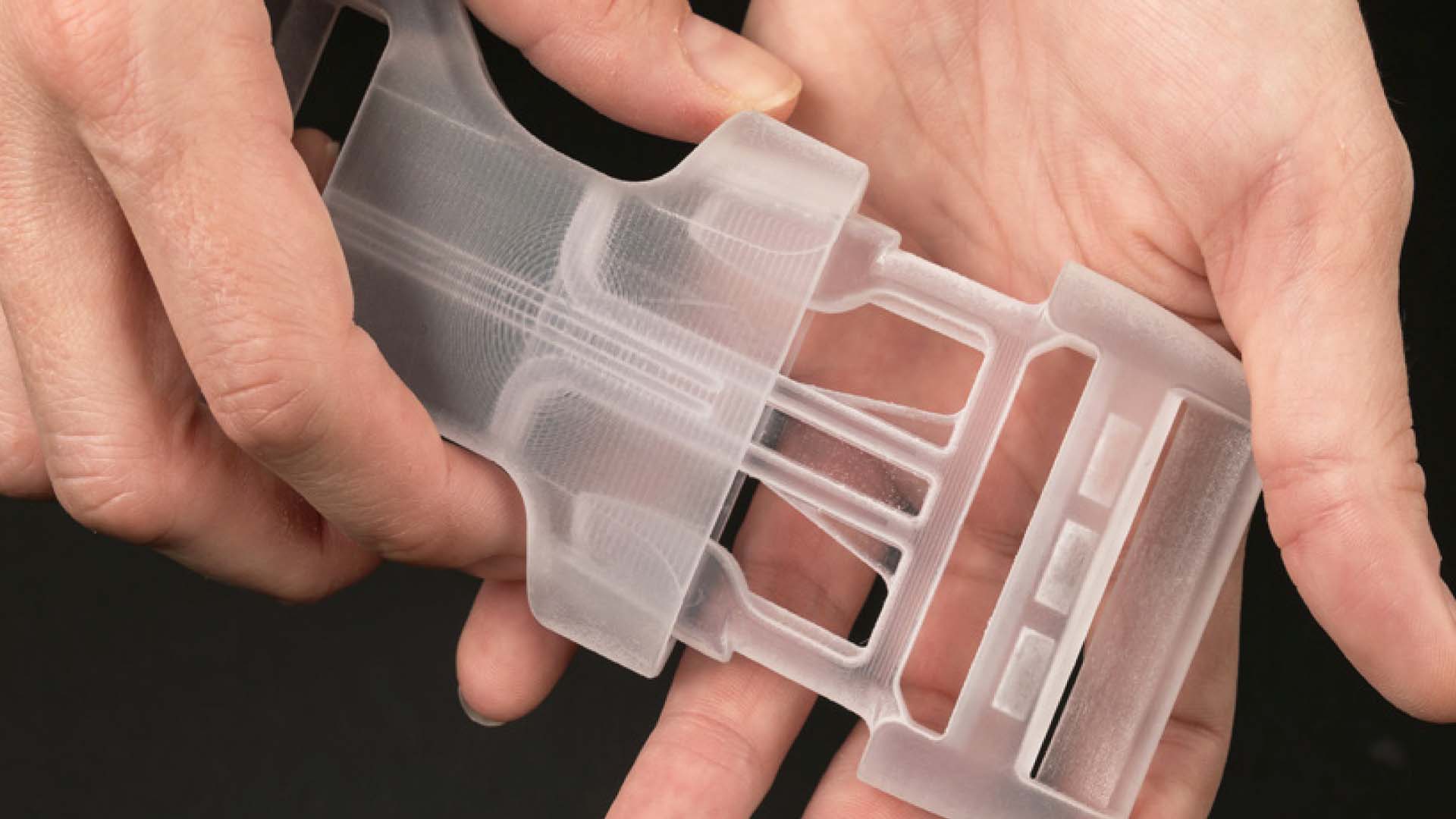

Unlike SLA or SLS, MJP uses multiple ultra-fine nozzles to jet material at a layer thickness of only 16 microns, delivering products with:

-

Exceptional detail – capturing every edge and contour with precision.

-

Ultra-smooth surfaces – minimizing post-processing work.

-

Consistent mechanical strength – suitable for both technical testing and high-end display.

Compared to SLA and SLS:

-

Smoother than SLA: SLA creates smooth surfaces but still needs polishing; MJP delivers near-finished surfaces right out of the printer.

-

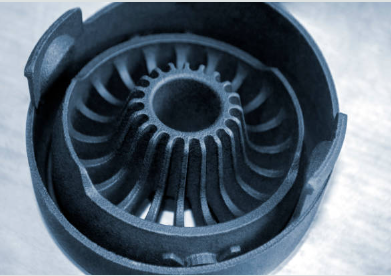

More detailed than SLS: SLS is fast but cannot match MJP’s fine resolution.

2. Real-World Applications of MJP

-

Industrial Engineering: High-precision mechanical components down to the micron level.

-

Medical: Surgical models, medical device prototypes with highly accurate anatomical details.

-

Jewelry: Intricate designs before mass production.

3. Why Choose 3D MJP Printing Service

Compared to SLA and SLS, MJP stands out with:

-

Ultra-high resolution: Prints micro-scale details with minimal manual finishing.

-

Smooth surfaces: Saves time on polishing compared to SLS.

-

Technical-grade materials: Durable, heat-resistant resins for functional prototypes.

-

High speed: Print multiple models simultaneously without sacrificing quality.

-

Cross-industry applications: Engineering, healthcare, jewelry—all benefit from MJP’s precision.

4. MJP vs. SLA and SLS Comparison

| Criteria | SLA | SLS | MJP (Scantech) |

|---|---|---|---|

| Detail accuracy | High | Medium | Very High |

| Surface quality | Smooth but needs finishing | Rougher | Ultra-smooth, minimal finishing |

| Durability | Good | Excellent | Good & consistent |

| Application suitability | Basic prototypes | Mechanical parts | High-end, detailed models |

5. 3D MJP Printing Process at Scantech

-

Receive customer requirements and recommend suitable printing technology.

-

Process 3D files and optimize the design.

-

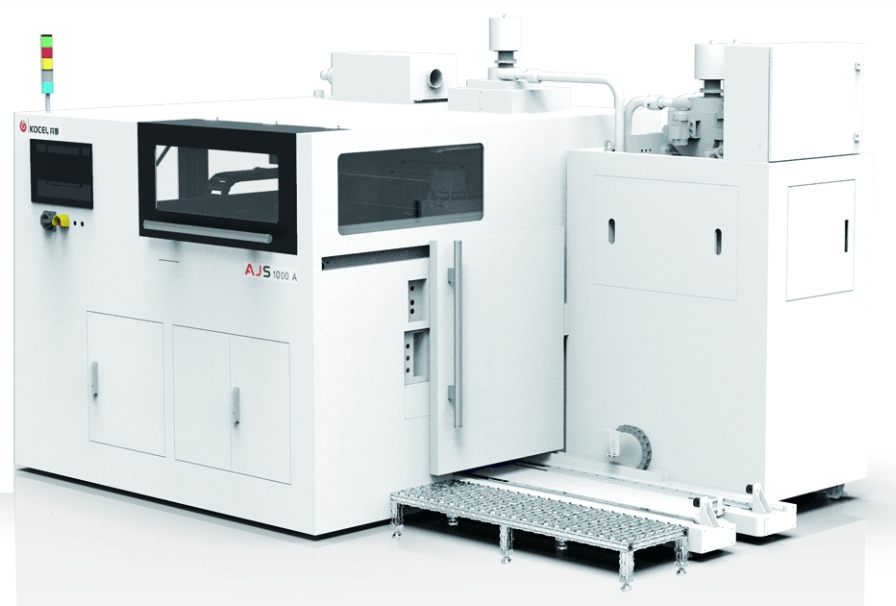

Print using industrial-grade MJP printers.

-

Conduct quality checks and deliver the final product.

With Scantech’s premium 3D MJP Printing Service, your business will receive high-precision, professional-quality models—setting a new standard compared to conventional SLA or SLS technologies.

📍 Hotline: 0862 170 366

🌐 Website: scantechvn.com

📩 Email: ktscantech@gmail.com

📱 Facebook: facebook.com/scantechvn

OTHER NEWS